-

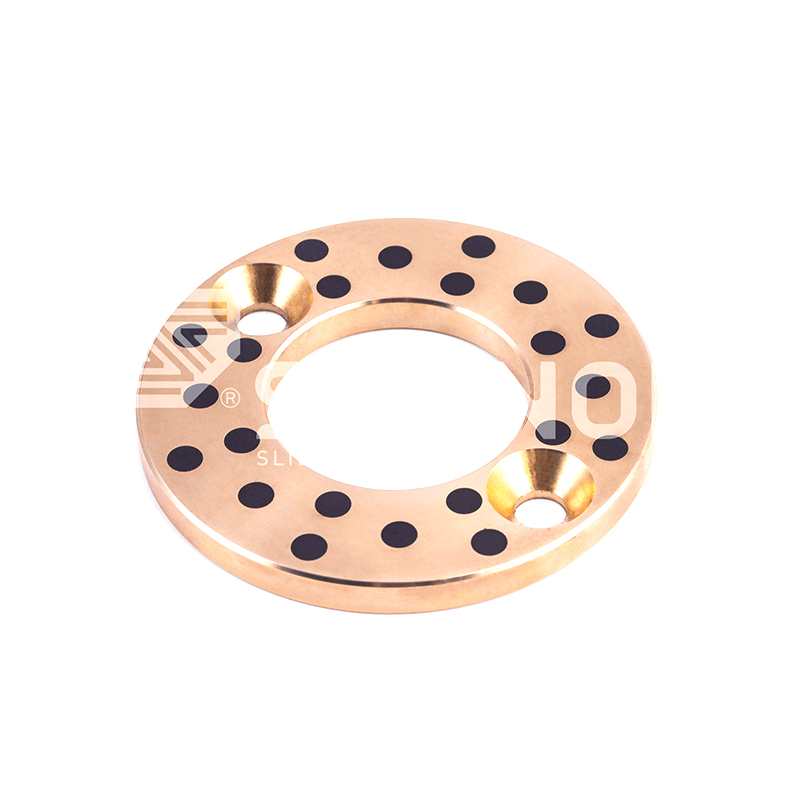

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing -

JDB Solid-lubricating Bearing JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing

JDB Solid-lubricating Bearing JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing -

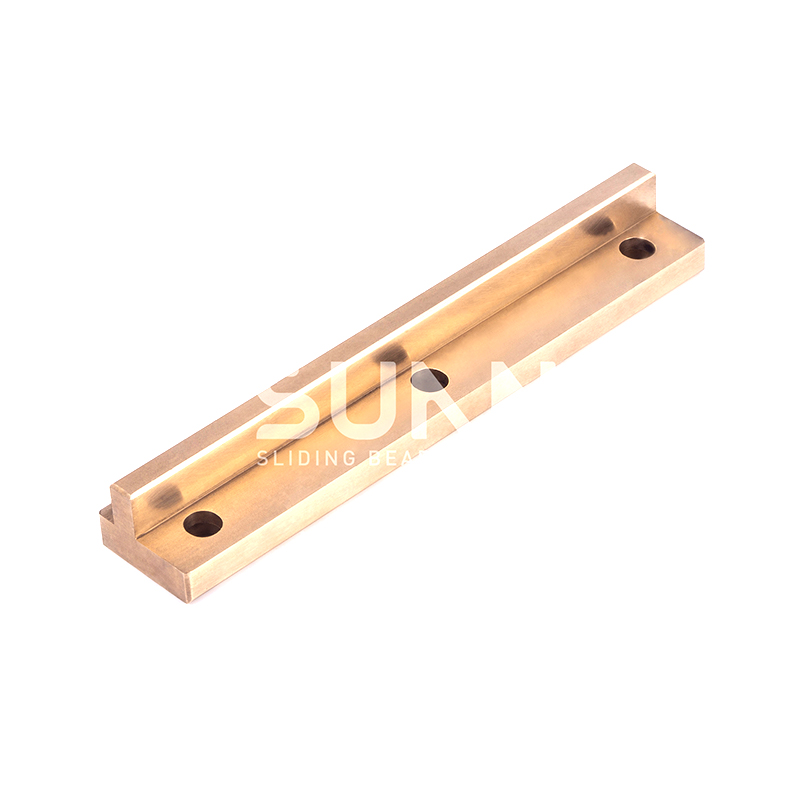

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components -

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed)

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed) -

SF-1 Oilless Bearing Maintenance-Free SF-1W Wall Wrapped Lead-Free Bronze Bearing Oilless Bearing Bush

SF-1 Oilless Bearing Maintenance-Free SF-1W Wall Wrapped Lead-Free Bronze Bearing Oilless Bearing Bush -

-

SF-2 Boundary Lubricating Bearing SF-2Y Boundary Self-lubricating Bearing - Low Friction Dry Lubricant Bushings for Industrial Machinery

SF-2 Boundary Lubricating Bearing SF-2Y Boundary Self-lubricating Bearing - Low Friction Dry Lubricant Bushings for Industrial Machinery -

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers

Solid Lube Bearings: A Comprehensive Guide to Maintenance-Free Solutions

Industry News-Solid lube bearings are an innovative class of bearings designed to operate without the need for liquid or grease lubrication. These bearings are widely used in extreme environments where traditional lubricants fail, such as high temperatures, vacuum conditions, or heavily contaminated settings. This article explores two key variants—solid grease bearings and solid-lubricating bearings—comparing their properties, applications, and performance data.

Solid Grease Bearings: Pre-Lubricated for Extended Service Life

Solid grease bearings are a hybrid solution where a solid lubricant (such as graphite or PTFE) is embedded within a grease-like matrix. These bearings are pre-lubricated during manufacturing, ensuring long-term performance without the need for frequent re-lubrication.

Key Features:

Self-lubricating: Reduces maintenance requirements.

Wide temperature range: Operates in -40°C to 250°C environments.

Contaminant resistance: Performs well in dusty or wet conditions.

Applications:

Food processing machinery (FDA-compliant lubricants)

Automotive components (bushings, suspension parts)

Industrial machinery in harsh environments

Performance Data Comparison (Solid Grease vs. Traditional Grease Bearings)

| Parameter | Solid Grease Bearings | Traditional Grease Bearings |

|---|---|---|

| Relubrication Interval | 5,000+ hours | 500–1,000 hours |

| Max Temperature | 250°C | 120°C |

| Friction Coefficient | 0.08–0.12 | 0.10–0.15 |

Solid-Lubricating Bearings: Dry Lubrication for Extreme Conditions

Solid-lubricating bearings rely entirely on dry lubricants (e.g., molybdenum disulfide, graphite, or PTFE) embedded in the bearing material. These bearings eliminate the risk of lubricant degradation, making them ideal for aerospace, vacuum systems, and high-load applications.

JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing

Key Features:

No external lubrication needed: Operates in dry or vacuum conditions.

High load capacity: Supports heavy machinery without lubricant breakdown.

Corrosion-resistant: Suitable for marine and chemical industries.

Applications:

Spacecraft mechanisms (satellites, rovers)

High-vacuum industrial equipment

Mining and construction machinery

Performance Data Comparison (Solid-Lubricating vs. Oil-Lubricated Bearings)

| Parameter | Solid-Lubricating Bearings | Oil-Lubricated Bearings |

|---|---|---|

| Maintenance Needs | None | Frequent oil changes |

| Max Temperature | 350°C+ | 150°C |

| Wear Rate | Low (0.001 mm³/Nm) | Moderate (0.005 mm³/Nm) |

| Contaminant Sensitivity | Highly resistant | Vulnerable to contamination |

| Typical Lifespan | 20,000+ hours | 5,000-8,000 hours |