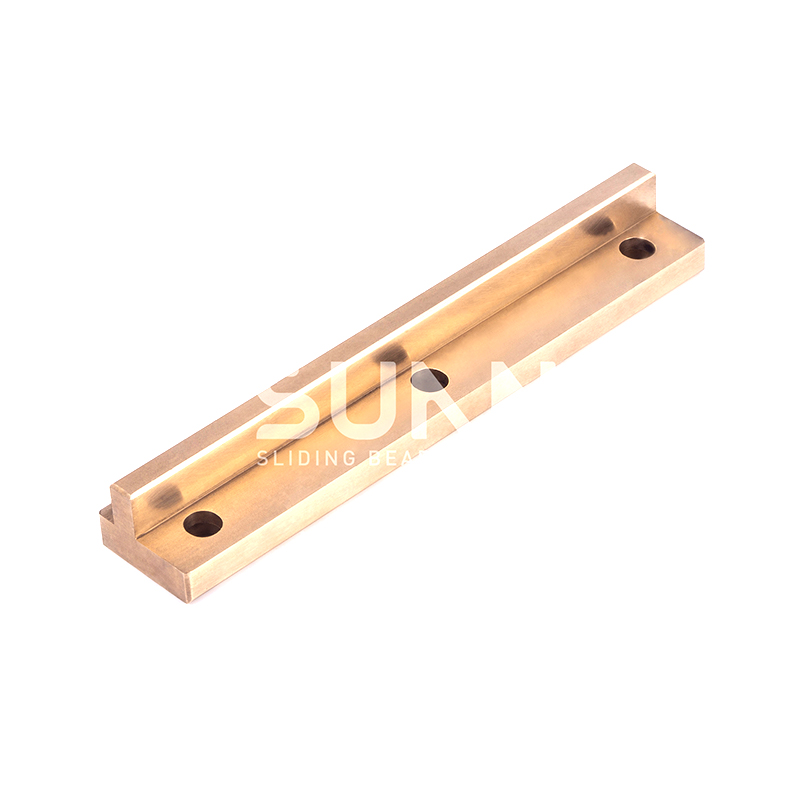

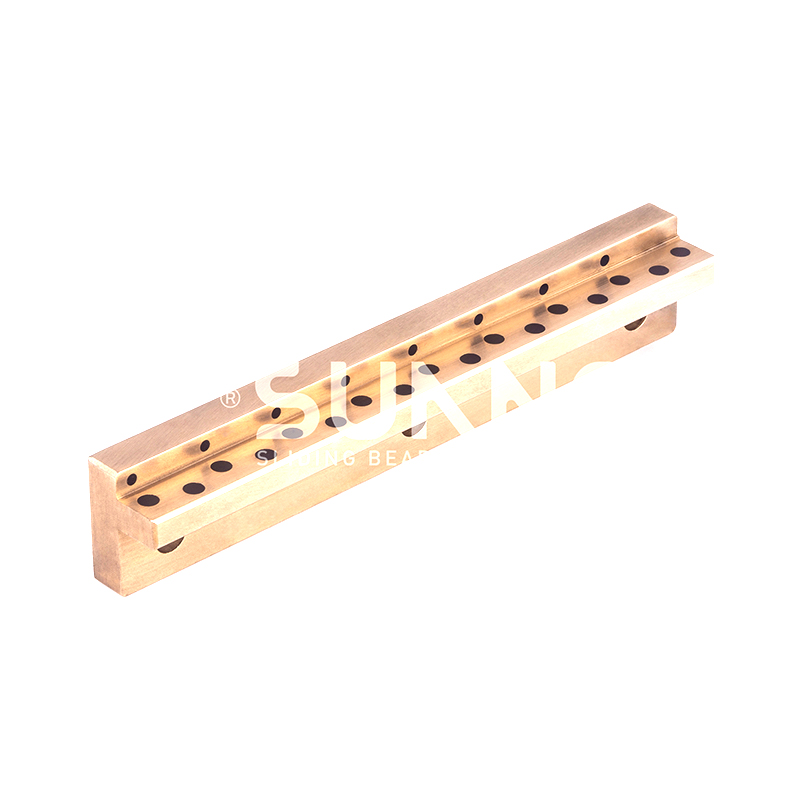

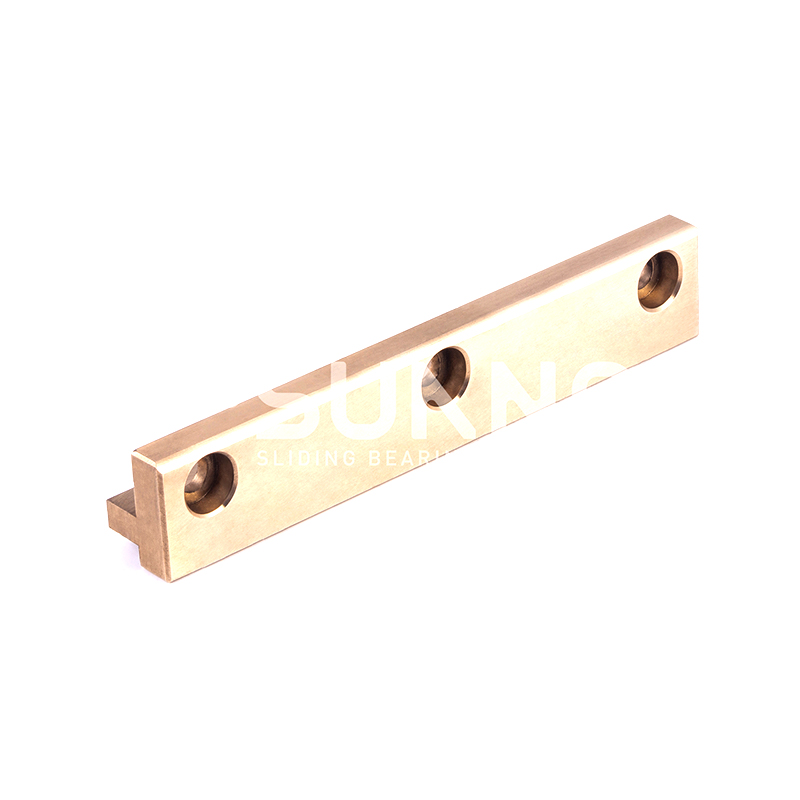

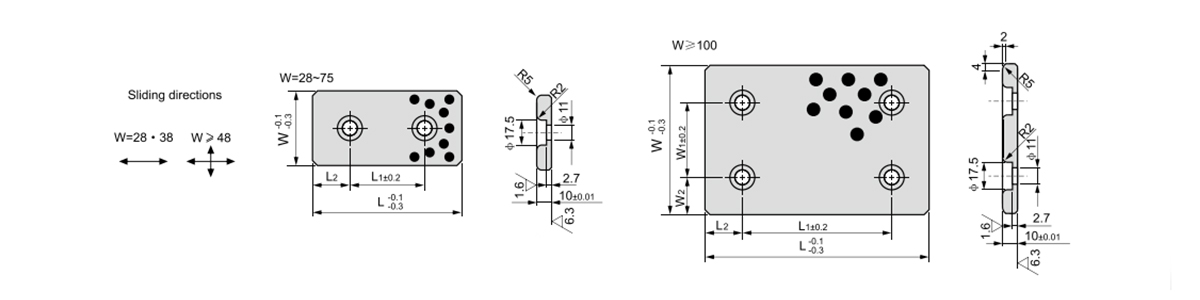

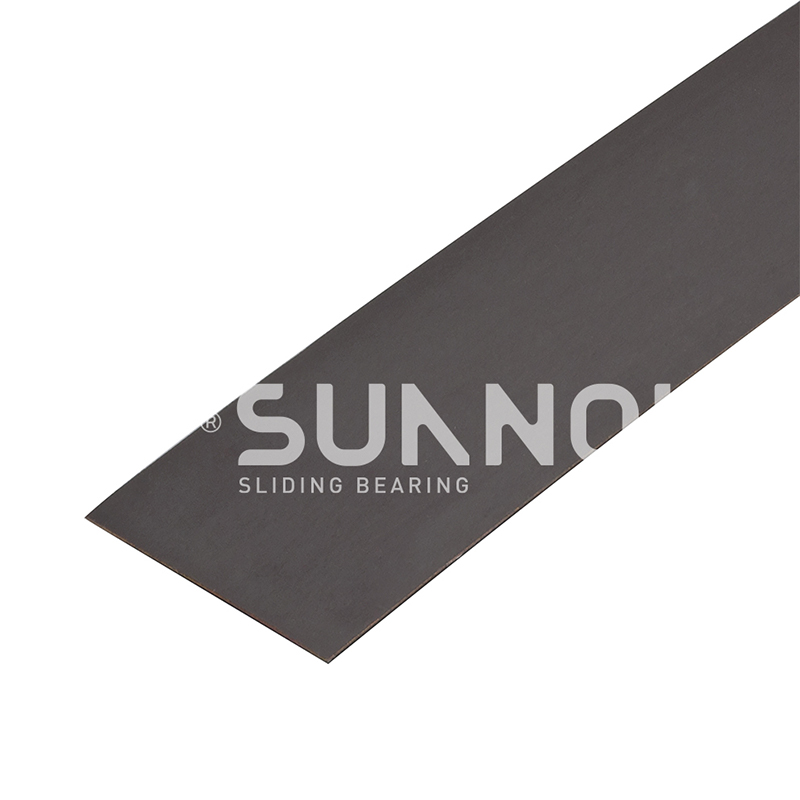

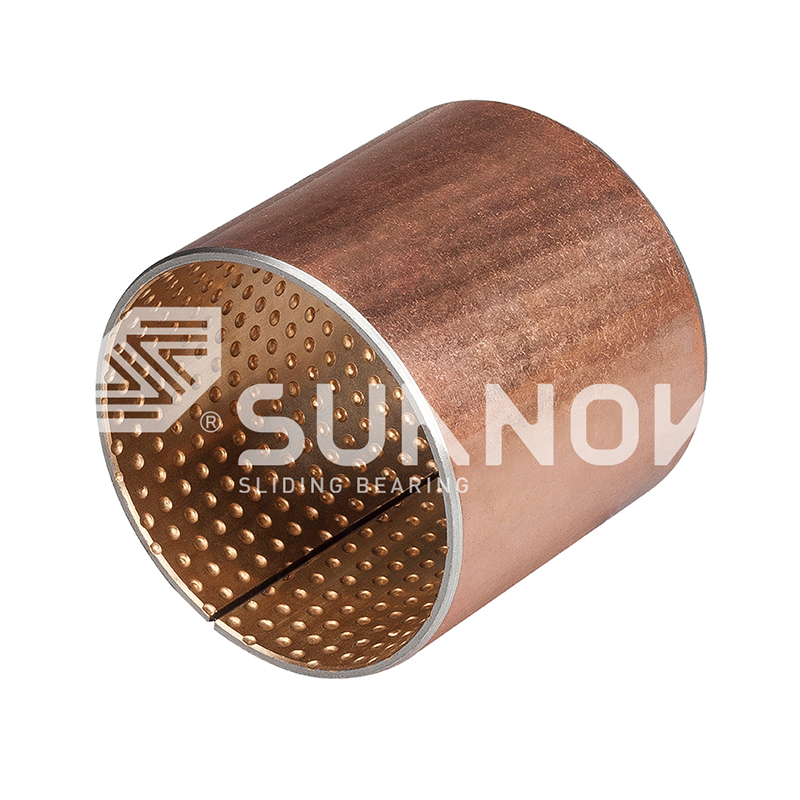

JSOL Embedded Bronze Oilless Wear Plate is a high-performance self-lubricating wear-resistant material designed for standard mechanical parts. Its core feature is to provide low friction, wear resistance and maintenance-free performance through the embedded bronze layer, which is suitable for high-load, low-speed or reciprocating motion scenarios. No external lubrication is required, which can reduce maintenance costs and extend equipment life.

Application areas:

Industrial machinery: used for injection molding machines, stamping machines, machine tool guides and other parts that require wear-resistant support.

Automation equipment: suitable for high-precision motion systems such as robot arm joints and linear slides.

Heavy equipment: such as the wear-resistant requirements of engineering machinery's hinge points, bearing bushings and other harsh working conditions.

FAQ 1: Does JSOL wear-resistant plate need to be lubricated regularly?

No. This product adopts a composite design of embedded bronze and self-lubricating materials. Lubricating particles are released through the bronze layer during operation to achieve oil-free lubrication. It is suitable for occasions where frequent maintenance is not possible or lubricating oil is contaminated, such as food machinery or clean workshop equipment.

FAQ 2: What loads and temperatures can this wear plate withstand?

Typical load capacity can reach 50-150MPa, depending on thickness and structural design; operating temperature range is -50℃ to +250℃. Suitable for medium and high pressure and normal to high temperature environments, but extreme conditions require coating or cooling system.

FAQ 3: What are the advantages of JSOL plate compared to other wear-resistant materials?

Compared with traditional nylon or metal plates, JSOL plate has the thermal conductivity and self-lubricity of bronze, low friction coefficient (0.05-0.15), low noise, and corrosion resistance. It is particularly suitable for automation or heavy equipment that requires long-term stable operation and reduced downtime maintenance.