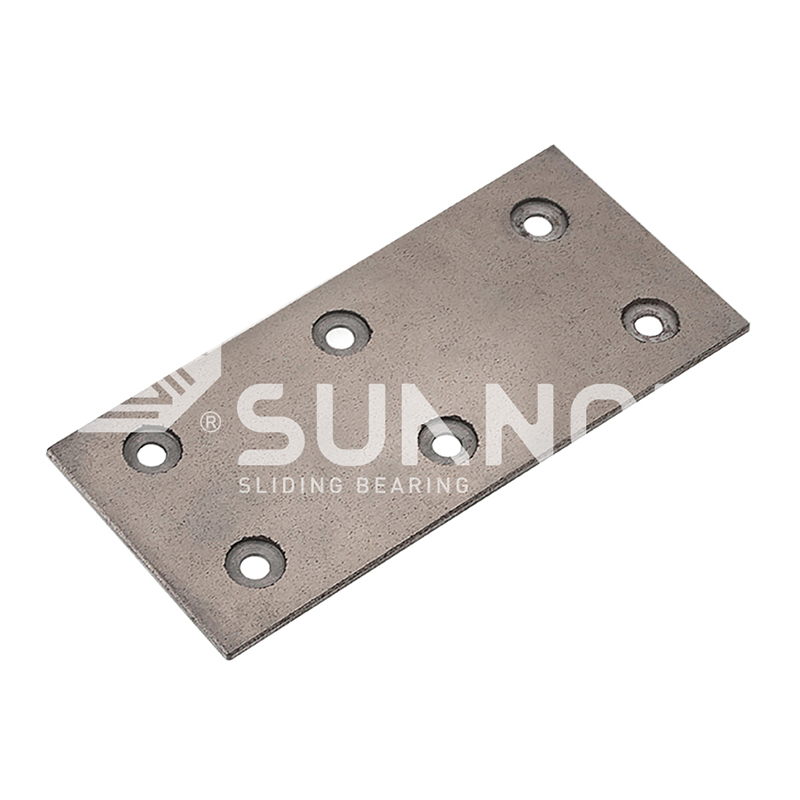

JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing is a high-performance self-lubricating bearing that uses solid lubricants embedded in a metal matrix and can operate for a long time without external oil supply. It has the characteristics of wear resistance, high temperature resistance, and corrosion resistance, and is suitable for high-load, low-speed or swing motion scenarios.

Application areas:

Industrial machinery-such as injection molding machines, stamping machine guides.

Automotive industry-suspension systems, steering components.

Aerospace-aircraft flaps, landing gear guide devices.

Energy equipment-wind turbine variable pitch systems, hydraulic mechanisms.

FAQ:

Q1: What are the advantages of JEFW bearings compared with traditional oil-lubricated bearings?

A1: JEFW bearings use solid lubrication technology, do not require oiling and maintenance, avoid oil leakage, and are suitable for environments with high cleaning requirements (such as food machinery). Its wear-resistant layer has a long life and can work at extreme temperatures of -200℃~300℃. It is more adaptable to harsh working conditions than traditional bearings, such as high-temperature kilns or low-temperature freezing equipment.

Q2: Is this bearing suitable for high-speed rotating equipment?

A2: It is not recommended for high-speed continuous rotation. JEFW bearings are designed for slow, heavy-loaded or swinging motion (such as joints of construction machinery), and their solid lubricating film performs better at low speeds. If high-speed applications are required, it is recommended to choose oil-containing bearings or composite lubrication solutions.

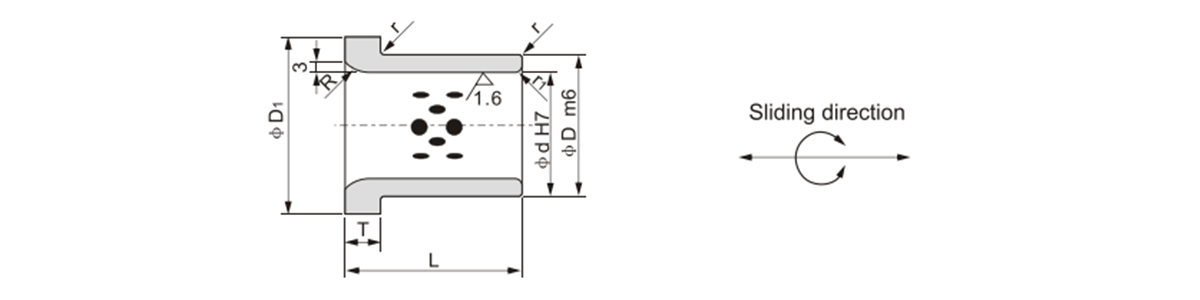

Q3: How to install and maintain JEFW flange bearings?

A3: During installation, ensure that the flange surface fits tightly with the base to avoid eccentric loading. Due to the self-lubricating properties, there is no need to add oil on a daily basis, but the surface dust needs to be removed regularly (compressed air purge). If used in a highly corrosive environment (such as an offshore platform), it is recommended to choose a stainless steel base model to extend life.