-

JDB Solid-lubricating Bearing High Temperature Brass JGB Oilless Ejector Guide Bearings

JDB Solid-lubricating Bearing High Temperature Brass JGB Oilless Ejector Guide Bearings -

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing -

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing -

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed)

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed) -

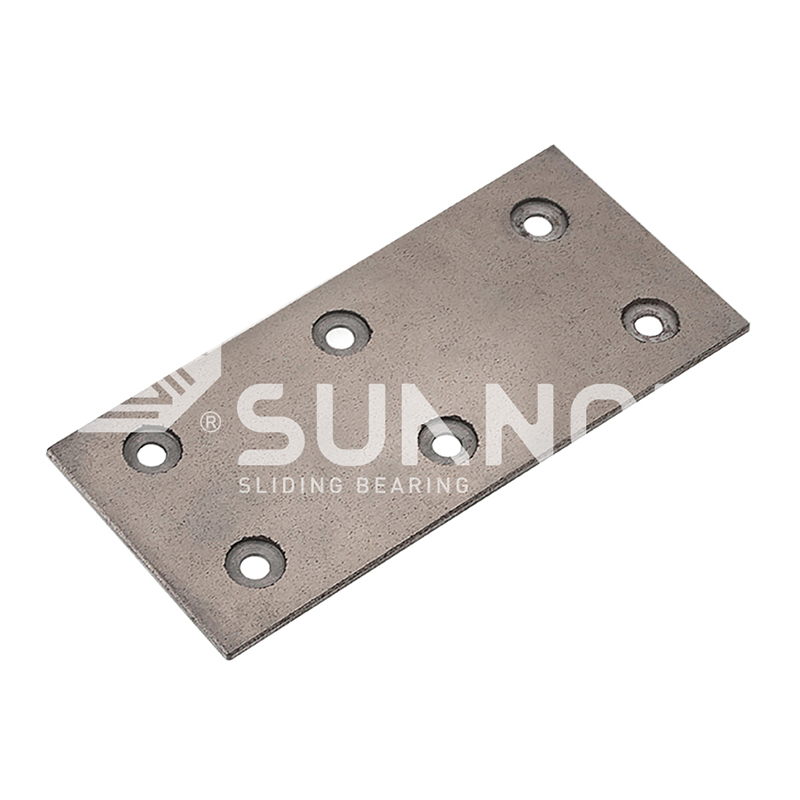

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface -

SF-2 Boundary Lubricating Bearing SF-2Y Boundary Self-lubricating Bearing - Low Friction Dry Lubricant Bushings for Industrial Machinery

SF-2 Boundary Lubricating Bearing SF-2Y Boundary Self-lubricating Bearing - Low Friction Dry Lubricant Bushings for Industrial Machinery -

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery -

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

Predicting Service Life and Wear Resistance of Oilless Bronze Bushing Under Extreme Operating Conditions

Industry News-- 1 I. The Criticality of Self-Lubrication in Industrial Bearings

- 2 II. The PV Factor: Load and Velocity Limits

- 3 III. Thermal Constraints and Material Degradation

- 4 IV. Analyzing Wear and Service Life Prediction

- 5 V. Quality Assurance and Customization for B2B Procurement

- 6 VI. Precision in Self-Lubricating Solutions

- 7 VII. Frequently Asked Questions (FAQs)

- 7.1 Q1: How does the PV factor relate to the expected lifespan of an oilless bronze bushing?

- 7.2 Q2: What is the main benefit of using a centrifugal cast bronze self lubricating bearing performance over a static cast one?

- 7.3 Q3: Which bronze alloy is recommended for minimizing high load oilless bronze bushing wear rates?

- 7.4 Q4: How does the oilless bronze bushing temperature impact on lifespan differ from a traditional lubricated bearing?

- 7.5 Q5: Why is the service life prediction for graphite plugged bronze inherently difficult?

I. The Criticality of Self-Lubrication in Industrial Bearings

In heavy machinery, construction equipment, and specialized industrial plants, reliable motion control often depends on bearings operating outside the parameters of traditional oil or grease lubrication. The oilless bronze bushing is the engineered solution for these challenging environments, relying on embedded solid lubricants (typically graphite or PTFE plugs) to ensure low friction and sustained performance under high loads, slow speeds, or extreme temperatures. Understanding the interplay between load, speed, and temperature is paramount for B2B procurement specialists and design engineers tasked with maximizing equipment uptime and minimizing maintenance cycles. Zhejiang Shuangnuo Bearing Technology Co., Ltd. specializes in producing a diverse range of self-lubricating copper alloy products. Our dedication to quality begins at the source: we insist on independent casting production of raw materials using advanced processes like centrifugal casting, continuous casting, and metal mold casting to ensure the quality of the brass, aluminum bronze, and tin bronze alloys. The entire production process, from material composition verification (three-time spectrometer testing) to integrated processing on over 80 sets of advanced CNC equipment, ensures product integrity and minimizes lead times. We adhere to a business philosophy of "moderation and harmony, integrity-based," committing to professional product application solutions and personalized, tailor-made design.

Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing

II. The PV Factor: Load and Velocity Limits

The most fundamental indicator for predicting the performance of an oilless bronze bushing is the Pressure-Velocity (PV) factor, which is the product of the contact pressure (P) on the projected bearing area and the surface sliding velocity (V). This parameter directly correlates with the heat generated at the bearing surface (friction power) and thus dictates the bearing's thermal stability and wear rate. Operating beyond the Limiting PV will rapidly break down the solid lubricant layer, leading to metal-on-metal contact and catastrophic failure.

A. Oilless Bronze Bushing PV Limit Assessment

The oilless bronze bushing PV limit assessment is essential for determining a bearing's suitability for an application. The Limiting PV is not a single value; it varies significantly between continuous and intermittent operation, as continuous operation allows less time for heat dissipation. Products like solid inlaid self-lubricating bearings, which benefit from the high thermal conductivity of the bronze base, often have a much higher Limiting PV than sintered bimetallic products in high-speed applications. Below is a comparative example of the limiting continuous PV factor for typical self-lubricating products:

| Bearing Type | Primary Lubrication Method | Typical Limiting PV (N/mm² * m/s) | Primary Application Focus |

|---|---|---|---|

| Solid Inlaid Bronze | Graphite Plugs | ~1.0 - 1.6 | High Load, Low Speed |

| Sintered Bimetallic Products | Porous Sintered Layer / Oil | ~3.0 - 4.5 | Medium Load, Medium/High Speed |

III. Thermal Constraints and Material Degradation

Temperature is a silent killer of bearing lifespan. Frictional heat generated from the PV factor, combined with high ambient operating temperatures, dictates the efficacy of the solid lubricant and the stability of the bronze substrate. Every copper alloy has a critical temperature threshold. Exceeding this limit causes the bronze matrix to soften and significantly accelerates wear.

A. Oilless Bronze Bushing Temperature Impact on Lifespan

The oilless bronze bushing temperature impact on lifespan is often tied to the oxidation and softening point of the bronze alloy. Tin bronze (e.g., CuSn12) offers better temperature stability and greater hardness than standard brass in elevated temperature environments. Furthermore, if the temperature is high enough, the solid lubricant (such as graphite) can oxidize or degrade, preventing the formation of the crucial transfer film on the mating surface, which is essential for self-lubrication. Therefore, the selection of the bronze base material is as critical as the lubricant selection for applications over 150 degrees Celsius.

IV. Analyzing Wear and Service Life Prediction

Predicting the service life of an oilless bronze bushing involves analyzing its wear rate, which is the slope of the wear depth over time. The lifespan ($L$) is often predicted using the formula $L = \frac{T}{K \cdot P \cdot V}$, where $T$ is the allowable wear depth and $K$ is the specific wear rate constant. The initial "running-in" phase is critical; a proper running-in establishes the solid lubricant film, drastically lowering the steady-state wear rate.

A. High Load Oilless Bronze Bushing Wear Rates

Under high static or dynamic loads, the high load oilless bronze bushing wear rates increase exponentially. The compressive stress placed on the bearing determines how effectively the solid lubricant can transfer to the mating shaft surface. If the load is too high, the lubricant plugs can be crushed or extruded before they can perform their function. Products made from robust aluminum bronze (e.g., CuAl10Ni5Fe4), manufactured with the quality assurance of Zhejiang Shuangnuo's proprietary casting, offer superior compressive strength and are preferred for severe high-load applications. The specific wear rate ($K$) varies significantly by base metal under high loads:

| Bronze Alloy Type | Primary Component Strength | Wear Rate Relative to Standard Brass | Recommended Operating Load (P) |

|---|---|---|---|

| Brass (CuZn Series) | Good | High (Lower wear life) | Low to Medium |

| Tin Bronze (CuSn Series) | Very Good | Medium | Medium to High |

| Aluminum Bronze (CuAlNiFe Series) | Excellent | Low (Longest wear life) | High to Very High |

B. Centrifugal Cast Bronze Self Lubricating Bearing Performance

The quality of the bronze base is foundational. Centrifugal cast bronze self lubricating bearing performance surpasses that of simple static castings due to the process creating a finer grain structure, reduced porosity, and higher material density. This enhanced microstructure improves the mechanical properties, providing a stronger, more wear-resistant base for the embedded lubricant plugs, thereby significantly contributing to a more accurate service life prediction for graphite plugged bronze. Our commitment to material composition monitoring and mechanical properties testing by national agencies ensures every batch meets the highest standards for durability and performance.

V. Quality Assurance and Customization for B2B Procurement

For B2B procurement, the ability to source complex, high-quality self-lubricating bearings with short lead times is vital. Zhejiang Shuangnuo Bearing Technology Co., Ltd. provides integrated production, from raw material casting to final CNC machining, ensuring control over the entire supply chain. Our focus is on providing professional product application solutions, including personalized, tailor-made design and customization based on customer product characteristics and application specifics. We provide customers with authoritative test reports to confirm material composition and mechanical properties, validating the technical specifications of our oilless bronze bushing products.

VI. Precision in Self-Lubricating Solutions

Maximizing the service life and wear resistance of an oilless bronze bushing is an exercise in engineering precision, dictated primarily by managing the Limiting PV and temperature. By selecting the correct bronze alloy and self-lubricating design—supported by the material quality and manufacturing expertise of a specialized producer like Zhejiang Shuangnuo—designers can accurately utilize oilless bronze bushing PV limit assessment data to ensure reliable, long-term performance, transforming high-maintenance applications into self-sufficient systems.

VII. Frequently Asked Questions (FAQs)

Q1: How does the PV factor relate to the expected lifespan of an oilless bronze bushing?

- A: The PV factor (Pressure x Velocity) is directly proportional to frictional heat generation. Operating above the Limiting PV accelerates the degradation of the solid lubricant film and the bronze matrix, leading to rapid, unpredictable wear and drastically reducing the expected lifespan.

Q2: What is the main benefit of using a centrifugal cast bronze self lubricating bearing performance over a static cast one?

- A: Centrifugal casting creates a denser, finer-grained microstructure in the bronze, which translates to superior mechanical strength, reduced porosity, and enhanced wear resistance. This foundational quality is critical for the long-term reliability of the self-lubricating bearing in high-stress applications.

Q3: Which bronze alloy is recommended for minimizing high load oilless bronze bushing wear rates?

- A: Aluminum bronze (e.g., CuAlNiFe series) is generally recommended for minimizing wear rates under high load conditions. It offers superior compressive strength and hardness compared to tin bronze or brass, allowing the bearing to withstand greater pressure without deformation or accelerated wear.

Q4: How does the oilless bronze bushing temperature impact on lifespan differ from a traditional lubricated bearing?

- A: While a traditional bearing risks lubricant breakdown at high temperatures, an oilless bronze bushing risks the oxidation or thermal decomposition of the *solid* lubricant (e.g., graphite) and the softening of the bronze matrix itself. Exceeding the material's critical temperature leads to failure due to material loss rather than fluid loss.

Q5: Why is the service life prediction for graphite plugged bronze inherently difficult?

- A: Service life prediction is difficult because the wear rate is highly dependent on environmental variables (dust, moisture) and the efficiency of the solid lubricant transfer film, which can vary with initial running-in quality and temperature fluctuations. It requires rigorous oilless bronze bushing PV limit assessment and temperature control to achieve accurate prediction.