-

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing -

JDB Solid-lubricating Bearing JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing

JDB Solid-lubricating Bearing JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing -

JDB Solid-lubricating Bearing JDB-5 Steel Embedded Wear Resistant Solid-lubricating Bearing

JDB Solid-lubricating Bearing JDB-5 Steel Embedded Wear Resistant Solid-lubricating Bearing -

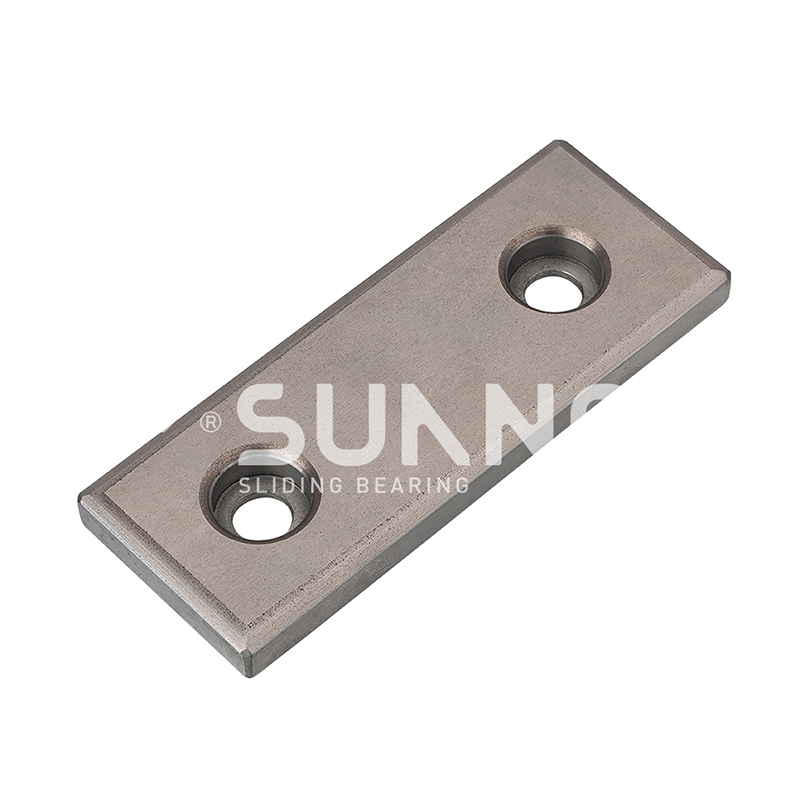

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications -

-

-

-

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing

Enhancing Performance of Oilless Bronze Bushing through Self-Lubrication and Maintenance Strategies

Industry News-- 0.1 1. Principles of Self-Lubrication

- 0.2 2. Comparison with Traditional Lubricated Bearings

- 0.3 3. Maintenance and Re-Lubrication Requirements

- 0.4 4. Material Selection and Load Capacity

- 0.5 5. Best Practices for Industrial Applications

- 1 FAQs

- 1.1 1. How does an oilless bronze bushing reduce friction compared to traditional bearings?

- 1.2 2. Are oilless bronze bushings completely maintenance-free?

- 1.3 3. What are the benefits of self-lubricating bronze bearings in industrial machines?

- 1.4 4. How to select material for high-load applications?

- 1.5 5. What inspection routines are recommended for oilless bronze bushings?

1. Principles of Self-Lubrication

Self-lubricating bronze bearing integrates solid lubricants such as graphite or PTFE into the bronze matrix. This reduces friction by forming a continuous lubricating film between the shaft and bearing surface.

| Bearing Type | Friction Coefficient | Lubrication Requirement | Load Capacity |

|---|---|---|---|

| Traditional bronze bearing | 0.08-0.12 | Requires regular oiling | Moderate |

| Oilless bronze bushing | 0.02-0.05 | Maintenance-free or minimal | High |

2. Comparison with Traditional Lubricated Bearings

Compared with traditional lubricated bearings, low-friction bronze bushing reduces downtime, eliminates contamination risk from lubricants, and lowers operational costs.

- Friction reduction improves efficiency and reduces energy consumption.

- Self-lubrication prevents overheating and wear during extended operation.

- Eliminates periodic relubrication schedules.

3. Maintenance and Re-Lubrication Requirements

Although maintenance-free bronze bushing is designed to operate without regular lubrication, periodic inspection is recommended under extreme load or temperature conditions:

| Condition | Recommended Action | Frequency |

|---|---|---|

| High-load operation | Visual inspection for wear and thermal degradation | Every 6-12 months |

| High-temperature environment | Check lubricant integrity in composite bushings | Every 3-6 months |

| Standard conditions | No additional lubrication required | As needed |

4. Material Selection and Load Capacity

High-load bronze sleeve and copper alloy oilless bearing materials must be selected based on operating load, speed, and environmental conditions. Considerations include:

- Embedding solid lubricants in a uniform distribution.

- Optimizing alloy composition for strength and wear resistance.

- Balancing cost with expected service life.

5. Best Practices for Industrial Applications

- Integrate self-lubricating bronze bearing into equipment designs to minimize maintenance intervals.

- Monitor temperature and wear in high-load applications.

- Use precision machining to ensure tight tolerances and optimal contact surfaces.

- Plan inspection schedules based on operational environment and load cycles.

- Choose appropriate alloy and composite configurations for specific industrial requirements.

FAQs

1. How does an oilless bronze bushing reduce friction compared to traditional bearings?

The embedded solid lubricants in oilless bronze bushing form a continuous lubrication film, reducing the friction coefficient from 0.08-0.12 in traditional bronze bearings to 0.02-0.05, leading to higher efficiency and lower wear.

2. Are oilless bronze bushings completely maintenance-free?

Under standard conditions, maintenance-free bronze bushing operates without additional lubrication. However, periodic inspection is advised for high-load or high-temperature environments to ensure longevity.

3. What are the benefits of self-lubricating bronze bearings in industrial machines?

Self-lubricating bronze bearing reduces downtime, eliminates contamination risk from lubricants, lowers operational costs, and extends service life, especially in harsh operating conditions.

4. How to select material for high-load applications?

High-load bronze sleeve or copper alloy oilless bearing materials should be chosen based on load, speed, and temperature. Uniform solid lubricant distribution and wear-resistant alloys are critical for performance.

5. What inspection routines are recommended for oilless bronze bushings?

Visual inspection every 6-12 months for high-load applications and every 3-6 months in high-temperature environments is recommended. Standard conditions typically do not require additional lubrication.