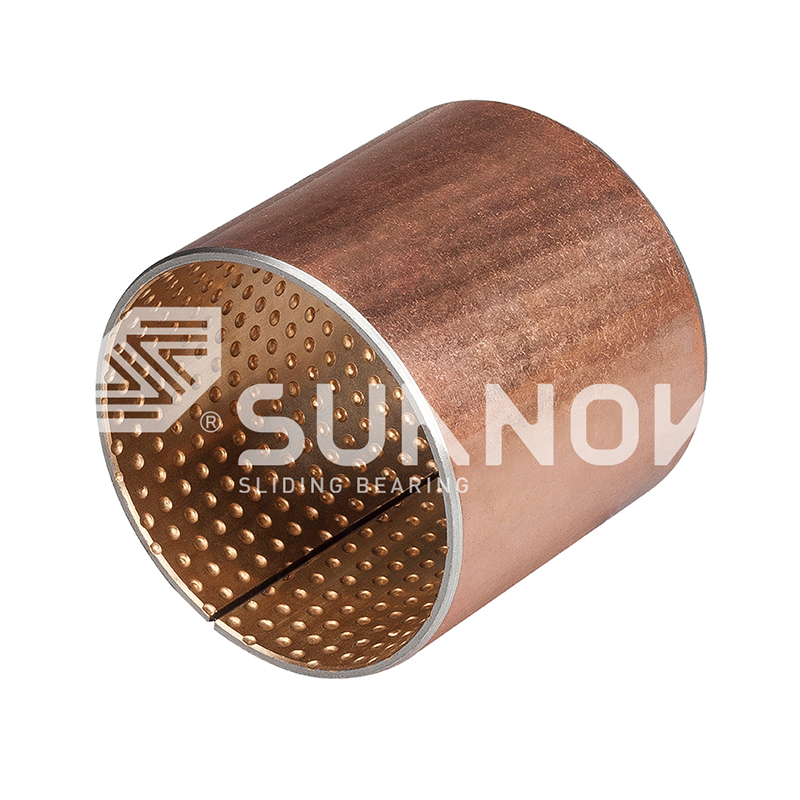

The JF-800 Bi-Metal Bearing is engineered for heavy-duty, low-speed sliding applications, offering superior durability and load capacity. Featuring a CuPb10Sn10 alloy surface, this bearing ensures excellent wear resistance and reduced friction, making it ideal for demanding industrial environments.

- Premium CuPb10Sn10 Alloy: High lead-tin bronze layer for enhanced wear resistance and low friction.

- Heavy-Duty Performance: Designed to withstand extreme loads in low-speed machinery.

- Long Service Life: Robust bi-metal construction reduces maintenance frequency.

- Wide Compatibility: Suitable for various industrial applications, including mining, construction, and marine equipment.

The JF-800 Bi-Metal Bearing is perfect for:

- Mining Equipment: Excavators, crushers, and conveyor systems.

- Construction Machinery: Cranes, bulldozers, and hydraulic presses.

- Marine & Offshore: Ship rudders, winches, and deck machinery.

- Industrial Gearboxes: Low-speed, high-load transmission systems.

Why Choose JF-800 Bi-Metal Bearing?

Our bi-metal sliding bearings are manufactured with precision to ensure optimal performance in harsh conditions. The CuPb10Sn10 alloy provides superior anti-friction properties, while the steel backing offers structural strength. This combination delivers long-lasting reliability for your heavy-duty applications.

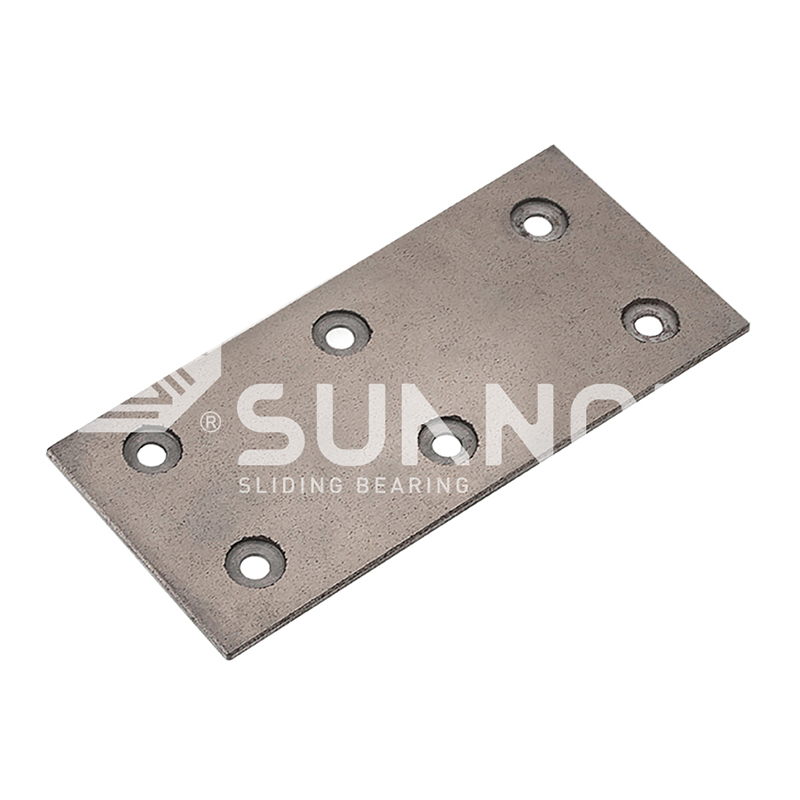

Custom Solutions Available

We offer customized bi-metal bearings tailored to your specific requirements, including size adjustments and material enhancements. Contact us today to discuss your needs!