-

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing -

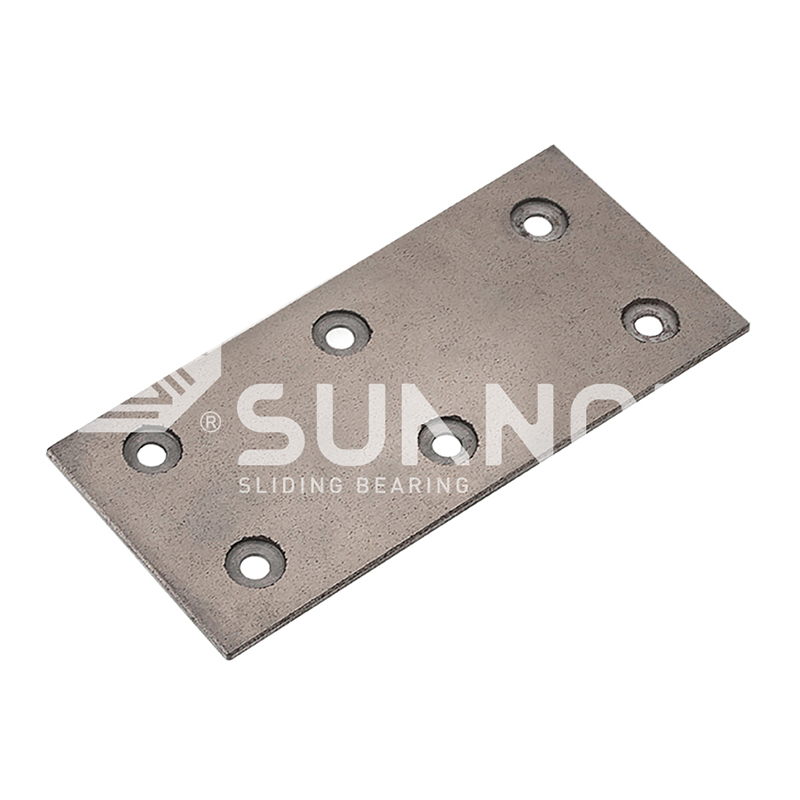

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface -

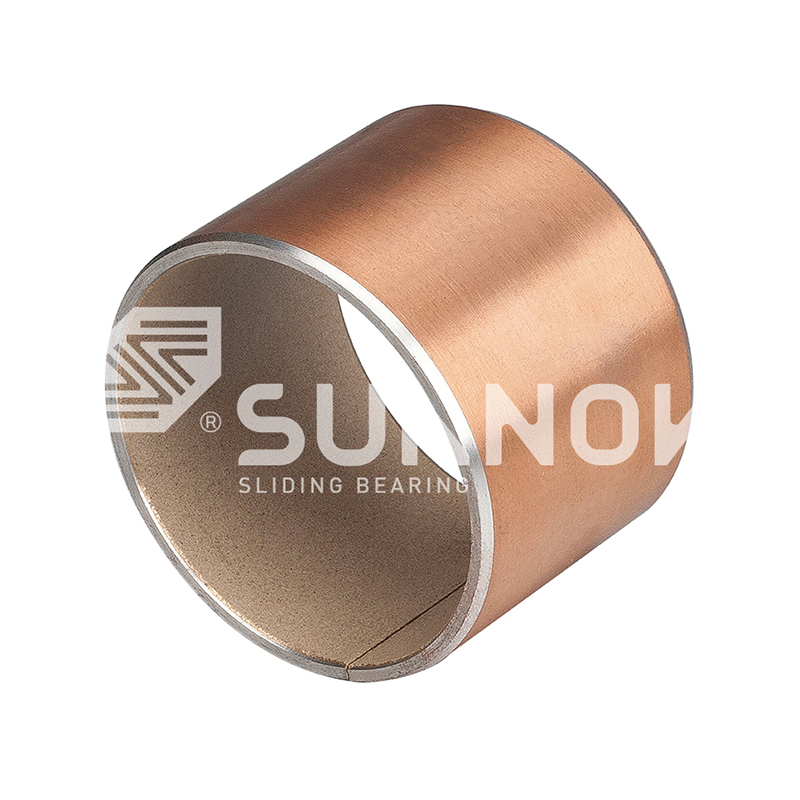

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

-

-

-

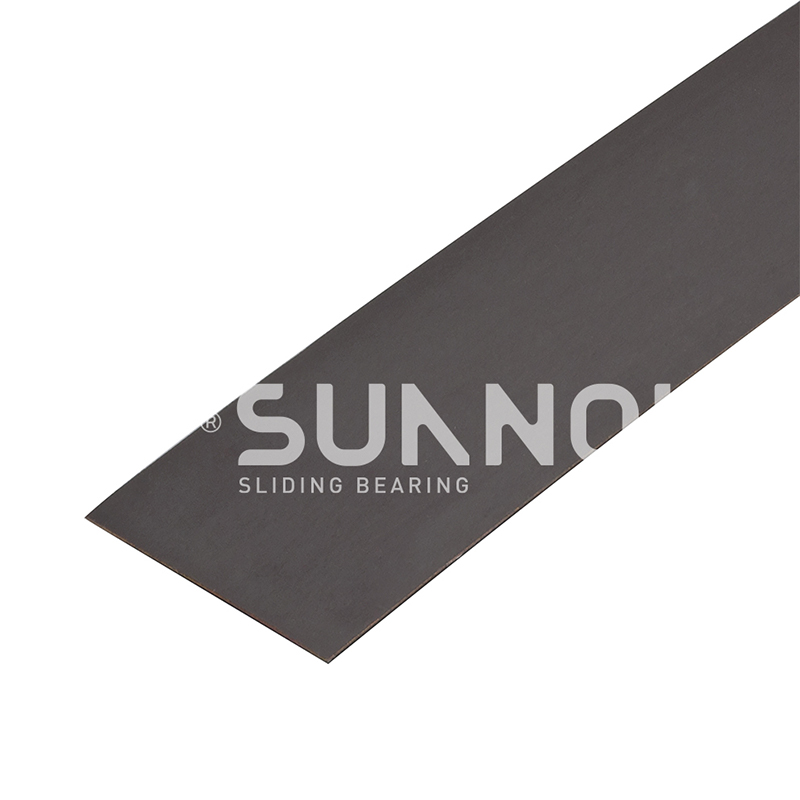

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip -

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush

Beyond Self-Lubrication: Defining the Performance Limits of Lubricating Bronze Bushings

Industry News-- 1 The Foundation of Self-Lubrication: Porous Bronze Technology

- 2 The Critical Metric: Assessing the PV Limit

- 3 The Upgrade Imperative: When to upgrade from porous to externally lubricated bronze

- 4 High-Demand Environments and Material Selection

- 5 Zhejiang Shuangnuo Bearing Technology Co., Ltd.: Expertise in Self-Lubricating Solutions

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. What is the PV limit and why is it crucial for oil-impregnated lubricating bronze bushings?

- 6.2 2. What primarily determines the Service life of self-lubricating bronze bearings?

- 6.3 3. When should an engineer decide When to upgrade from porous to externally lubricated bronze?

- 6.4 4. How does the PV limit calculation for oil-impregnated bronze bushings help in selection?

- 6.5 5. What material alternatives are suitable when Selecting bronze bushing lubrication for high-temperature applications?

Bronze bushings are foundational components in countless mechanical assemblies. While conventional solid bronze requires continuous external lubrication, oil-impregnated (sintered) bronze bushings offer maintenance-free operation through inherent self-lubrication. However, engineers must recognize the finite operational limits of these self-lubricating systems, particularly concerning their Pressure-Velocity (PV) limit and thermal stability. Precision engineering is required to identify the threshold where external lubrication becomes mandatory, thereby maximizing the **lubricating bronze bushings** lifespan and reliability.

JEGB/JEGBK Oiless Ejector Guide Bushing Oilless Ejector Bearing

The Foundation of Self-Lubrication: Porous Bronze Technology

Self-lubricating bronze bushings achieve their maintenance-free status through a unique manufacturing process.

Understanding Porosity and Oil Impregnation in Sintered Bronze

- Sintered bronze is manufactured by pressing and heating bronze powder, resulting in a porous matrix with an interconnected network of voids (typically 18% to 30% by volume).

- These pores are vacuum-filled with high-quality lubricating oil. During operation, the heat generated by friction causes the oil to expand and flow out of the pores onto the bearing surface. When the shaft stops, the oil retracts back into the pores, ready for the next cycle.

Determining the Service life of self-lubricating bronze bearings

The Service life of self-lubricating bronze bearings is primarily determined by the longevity of the initial oil charge. Factors that limit this life include continuous high temperature (which causes oil oxidation and degradation) and excessive PV loading (which accelerates oil depletion). Once the oil is depleted or degraded, the bushing transitions to a boundary lubrication regime, leading to rapid wear and failure.

The Critical Metric: Assessing the PV Limit

The Pressure-Velocity (PV) factor is the most important parameter for determining the continuous operating boundary of a bronze bushing.

PV limit calculation for oil-impregnated bronze bushings (Pressure x Velocity)

- **PV Factor:** Calculated as the bearing load pressure (P, Newtons per square millimeter or psi) multiplied by the sliding velocity (V, meters per second or fpm). This factor is proportional to the frictional heat generated within the bushing.

- **Limit Application:** For a typical self-lubricating bronze bushing, the **PV limit calculation for oil-impregnated bronze bushings** usually yields a limit significantly lower than that of externally lubricated solid bronze. Exceeding this limit causes excessive heat, thermal degradation of the oil, and premature wear.

Thermal Management and the PV Constraint

The maximum permissible PV value is fundamentally a thermal limit. If the heat generated exceeds the rate at which the bearing assembly can dissipate it, the operating temperature will rise until the internal oil breaks down, rapidly ending the Service life of self-lubricating bronze bearings.

The Upgrade Imperative: When to upgrade from porous to externally lubricated bronze

Engineers face a fundamental decision: rely on the convenience of self-lubrication or transition to forced lubrication for enhanced performance.

Decision Criteria: High Speed, High Load, and Temperature Excursions

- The decision of When to upgrade from porous to externally lubricated bronze is typically triggered when the operating PV value exceeds the thermal limit of the porous material or when the ambient/operating temperature exceeds 100 degrees Celsius, at which point oil oxidation accelerates rapidly.

Comparison of sintered and solid bronze bearing performance

While sintered bronze is ideal for low-to-moderate loads and intermittent operation, solid bronze (requiring external **lubricating bronze bushings**) provides a robust, high-performance solution. Solid bronze can handle significantly higher PV values because the continuous supply of fresh, cool lubricant flushes away heat and separates the surfaces under hydrodynamic conditions. This comparison is central to understanding the limitations of the self-lubricating design.

Sintered vs. Solid Bronze Application Limits Table

| Feature | Sintered Bronze (Self-Lubricating) | Solid Bronze (Externally Lubricated) |

|---|---|---|

| Lubrication Method | Internal Oil Impregnation (Finite life) | External Pump/Grease Fitting (Continuous supply) |

| PV Limit | Moderate (Limited by heat dissipation) | High (Limited by material strength) |

| Temperature Limit | Lower (Oil oxidation risk) | Higher (Lubricant dependent) |

High-Demand Environments and Material Selection

For applications where even externally lubricated solid bronze is challenged by extreme heat or specialized conditions, material selection must be further refined.

Selecting bronze bushing lubrication for high-temperature applications

- For environments requiring Selecting bronze bushing lubrication for high-temperature applications, the lubricating material must resist thermal degradation. This often means switching from mineral oil to synthetic lubricants or utilizing solid lubricants (like graphite or PTFE) embedded within the bronze alloy itself.

Alternative Solutions: Solid Inlaid and Bimetallic Bearings

When high PV values meet high temperature, integrated solutions like solid inlaid self-lubricating bearings (where graphite plugs provide continuous transfer film) or bimetallic bearings (offering a wear-resistant bronze layer on a steel backing for strength) overcome the thermal limits and finite life challenges faced by traditional sintered bronze.

Zhejiang Shuangnuo Bearing Technology Co., Ltd.: Expertise in Self-Lubricating Solutions

Zhejiang Shuangnuo Bearing Technology Co., Ltd. specializes in manufacturing various self-lubricating copper alloy products, utilizing advanced processes like centrifugal casting and sintering technology. We insist on independent casting production of raw materials, ensuring product quality from the source, and rigorously testing material composition three times using a spectrometer. Our integrated production capability, supported by over 80 sets of advanced CNC equipment, ensures short production cycles and guaranteed material quality. We focus on research, development, and production of new self-lubricating bearings, providing expert guidance on critical parameters like PV limit calculation for oil-impregnated bronze bushings and determining the precise Service life of self-lubricating bronze bearings. We help customers precisely identify When to upgrade from porous to externally lubricated bronze and offer tailored solutions, including solid inlaid and bimetallic bearings, making us a new star in the self-lubricating bearing industry.

Frequently Asked Questions (FAQ)

1. What is the PV limit and why is it crucial for oil-impregnated lubricating bronze bushings?

The PV limit (Pressure multiplied by Velocity) is proportional to the heat generated by friction. It is crucial because exceeding this limit leads to excessive temperature, causing the internal oil to degrade and accelerating the end of the bushing's effective life.

2. What primarily determines the Service life of self-lubricating bronze bearings?

The service life is primarily determined by the volume and longevity of the oil initially impregnated in the bronze pores. High temperatures and high PV loads accelerate the oxidation and depletion of this oil.

3. When should an engineer decide When to upgrade from porous to externally lubricated bronze?

The upgrade is typically necessary when the required operating PV factor or the continuous operating temperature exceeds the recommended thermal and load limits of the porous sintered material, generally around 100 degrees Celsius.

4. How does the PV limit calculation for oil-impregnated bronze bushings help in selection?

The calculation provides a single number that encapsulates the combined stress on the bushing. By comparing the calculated operational PV value to the material's permissible PV limit, engineers can quickly determine if the self-lubricating bushing is suitable for the application.

5. What material alternatives are suitable when Selecting bronze bushing lubrication for high-temperature applications?

For high-temperature applications, alternatives include solid inlaid self-lubricating bronze (with graphite plugs) or the use of externally supplied high-temperature synthetic lubricants with solid bronze, as conventional oil can quickly oxidize.