-

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings -

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing -

-

-

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers -

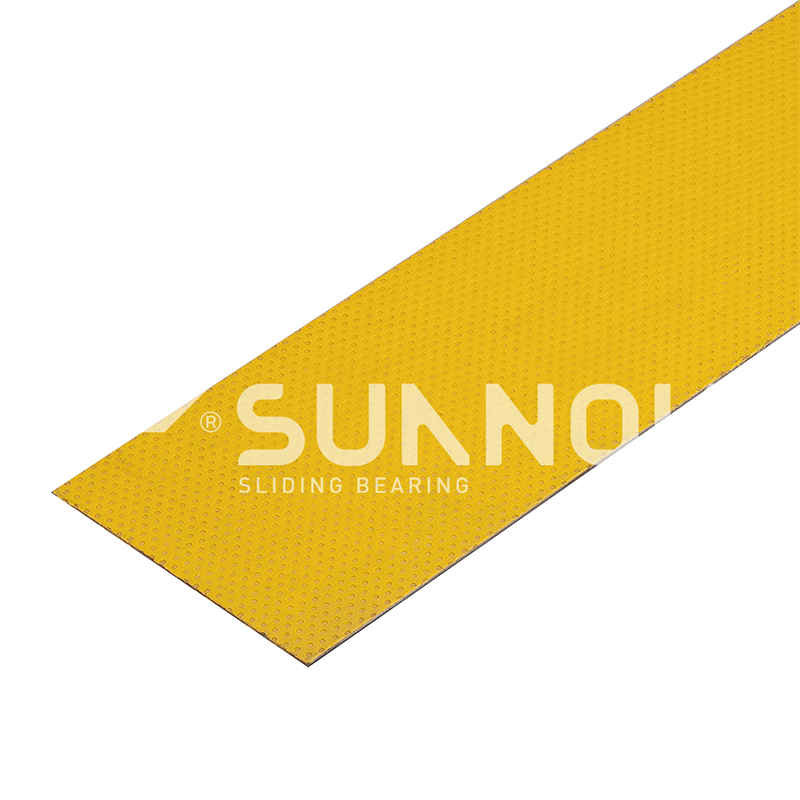

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE -

FB090 Bronze Wrapped Bearing FB091 High-Performance Copper Wrapped Bearing & Bushing | Bronze Bush

FB090 Bronze Wrapped Bearing FB091 High-Performance Copper Wrapped Bearing & Bushing | Bronze Bush -

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

Solid-Lubricating Bronze Bearings: A Guide to Performance and Selection

Industry News-- 1 What Are Solid-Lubricating Bronze Bearings?

- 2 Key Advantages of Using Solid-Lubricating Bronze Bearings

- 3

- 4 How to Choose the Right Solid-Lubricating Bronze Bearing

- 5 Common Applications and Industries

- 6 Maintenance and Service Life Expectations

- 7 FAQ

- 7.1 What is the maximum temperature a solid-lubricating bronze bearing can handle?

- 7.2 Can solid-lubricating bronze bearings be used in food-grade applications?

- 7.3 How do I calculate the PV value for my application?

- 7.4 What are the differences between graphite and PTFE as solid lubricants in these bearings?

- 7.5 Are there any disadvantages to using solid-lubricating bronze bearings?

In the world of machinery and motion, bearings are the unsung heroes, and among them, the Solid-Lubricating Bronze Bearing stands out for its unique combination of durability, self-lubrication, and reliability. These bearings are engineered to operate in demanding conditions where conventional oil or grease lubrication is impractical. This comprehensive guide delves deep into the mechanics, advantages, and optimal applications of solid-lubricating bronze bearings, providing you with the knowledge to make an informed selection for your engineering projects.

What Are Solid-Lubricating Bronze Bearings?

Solid-lubricating bronze bearings, often referred to as self-lubricating bushings, are components made from a bronze alloy matrix that has solid lubricants, such as graphite or PTFE, embedded within its structure. This design allows for a continuous, low-friction film to be transferred to the mating shaft surface during operation, eliminating the need for an external lubrication system. The base bronze material provides excellent load-bearing capacity and thermal conductivity, while the solid lubricants ensure smooth operation from startup to shutdown.

- Matrix Material: Typically a high-strength copper-tin bronze alloy, sometimes with added lead for enhanced machinability and seizure resistance.

- Solid Lubricants: Common lubricants include graphite, molybdenum disulfide (MoS2), and PTFE, each offering different benefits in terms of friction coefficient and temperature resistance.

- Operating Principle: As the bearing operates, friction-generated heat causes the solid lubricants to migrate to the bearing surface, creating a protective, low-friction film.

Key Advantages of Using Solid-Lubricating Bronze Bearings

The primary benefit of these bearings is their ability to function without an external oil or grease supply, which opens up a wide range of applications. This self-sufficiency leads to several key advantages that make them a preferred choice in many industries.

- Maintenance-Free Operation: They drastically reduce or eliminate the need for re-lubrication, lowering long-term maintenance costs and downtime.

- Excellent Performance in Harsh Environments: They are ideal for applications exposed to extreme temperatures, vacuum, high radiation, or where lubricants could be washed away by water or solvents.

- High Load Capacity: The bronze matrix can withstand significant static and dynamic loads, making them suitable for heavy machinery.

- Corrosion Resistance: Bronze alloys offer good resistance to corrosion, further enhancing their longevity in challenging environments.

Comparing Solid-Lubricating Bearings to Other Types

To understand where Solid-Lubricating Bronze Bearings fit best, it's helpful to compare them with other common bearing types. The choice often comes down to the specific operational requirements, such as speed, load, and environmental constraints.

The following table provides a clear comparison to aid in the selection process:

| Bearing Type | Lubrication Requirement | Typical Load Capacity | Ideal For |

| Solid-Lubricating Bronze | Self-lubricating / Maintenance-free | Very High | Harsh environments, high-load, low-speed applications |

| Oil-Impregnated Sintered Bronze | Self-lubricating but finite oil supply | Medium to High | General industrial applications with moderate loads and speeds |

| Roller Element Bearings | Requires continuous grease or oil lubrication | High (for dynamic loads) | High-speed, precision applications |

| Plastic Polymer Bearings | Often self-lubricating | Low to Medium | Corrosive environments, very low friction, lightweight designs |

Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing

How to Choose the Right Solid-Lubricating Bronze Bearing

Selecting the correct bearing is critical for optimal performance and service life. The process of selecting solid lubricating bronze bearings involves evaluating several key application parameters to ensure a perfect match.

- Load (PV Value): Calculate the bearing's pressure (P) multiplied by velocity (V). The bearing's PV rating must exceed the application's calculated PV value.

- Operating Temperature: Ensure the bearing material and lubricant are rated for your application's minimum and maximum temperatures.

- Shaft Material and Hardness: A harder shaft material is generally recommended to minimize wear on both the shaft and the bearing.

- Environmental Factors: Consider exposure to chemicals, moisture, dust, or other contaminants that could affect performance.

Understanding PV Value and Its Importance

The PV value is the most critical parameter in solid lubricating bronze bearing selection. It is a product of the bearing's load pressure (P in psi) and its surface speed (V in ft/min). Exceeding the maximum recommended PV value will lead to rapid wear and premature failure.

- Pressure (P): Calculated as the total load divided by the projected bearing area (Length x Inner Diameter).

- Velocity (V): The surface speed of the shaft against the bearing.

- Practical Consideration: Always include a safety factor when calculating your application's PV value to account for startup conditions and potential overloads.

Common Applications and Industries

The unique properties of Solid-Lubricating Bronze Bearings make them indispensable across a wide spectrum of industries. Their robustness and maintenance-free nature are highly valued in applications where reliability is paramount.

- Automotive and Transportation: Used in suspension systems, brake components, and kingpins, where they provide reliable performance for high-load bronze bushings.

- Construction and Agriculture: Ideal for heavy equipment like excavators, tractors, and loaders, operating in dirty, high-shock load environments.

- Industrial Machinery: Found in steel mills, conveyor systems, and hydraulic machinery, often in high-temperature areas.

- Aerospace and Marine: Used in control surfaces, landing gear, and rudder assemblies due to their reliability in extreme conditions and resistance to corrosion.

Maintenance and Service Life Expectations

While these bearings are designed to be maintenance-free, understanding the factors that influence their service life is crucial for predictive maintenance and system reliability. The longevity of self-lubricating bronze bearings is primarily determined by wear, which is a function of load, speed, alignment, and environmental conditions.

- Wear Mechanisms: Normal wear occurs as the solid lubricant is slowly consumed. Abnormal wear can be caused by misalignment, contamination, or operation beyond the PV limit.

- Predicting Service Life: Life can be estimated based on wear rate data provided by manufacturers, which is typically given as wear depth per unit of time or distance traveled under specific PV conditions.

- Inspection Tips: During routine maintenance, check for excessive play, unusual noise, or visible wear. The bearing should be replaced if the wall thickness has worn down beyond the manufacturer's recommended limit.

Tips for Maximizing Bearing Life

To ensure you get the maximum longevity from your self-lubricating bronze bearings, follow these best practices during installation and operation.

- Proper Installation: Use the correct tools (arbor press) to press-fit the bearing, ensuring it is square to the housing to avoid brinelling or damage.

- Adequate Clearance: Maintain the proper radial clearance between the bearing ID and the shaft OD as specified by the manufacturer.

- Shaft Finish: A smooth, hard shaft surface with the correct surface finish will significantly reduce wear rates.

- Cleanliness: Keep the bearing and shaft area clean from abrasive contaminants to prevent accelerated wear.

FAQ

What is the maximum temperature a solid-lubricating bronze bearing can handle?

The maximum operating temperature depends on the specific bronze alloy and the type of solid lubricant used. Standard graphite-based bearings can typically operate continuously up to 350°C (662°F), while some special formulations can handle even higher temperatures. PTFE-based lubricants have a lower maximum, usually around 250°C (482°F). It is crucial to consult the manufacturer's datasheet for the exact temperature ratings of the specific bearing you are using, as exceeding these limits can degrade the lubricant and the bronze matrix, leading to failure.

Can solid-lubricating bronze bearings be used in food-grade applications?

Yes, but with careful selection. Standard bronze bearings with graphite may not be suitable for direct food contact. However, manufacturers offer food-grade versions that use approved solid lubricants like PTFE or special food-grade graphite and are made from specific, non-toxic bronze alloys that comply with FDA or other international food safety standards. It is essential to specify "food-grade" or "FDA-compliant" when selecting a bearing for such applications to avoid contamination.

How do I calculate the PV value for my application?

Calculating the PV value is a two-step process. First, calculate the bearing pressure (P) in psi: P = Load (lbs) / [Bearing ID (in) x Bearing Length (in)]. Second, calculate the velocity (V) in surface feet per minute (sfpm): V = (π x Shaft Diameter (in) x RPM) / 12. Finally, multiply P and V to get the PV value in psi x sfpm. Compare this value to the maximum PV rating provided by the bearing manufacturer. Always include a safety factor (e.g., 20-50%) to account for startup transients and unexpected load variations.

What are the differences between graphite and PTFE as solid lubricants in these bearings?

Graphite and PTFE are the two most common solid lubricants, each with distinct properties. Graphite offers excellent thermal stability, high-temperature performance, and good electrical conductivity. PTFE (Teflon) has an extremely low coefficient of friction and is chemically inert, but it has a lower maximum service temperature and can cold-flow under very high loads. The choice often involves a trade-off between the need for low friction (favoring PTFE) and the need for high-temperature stability (favoring graphite). Some advanced bearings even use a combination of both to leverage the benefits of each.

Are there any disadvantages to using solid-lubricating bronze bearings?

While highly advantageous in many scenarios, they are not a universal solution. The primary disadvantages include a lower maximum speed capability compared to roller bearings, as high speeds can generate excessive heat. They also generally have a higher coefficient of friction than hydrodynamically lubricated journal bearings. Furthermore, the initial cost can be higher than standard plain bearings, though this is often offset by the savings in maintenance and eliminated lubrication systems over the bearing's lifetime.