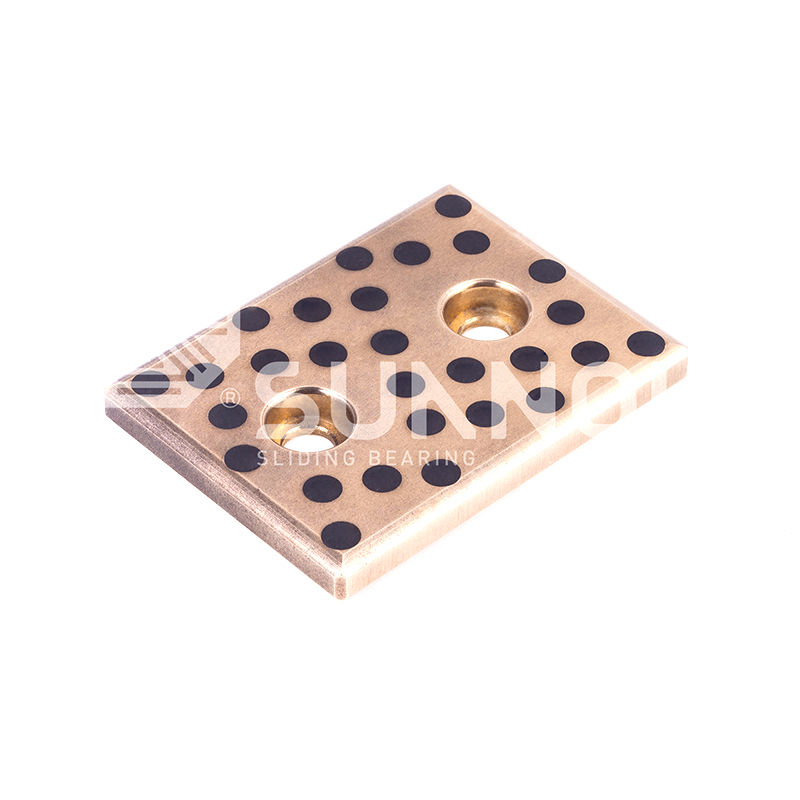

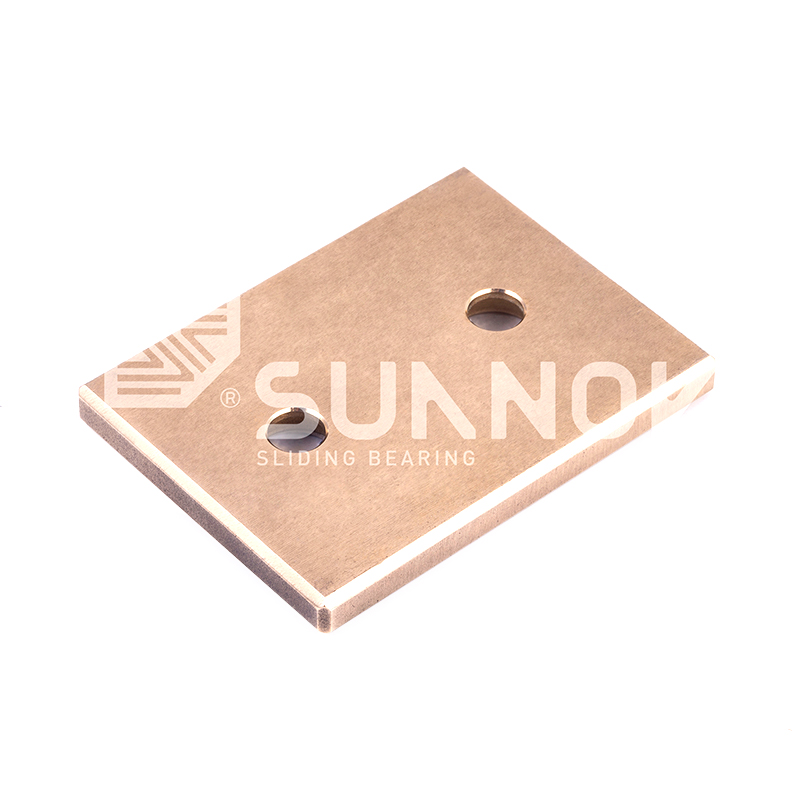

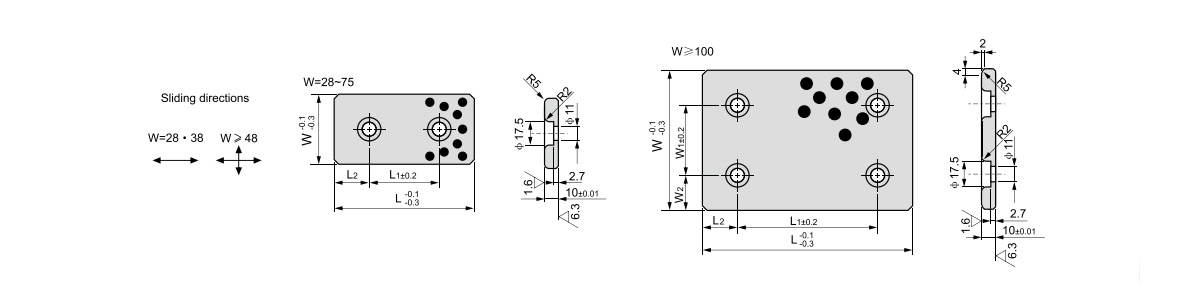

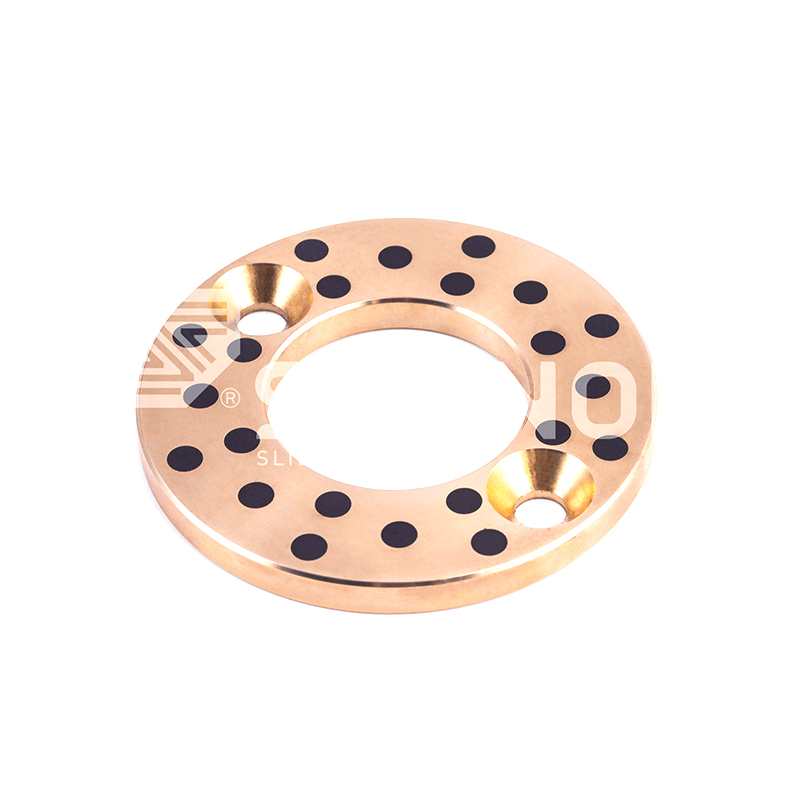

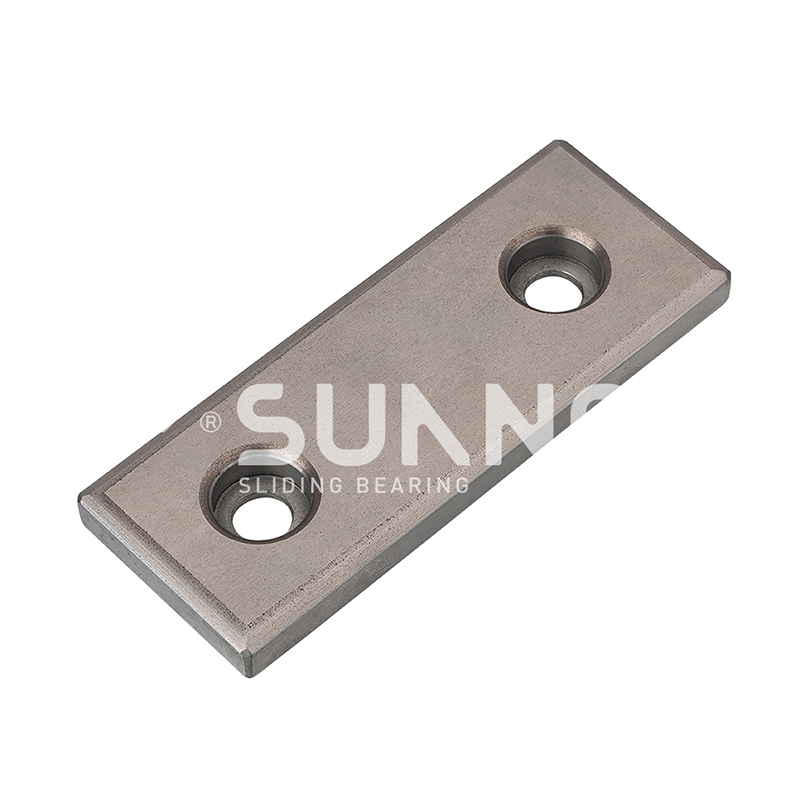

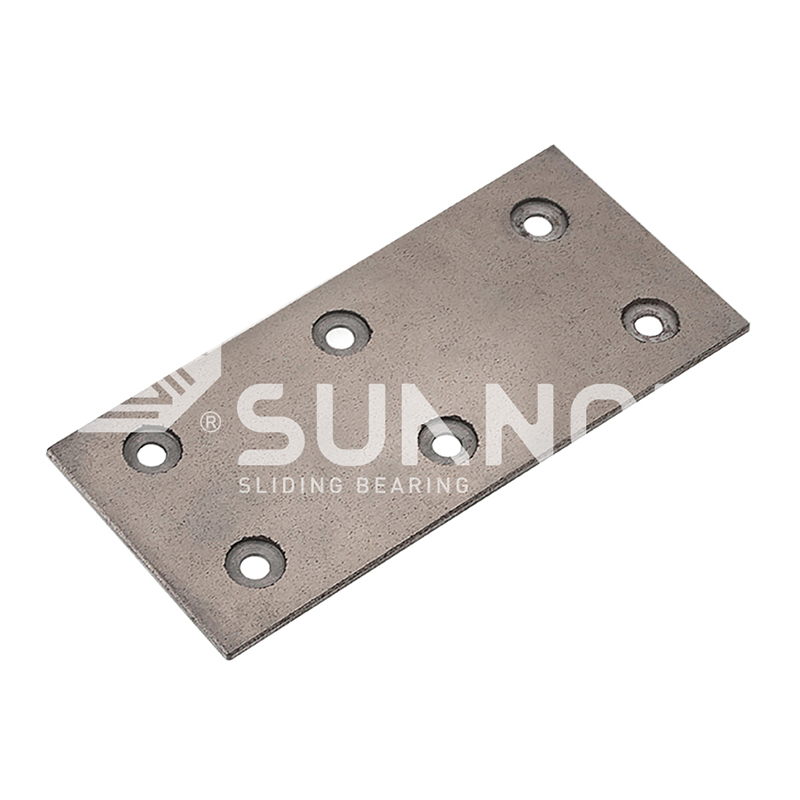

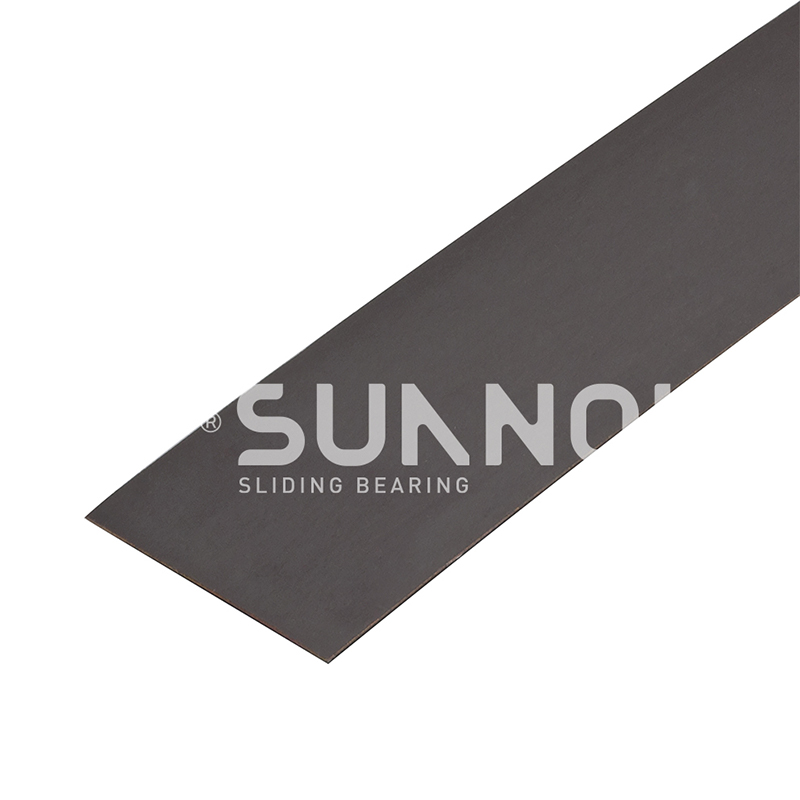

JTWP No Oil Needed Wear Resistance Zero Maintenance Oilless Wear Plate is a high-performance self-lubricating wear-resistant material that can operate for a long time under harsh working conditions without external lubrication. It uses special composite materials or metal-based embedded solid lubricant technology, has extremely low friction coefficient, high wear resistance and impact resistance, and is suitable for mechanical scenes with high load, low speed or frequent start and stop, significantly reducing maintenance costs and downtime.

Application areas:

Heavy industrial equipment: such as guide liners and sliders of metallurgical rolling mills and mining machinery.

Engineering machinery: spherical bearings and bucket liners of excavators and loaders.

Automated production lines: friction parts that require maintenance-free, such as conveyor chain plates and guide rails.

Ships and port machinery: corrosion-resistant and salt spray-resistant environments such as deck machinery and crane hinges.

FAQ:

Q1: Why choose oil-free wear-resistant liners instead of traditional lubricated liners?

A1: Traditional liners require regular oiling and maintenance, and are prone to wear due to insufficient lubrication. The oil-free liner is embedded in the material with solid lubricants, which is oil-free for life and reduces maintenance frequency by more than 50%. It is especially suitable for dusty, oil-sensitive (such as food, medicine) or extreme temperature environments, and has a lower overall cost.

Q2: Can the product maintain its performance in high temperature environments?

A2: Yes. The use of high-temperature stable composite materials (such as PTFE/metal matrix) can work stably under -200℃ to +280℃ conditions, and the friction coefficient fluctuates by less than 10%. Some models can even withstand short-term high temperatures of 500℃, which is suitable for steel plants or boiler equipment.

Q3: How to ensure the life of the oil-free liner under heavy load conditions?

A3: Through the composite design of high-hardness matrix (such as steel back) and self-lubricating layer, the dynamic load can reach more than 150MPa. Actual measured data shows that in mining crushers, the life is 3-5 times longer than that of ordinary liner, and after wear, it can be repaired by replacing local modules, further reducing costs.