-

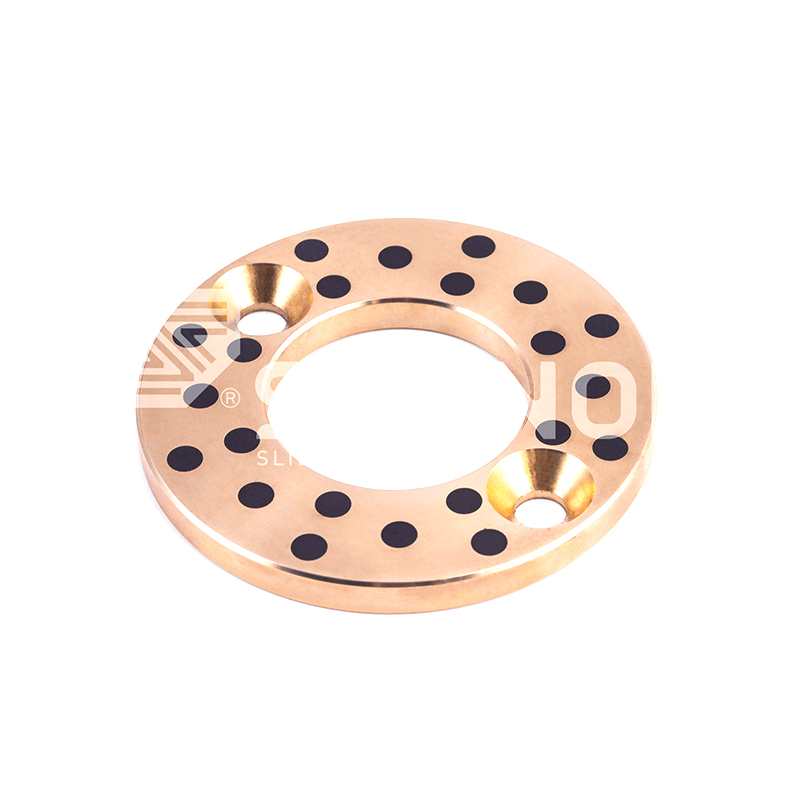

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing -

JDB Solid-lubricating Bearing High Temperature Brass JGB Oilless Ejector Guide Bearings

JDB Solid-lubricating Bearing High Temperature Brass JGB Oilless Ejector Guide Bearings -

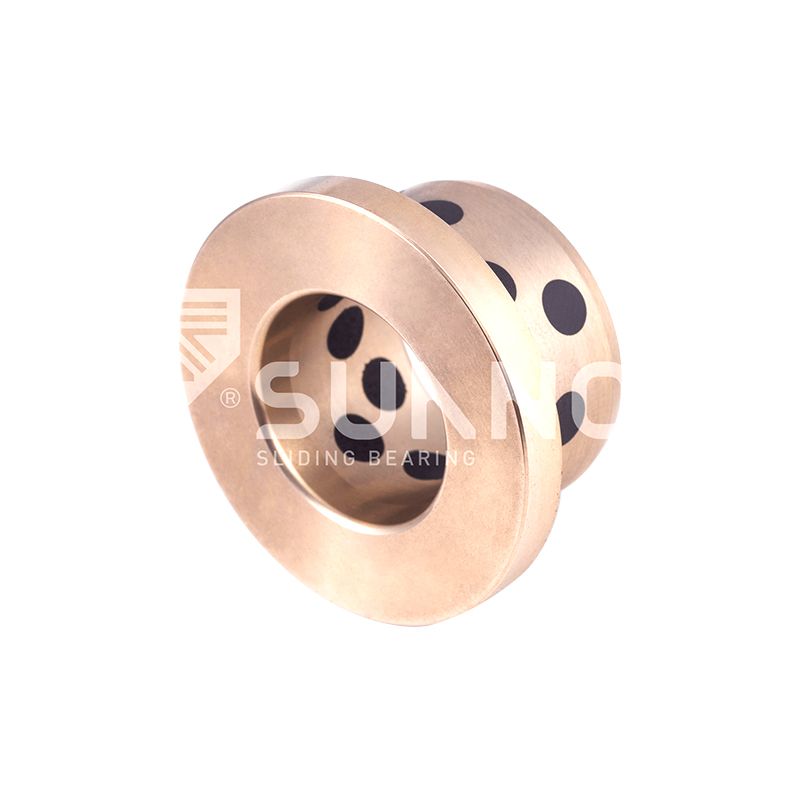

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing -

JDB Solid-lubricating Bearing JEGB/JEGBK Oiless Ejector Guide Bushing Oilless Ejector Bearing

JDB Solid-lubricating Bearing JEGB/JEGBK Oiless Ejector Guide Bushing Oilless Ejector Bearing -

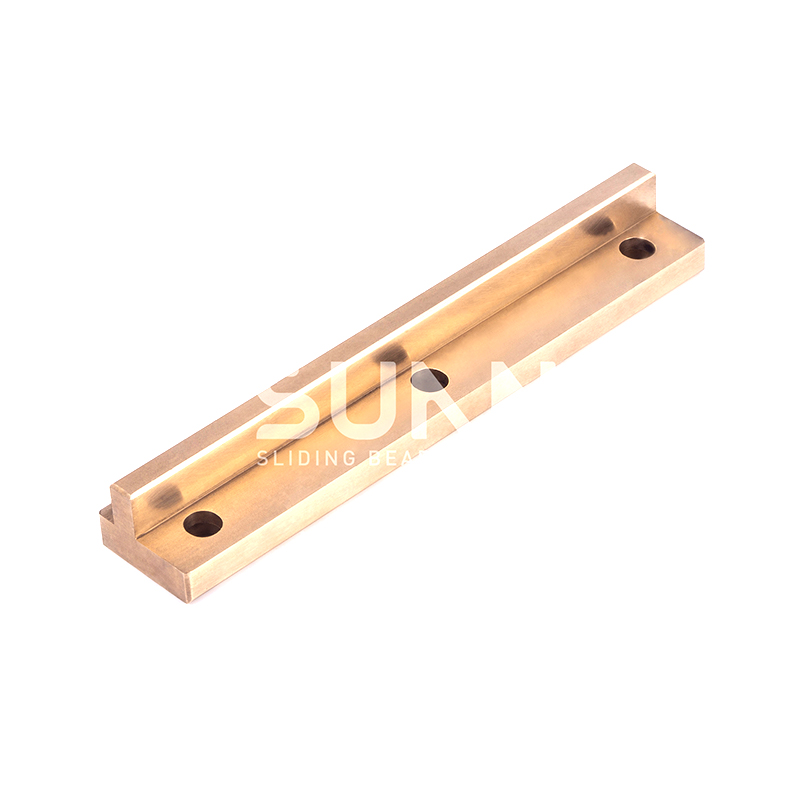

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components -

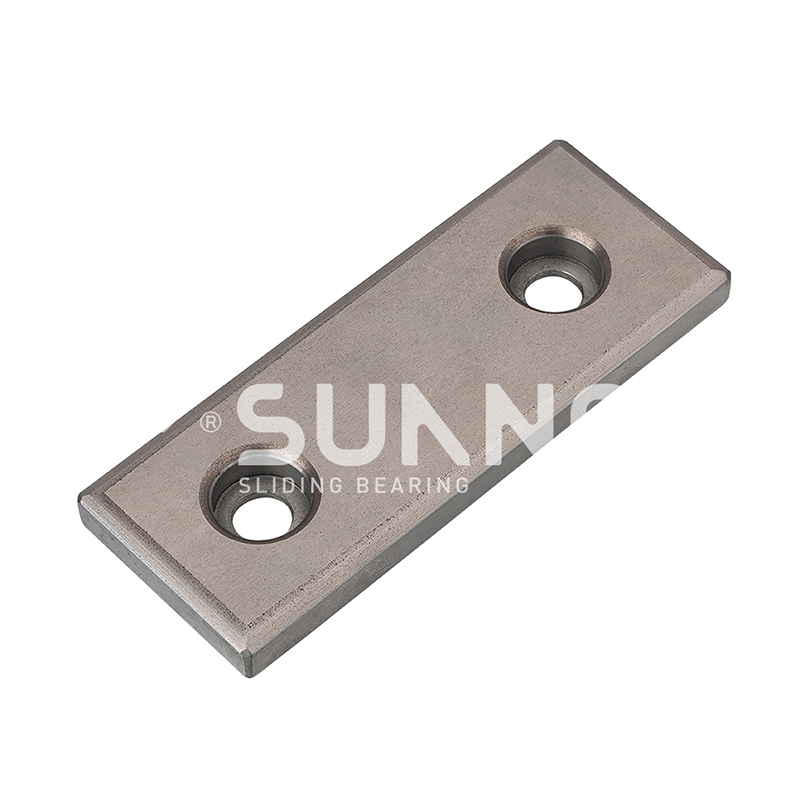

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications -

-

The Rise of Self-Lubricating Bearings: A Guide to Maintenance-Free Performance

Industry News-Why Choose Self-Lubricating Bearings?

In industrial applications, bearings are core components of any machinery. Traditional sliding bearings require continuous lubrication with oil or grease to reduce friction, minimize wear, and extend service life.

JFBB Metric Self-lubricating Oilless Graphite Flanged Bearings Bushings

However, this traditional lubrication method has several drawbacks:

- High maintenance costs: It demands regular inspection and frequent addition or replacement of lubricants, consuming significant labor and time.

- Environmental risks: Lubricant leaks can contaminate the work environment and surrounding equipment, potentially harming the environment.

- Operational limitations: In specific applications with high temperatures, dust, heavy loads, or limited access, traditional bearings often perform poorly.

The emergence of self-lubricating bearings (self-lubrication bearings) has completely changed this scenario. By using a special material microstructure, they automatically release a lubricating medium during operation, enabling long-term or even permanent maintenance-free performance.

Traditional vs. Self-Lubricating Bearings: Parameter Comparison

| Characteristic | Traditional Bearings (Require External Lubrication) | Self-Lubricating Bearings (self lubrication bearing) |

|---|---|---|

| Lubrication Method | Depends on an external lubrication system or manual application of lubricant. | Relies on its own material, no external lubrication needed. |

| Maintenance Frequency | Regular maintenance, requires inspection and lubricant replenishment. | Maintenance-free, can operate stably for a long time after installation. |

| Environmental Adaptability | Lubricating oil is easily affected by high temperatures, dust, etc., leading to unstable performance. | Performs stably in harsh environments such as high temperatures, dust, and humidity. |

| Operational Noise | Noise and vibration are noticeable with poor lubrication. | Operates smoothly with low noise. |

| Contamination Risk | Lubricant leaks or evaporates, posing a risk of environmental contamination. | Oilless operation, no contamination risk. |

| Installation & Operation | Requires an independent lubrication system, making installation complex. | Simple to install, no additional lubrication system required. |

The Core Technology of Self-Lubricating Bearings

The ability of self-lubricating bearings to be maintenance-free is rooted in their unique materials and design. Instead of relying on traditional lubricants, they achieve lubrication through their own structure, which primarily involves three key technologies:

1. Oilless Bushings: The Foundation of Self-Lubrication

Oilless bushings (oilless bushing) are one of the most common forms of self-lubricating bearings. These bushings are typically made of composite materials with solid lubricants—such as graphite, PTFE, or molybdenum disulfide (MoS₂)—embedded within their internal structure. As the bearing operates, friction-generated heat causes these solid lubricants to be released, forming a thin, solid lubricating film on the friction surface. This film reduces friction and prevents wear, enabling efficient operation in an “oilless” environment.

2. Plain Bearing Materials: The Determinant of Performance

The performance of a self-lubricating bearing is largely determined by the plain bearing materials (plain bearing materials) used. These materials can be broadly categorized into several types:

- Metal-based composites: Solid lubricants are evenly distributed within a metal matrix (e.g., copper, iron, aluminum). These materials offer high load capacity and temperature resistance, making them suitable for heavy-duty and harsh conditions.

- Engineering plastics: Using a polymer base, such as polyamide (PA) or polyoxymethylene (POM). These materials are corrosion-resistant, lightweight, and have a low friction coefficient, ideal for light-to-medium loads.

- Porous sintered metals: Produced through sintering, these bearings have a porous structure filled with oil. During operation, the oil seeps out, providing continuous lubrication.

3. Composite Bushings: The Perfect Blend of Performance

To meet more complex application requirements, composite bushings (composite bushing) have been developed. These bushings typically consist of multiple layers, with each layer serving a different function to optimize performance.

A PTFE composite bushing, for example, usually has three layers:

- Backing layer: A steel or bronze back for high load capacity and rigidity.

- Sintered layer: A porous bronze powder layer that enhances thermal conductivity and bonding strength.

- Sliding layer: A mixture of PTFE and solid lubricants that serves as the working surface, offering an extremely low friction coefficient and excellent wear resistance.

Three Self-Lubrication Technology Comparison

| Technology Type | Primary Composition | Load Capacity | Coefficient of Friction | Application Scenarios |

|---|---|---|---|---|

| Oilless Bushings | Solid lubricant with metal/plastic matrix | High to medium | Extremely low | Applications where oiling is impossible or contamination is a concern |

| Plain Bearing Materials | Single metal or engineering plastic matrix | High (metal) / Low (plastic) | Medium to low | Special load-bearing or corrosion-resistance needs |

| Composite Bushings | Multi-layer composite, e.g., steel/bronze/PTFE | Extremely high | Extremely low | All general industrial applications requiring high load capacity and low friction |

The Unique Advantages and Applications of Self-Lubricating Bearings

The core technology of self-lubricating bearings (self lubrication bearing) gives them distinct advantages over traditional bearings, allowing them to excel in demanding environments.

1. Maintenance-Free Bearings: A Tool for Cost and Efficiency

Maintenance-free bearings (maintenance free bearing) are the most significant feature of self-lubricating bearings. They eliminate the need for external lubrication systems and regular refueling, which leads to:

- Reduced maintenance costs: No need to allocate labor and time for routine lubrication and inspection.

- Extended equipment lifespan: A stable and reliable lubrication mechanism reduces wear, extending the life of the bearing and related equipment.

- Simplified mechanical design: No need for complex lubrication pipelines, pumps, or reservoirs, resulting in a more compact and lightweight equipment structure.

2. Dry Sliding Bearings: Experts in Harsh Environments

As dry sliding bearings (dry sliding bearing), self-lubricating bearings demonstrate remarkable adaptability in special conditions:

- High and low temperatures: While traditional lubricants can fail or degrade in extreme temperatures, self-lubricating materials remain stable.

- Dusty and wet environments: Lubricating oil can attract dust, forming an abrasive paste that accelerates wear. Self-lubricating bearings are unaffected and effectively prevent contaminant ingress.

- Food and medical industries: These fields demand high cleanliness. Oilless bushings eliminate the risk of contamination from lubricant leaks.

- Inaccessible locations: In applications like deep-sea equipment or aerospace components that are difficult to reach after installation, the maintenance-free feature is crucial.

3. Widespread Application Fields

Due to their outstanding performance, self-lubricating bearings have permeated nearly every industrial sector:

- Automotive industry: Widely used in engines, chassis, door hinges, and other components.

- Aerospace: Used in critical parts like landing gear and control systems.

- Construction machinery: Such as excavators and cranes, they operate stably in dusty and heavy-load environments.

- Home appliances and office equipment: In washing machines and printers, they provide quiet and smooth operation.

Traditional vs. Self-Lubricating Bearings: Application Comparison

| Characteristic | Traditional Bearings | Self-Lubricating Bearings (self lubrication bearing) |

|---|---|---|

| Typical Application Environment | Clean, maintainable, and moderately-temperatured environments. | Harsh environments such as high/low temperatures, dust, high humidity, and corrosion. |

| Food/Medical Sector | Risk of lubricant contamination, generally not suitable. | Oilless operation, meets hygiene standards, widely used. |

| Car Engine Internals | Requires continuous oil supply, complex design. | Can be used in some components to simplify design and reduce failure rates. |

| Maintenance Convenience | Requires regular downtime for maintenance. | Operates stably for a long time after installation, no downtime needed for maintenance. |

| Total Equipment Cost | Low bearing cost, but high costs for maintenance and lubrication systems. | Bearing cost may be slightly higher, but total long-term operating costs are lower. |

The Future of Self-Lubricating Bearings

Self-lubricating bearings (self lubrication bearing) have made great strides, but their future potential is still vast. As industries demand higher efficiency, reliability, and environmental sustainability, self-lubricating bearings are evolving toward more advanced and specialized forms.

1. Breakthroughs in New Materials and Processes

The future of self-lubricating bearings will increasingly depend on the research and development of new materials. The development of composites that are more resistant to high temperatures, corrosion, and have lower friction coefficients will expand their application into even more extreme conditions.

The company Zhejiang Shuangnuo Bearing Technology Co., Ltd., with its deep technical expertise in this field, represents this industry trend. Their use of advanced processes provides a solid foundation for the future of self-lubricating bearings:

- Centrifugal casting, continuous casting, and metal mold casting: These advanced casting techniques produce high-quality copper alloy products, providing premium raw materials for solid inlaid self-lubricating bearings. The stability and purity of these base materials are key to ensuring the final bearing's performance.

- Sintering technology: Used to produce bimetallic products, this advanced process combines different metal materials to achieve complementary advantages. For example, combining a wear-resistant copper alloy with a high-strength steel base creates a bearing with both high load capacity and excellent self-lubricating properties.

- In-house production and strict quality control: The company insists on producing its own raw materials and conducts multiple spectrometer tests, as well as commissioning national testing agencies for material and mechanical properties. This comprehensive quality control, from raw material to finished product, is essential for ensuring the reliability of self-lubricating bearings and is a standard the future industry must follow.

2. Integration of Intelligence and Customization

Future self-lubricating bearings will be more than just mechanical parts; they will be "smart components" integrated with intelligent technology. This includes:

- Embedded sensors: Integrating miniature sensors into bearings to monitor temperature, vibration, and wear in real-time, enabling predictive maintenance and further extending their maintenance-free period.

- Customized production: With the rise of additive manufacturing technologies like 3D printing, it will be possible to quickly produce self-lubricating bearings with specific shapes or performance characteristics to meet the demand for small batches and high precision.

3. Environmental and Sustainable Development

Self-lubricating bearings already offer environmental benefits, but future development will focus even more on sustainability:

- Lead-free materials: As environmental regulations become stricter, the R&D and application of eco-friendly materials like lead-free copper alloys will become mainstream.

- Recyclability: Research into more efficient ways to recycle and reuse self-lubricating bearing materials will reduce resource waste.

In conclusion, the future of self-lubricating bearings will be driven by new materials, innovative processes, intelligent integration, and sustainability. Companies like Zhejiang Shuangnuo Bearing Technology Co., Ltd., which are focused on technological research and production quality, will continue to drive innovation in this field, providing the global industry with more efficient, reliable, and environmentally friendly solutions.