-

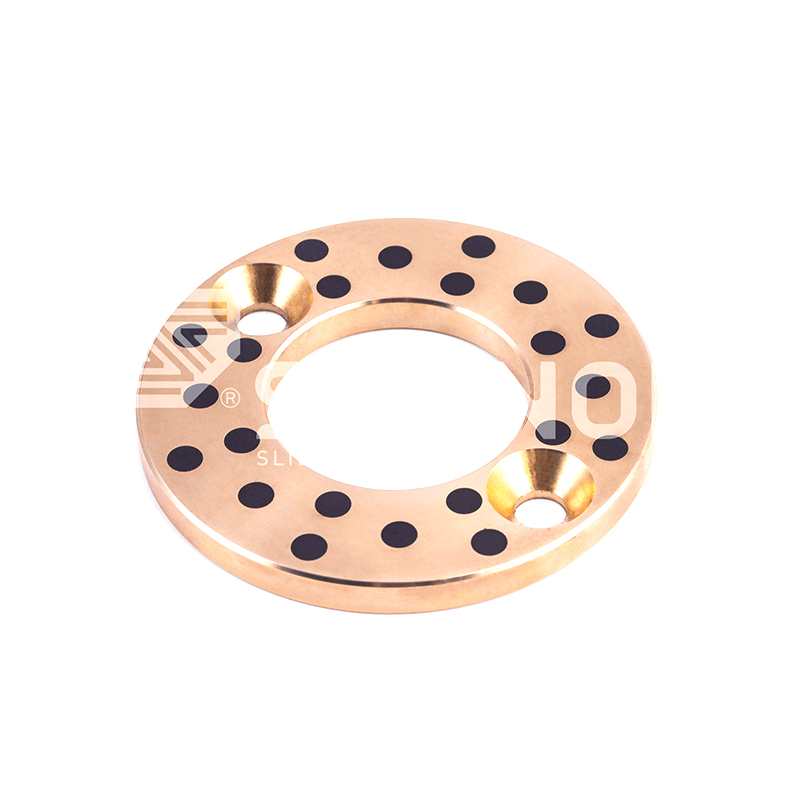

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing -

JDB Solid-lubricating Bearing JDB-5 Steel Embedded Wear Resistant Solid-lubricating Bearing

JDB Solid-lubricating Bearing JDB-5 Steel Embedded Wear Resistant Solid-lubricating Bearing -

-

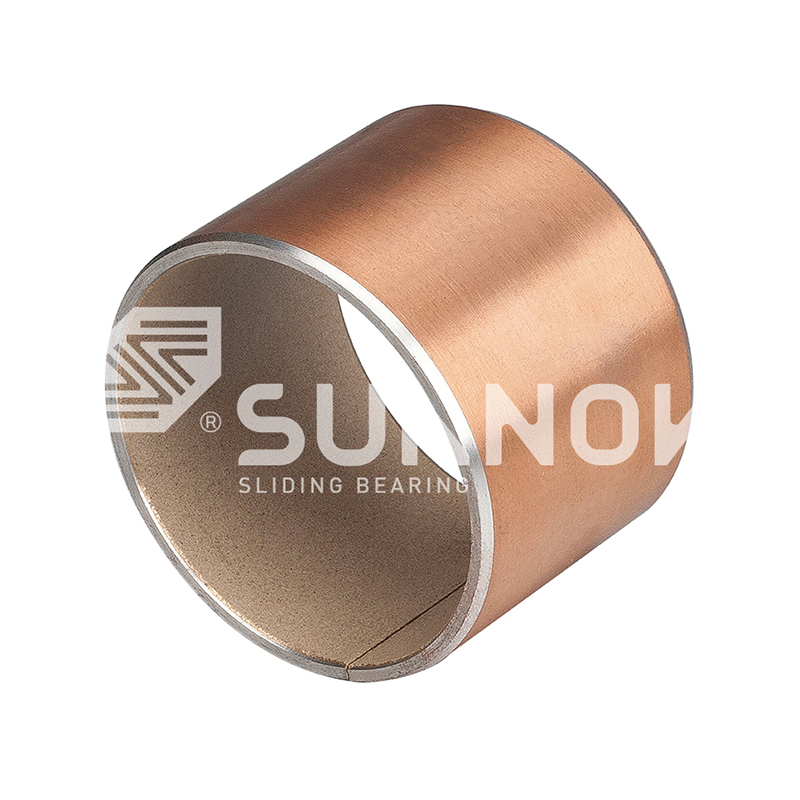

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing -

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush -

-

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

Optimizing Industrial Performance: A Comprehensive Guide to Solid Bronze Bushings

Industry News-- 1 Bronze Bushings: The Core Component of Industrial Machinery

- 2 I. Custom Size Cast Solid Bronze Bushings: Precisely Matching Your Needs

- 3 II. Corrosion-Resistant Marine Solid Bronze Bushings: The Ideal Choice for Harsh Marine Environments

- 4 III. Heavy-Duty Industrial Equipment Solid Bronze Bushings: Solutions for Demanding Conditions

- 5 IV. Self-Lubricating Solid Bronze Bearing Alternatives: Reducing Maintenance, Increasing Efficiency

- 6 Zhejiang Shuangnuo Bearing Technology Co., Ltd.: Your Self-Lubricating Bearing Expert

Bronze Bushings: The Core Component of Industrial Machinery

Solid bronze bushings play a crucial role in modern industry, serving as the foundation for the smooth and efficient operation of countless mechanical devices. These seemingly simple components effectively reduce friction, support loads, and extend equipment life. This article will delve into the unique characteristics of different types of bronze bushings and their exceptional performance in specific applications, helping you better understand and select the ideal solution for your needs.

JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings

I. Custom Size Cast Solid Bronze Bushings: Precisely Matching Your Needs

Cast solid bronze bushings are common friction pair components in industrial applications, formed by pouring molten bronze alloy into molds. This manufacturing process imbues bronze bushings with excellent wear resistance, good thermal conductivity, and corrosion resistance, making them ideal for bearing and bushing applications.

In many industrial scenarios, standard-sized bushings are often insufficient to meet the specific requirements of equipment. For example, some older machinery may require non-standard replacement parts, or new mechanical designs might demand extremely high precision in fit. In such cases, custom size bronze bushings become incredibly important. They ensure a perfect fit between the bushing and the shaft or bore, thereby minimizing wear, reducing noise, and significantly extending the equipment's operational lifespan.

In customized production, die casting (Die Casting) is a commonly used precision casting process. It involves applying high pressure to a mold cavity, causing the molten bronze alloy to solidify rapidly. Bronze bushings produced by die casting offer advantages such as high dimensional accuracy, excellent surface finish, and dense internal structure, making them particularly suitable for customized components that demand strict tolerances and surface quality.

Whether for the pivot points of heavy machinery or critical supports in specialized equipment, custom size cast solid bronze bushings provide tailored solutions, ensuring the precision and reliability of mechanical systems.

II. Corrosion-Resistant Marine Solid Bronze Bushings: The Ideal Choice for Harsh Marine Environments

The marine environment presents one of the most formidable challenges to mechanical components. Seawater, salt spray, humidity, and various microorganisms and chemical substances all severely test the material's corrosion resistance and durability. In such extreme conditions, corrosion-resistant marine solid bronze bushings become indispensable key components in ships and offshore engineering equipment, owing to their unique material advantages.

Bronze as a copper alloy, due to its inherent chemical inertness, exhibits exceptional corrosion resistance, especially in saltwater environments. Compared to some steel materials, bronze is less prone to electrochemical corrosion in seawater and can effectively resist pitting and crevice corrosion caused by chloride ions, thus ensuring the bushing maintains its structural integrity and functionality even after prolonged immersion or exposure to marine atmosphere.

Marine bushings not only need to resist corrosion but also must meet high strength, high wear resistance, and long lifespan requirements to withstand the continuous loads, vibrations, and friction generated by vessels during navigation and operation. Bronze alloys, especially special grades containing elements like tin, aluminum or nickel, can significantly enhance their hardness, wear resistance, and mechanical strength, allowing them to perform excellently even under high-speed rotation and heavy loads.

Key application areas for marine bronze bushings include:

- Ship Propulsion Systems: Propeller shaft bushings, rudder bearings, etc.

- Offshore Platform Equipment: Cranes, winches, hydraulic cylinders, and other critical moving parts.

- Fishery and Port Machinery: Net hauling machines, dock crane bearings, etc.

When selecting marine bronze bushings, in addition to considering their corrosion resistance and mechanical properties, the following comparative parameters should be taken into account:

| Parameter | Explanation | Selection Considerations |

|---|---|---|

| Alloy Composition | Different bronze grades (e.g., tin bronze, aluminum bronze, nickel aluminum bronze) have varying corrosion resistance and mechanical properties. | Tin bronze (e.g., C90300, C90500) is commonly used for general marine bearings; aluminum bronze (e.g., C95400, C95500) offers higher strength and wear resistance for heavy-duty and high-wear applications. |

| Tensile Strength | The material's ability to resist breaking under tension, measuring its load limit. | Choose based on the maximum load and impact load the bushing will bear to prevent plastic deformation or fracture. |

| Yield Strength | The maximum stress a material can withstand before permanent deformation, reflecting its resistance to deformation. | A critical design parameter to ensure the bushing maintains its geometric shape stability under working loads. |

| Hardness (HB) | The material's resistance to indentation or scratching, closely related to wear resistance. | Marine bushings typically require high hardness to cope with abrasive wear and contact fatigue. |

| Coefficient of Friction | The magnitude of resistance between moving parts, affecting energy loss and temperature rise. | A lower coefficient of friction reduces energy consumption, lowers heat generation, and extends the life of the bushing and shaft. |

| Surface Roughness | The smoothness of the bushing's contact surface. | Proper surface roughness helps form a stable lubricating oil film, reducing friction and wear. |

| Thermal Conductivity | The material's ability to conduct heat. | Good thermal conductivity helps dissipate heat generated by friction, preventing the bushing from overheating and failing. |

Proper selection and installation of high-quality corrosion-resistant marine solid bronze bushings are crucial for ensuring the long-term reliable operation of ships and marine equipment in harsh marine environments.

III. Heavy-Duty Industrial Equipment Solid Bronze Bushings: Solutions for Demanding Conditions

In many industrial sectors, machinery often operates under extreme conditions, such as bearing immense loads, frequent impacts, continuous vibration, or even in abrasive environments. These heavy-duty conditions pose severe challenges to every component of the equipment. Heavy-duty industrial equipment solid bronze bushings are precisely designed to meet such demands.

Why choose solid bronze bushings for heavy-duty applications?

Bronze, as an excellent bearing material, offers several irreplaceable advantages in heavy-duty applications:

- Exceptional Load-Bearing Capacity and Compressive Strength: Bronze alloys possess high hardness and superior compressive properties, enabling them to withstand immense radial and axial loads without permanent deformation or failure.

- Outstanding Wear Resistance: Bronze alloys typically contain elements like lead and tin, which form soft phases that help reduce the coefficient of friction and minimize wear, especially in less-than-ideal lubrication conditions. They also exhibit good resistance to abrasive wear.

- Stability in Extreme Conditions: Compared to some other materials, bronze can maintain its mechanical properties and operational stability even with significant temperature fluctuations or slight misalignment.

- Shock Absorption and Noise Reduction: Bronze materials have a certain elasticity, effectively absorbing shocks and vibrations, which helps reduce equipment operating noise and protects other components.

Typical applications of heavy-duty industrial equipment solid bronze bushings include:

- Mining Machinery: Crushers, ball mills, conveyor rollers, and other equipment operating in dusty, heavy-load environments.

- Construction Equipment: Connecting pins and slewing bearings for heavy engineering machinery like excavators, bulldozers, and cranes.

- Metallurgical Equipment: Rolling mills, continuous casting machines, and other components subjected to high temperatures and heavy loads.

- Large Pumps and Valves: Bearing supports in pump bodies and valves used for conveying high-viscosity or abrasive media.

When selecting heavy-duty industrial equipment solid bronze bushings, the following comparative parameters are crucial:

| Parameter | Explanation | Selection Considerations |

|---|---|---|

| Maximum Permissible Pressure (P-value) | The maximum unit area pressure the bushing can withstand at a specific speed, typically in MPa. | This is one of the most important parameters; it must be greater than the ratio of the maximum force in equipment operation to the bushing's effective bearing area. |

| Maximum Sliding Velocity (V-value) | The maximum relative motion speed the bushing can withstand at a specific load, typically in m/s. | Must be greater than or equal to the product of the shaft's maximum RPM and the bushing's diameter. |

| PV Value (Pressure-Velocity Product) | A measure of the bushing's overall performance under specific load and speed, reflecting its heat dissipation and wear limits. | This is a critical design parameter, ensuring the bushing does not fail due to overheating or excessive wear under given operating conditions. It should typically be below the material's permissible PV value. |

| Wear Rate | The amount of material wear per unit time or per unit friction travel; lower is better. | Directly affects the bushing's service life and equipment maintenance cycles. |

| Impact Toughness | The material's ability to resist impact loads, measuring its performance in resisting brittle fracture upon impact. | For equipment frequently subjected to impacts (e.g., crushers), this is a key performance indicator. |

| Operating Temperature Range | The maximum and minimum temperatures at which the bushing can operate stably. | Must match the actual operating temperature of the equipment to prevent material performance degradation or failure. |

| Shaft Fit Clearance | The dimensional difference between the bushing's inner diameter and the shaft's outer diameter. | Proper fit clearance is vital for forming an oil film, dissipating heat, and compensating for thermal expansion. Incorrect clearance can lead to accelerated wear or seizing. |

Maintenance and Lifespan:

To maximize the lifespan of heavy-duty bronze bushings, proper installation and continuous lubrication are essential. Ensuring the cleanliness and sufficiency of lubricants, along with regular inspection of bushing wear, can significantly reduce failure rates and maintenance costs.

By carefully evaluating the above parameters and selecting high-quality heavy-duty industrial equipment solid bronze bushings, companies can effectively enhance equipment reliability and operational efficiency, reduce downtime, and ultimately lower overall operating costs.

IV. Self-Lubricating Solid Bronze Bearing Alternatives: Reducing Maintenance, Increasing Efficiency

In many industrial applications, traditional lubrication methods face numerous challenges, such as lubricant contamination, high maintenance costs, or the inability to effectively lubricate in specific working environments. Self-lubricating solid bronze bearing alternatives have emerged to address these issues. They achieve lubrication through the material's inherent properties, significantly reducing the need for external lubrication, enhancing equipment efficiency, and lowering long-term operating costs.

The advantages of self-lubricating technology include:

- Reduced or Eliminated Need for External Lubrication: This translates to less downtime, lower maintenance costs, and a cleaner working environment.

- Excellent Performance in Insufficient or Non-Lubricated Conditions: Self-lubricating bearings maintain stable performance even in extreme conditions like high temperatures, dusty environments, vacuums, or submerged applications.

- Reduced Maintenance Costs and Downtime: Maintenance-free or low-maintenance requirements make equipment operation more reliable, reducing manual intervention and spare parts inventory.

Common types of self-lubricating bronze bearings and their lubrication mechanisms:

- Solid Lubricant Embedded Type: Solid lubricants such as graphite or molybdenum disulfide are uniformly embedded within a bronze matrix. When the bearing operates, the solid lubricant gradually releases and forms a lubricating film on the friction surface, providing continuous lubrication.

- Porous Structure Oil-Impregnated Type (Powder Metallurgy): Porous bronze matrices are manufactured using powder metallurgy, and then lubricating oil is impregnated into these pores. During operation, heat generated by the bearing causes the oil to expand and flow to the friction surface; when operation stops, the oil is re-absorbed into the pores.

When to consider using self-lubricating bronze bearing alternatives?

- When existing bearings frequently fail due to insufficient lubrication or lubricant contamination.

- When equipment is located in hard-to-access areas or where maintenance costs are high.

- When strict requirements for environmental cleanliness exist, and lubricant leakage is undesirable (e.g., food processing, medical equipment).

- When operating temperatures are too high or too low, causing traditional lubricants to fail.

Potential application areas include:

- Food Processing Equipment: Requires extremely high levels of cleanliness and hygiene.

- Textile Machinery: To reduce oil stains on products.

- Automation Equipment and Robotics: Demands maintenance-free and high reliability.

- High-Temperature Furnace Equipment: Where traditional lubricants cannot withstand extreme temperatures.

When selecting self-lubricating solid bronze bearing alternatives, the following comparative parameters are crucial:

| Parameter | Explanation | Selection Considerations |

|---|---|---|

| Self-Lubrication Mechanism | Solid lubricant embedded, porous oil-impregnated, or other composite types. | Choose the most suitable lubrication method based on working environment, load, and speed. |

| Maximum PV Value | The upper limit of the pressure-velocity product the bearing can withstand under self-lubricating conditions. | Ensure the selected bearing's PV value is greater than the actual PV value of the equipment to prevent overheating and premature wear. |

| Wear Life | The operating time or friction distance until the bearing reaches its wear limit under specific operating conditions. | Directly related to the equipment's maintenance-free period and overall lifespan. |

| Applicable Temperature Range | The temperature range within which the self-lubricating bearing can operate stably without losing performance. | Must match the actual working temperature of the equipment. |

| Corrosion Resistance | The ability to resist corrosion in humid, chemical media, etc. | For special environments, consider the bronze alloy's inherent corrosion resistance and lubricant compatibility. |

| Load Capacity | The maximum static and dynamic load the bearing can withstand. | Select based on the actual load requirements of the equipment. |

Zhejiang Shuangnuo Bearing Technology Co., Ltd.: Your Self-Lubricating Bearing Expert

Zhejiang Shuangnuo Bearing Technology Co., Ltd. is a manufacturer specializing in the production of various self-lubricating copper alloy products. We utilize advanced processes such as centrifugal casting, continuous casting, and metal mold casting to ensure quality control of raw materials from the source. Our main products include brass, aluminum bronze, tin bronze, and other copper alloy products manufactured according to national standard grades. Building on this, we further process and produce various solid inlaid self-lubricating bearing products. Simultaneously, we employ sintering technology to produce bimetallic products and many other types of products.

Since its establishment nearly 10 years ago, the company has focused on the research, development, and production of various new self-lubricating bearings. We have always insisted on independent casting production of raw materials to ensure product quality from the source. During the casting process, we implement full-process monitoring, and the finished product undergoes three spectrometer tests—before, during, and after the furnace—to confirm the material composition. We regularly commission national testing agencies to test the material composition and mechanical properties of our products, and authoritative test reports can be provided to customers in need.

Zhejiang Shuangnuo Bearing Technology Co., Ltd. implements integrated production from raw material to finished product processing. The company possesses more than 80 sets of advanced CNC machine tools, CNC lathes, machining centers, and other major equipment. Our strong production capacity ensures that material production is organized for customers at the earliest opportunity, significantly shortening the production cycle and providing efficient, high-quality self-lubricating solutions.