-

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings -

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing -

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing -

Oil-retaining Bimetallic Bearing Self-Lubricating 200# P20 Oil-Retaining Steel Bearing Plate - Low Friction Wear-Resistant

Oil-retaining Bimetallic Bearing Self-Lubricating 200# P20 Oil-Retaining Steel Bearing Plate - Low Friction Wear-Resistant -

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip -

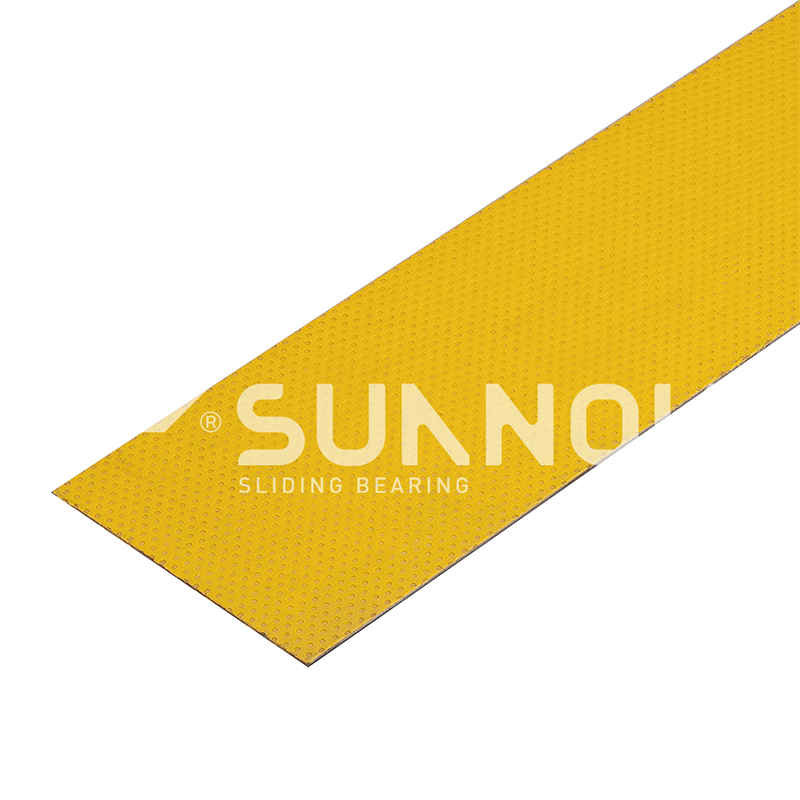

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE -

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery -

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

The Power of Bronze: Enhancing Durability and Reliability with Solid Bronze Bushings

Industry News-- 1 1. The Role of Solid Bronze Bushings in Industrial Machinery

- 2 2. Optimizing Industrial Performance: A Comprehensive Guide to Solid Bronze Bushings

- 3 3. Enhancing Reliability: Maintenance and Troubleshooting for Solid Bronze Bushings

- 4 4. Case Studies: Real-World Applications of Solid Bronze Bushings

- 4.1 1. Heavy Industry: The "Heart" of Mining and Construction Equipment

- 4.2 2. Marine Environments: Guardians of Ships and Underwater Machinery

- 4.3 3. Precision Engineering: Core Components of High-Precision Equipment

- 4.4 4. Application Examples from Company Profile: Zhejiang Shuangnuo Bearing Technology Co., Ltd.

1. The Role of Solid Bronze Bushings in Industrial Machinery

Solid bronze bushings, also known as plain bearings or sleeve bearings, are essential components in industrial machinery. They support rotating or sliding parts and reduce friction between them. While modern materials are constantly evolving, bronze remains an indispensable choice in many demanding applications due to its unique combination of properties.

Bronze is a copper-based alloy, often mixed with tin, aluminum, or other elements. Its unique composition provides exceptional strength, durability, and corrosion resistance, giving it a long and successful history in mechanical engineering.

Key Advantages: Why Choose Solid Bronze Bushings?

The primary reason for choosing solid bronze bushings is their ability to meet the stringent requirements of industrial applications for high load, wear resistance, and reliability. Here are their core advantages:

- High Load-Bearing Capacity: The hardness and strength of bronze allow it to withstand extremely high radial and axial loads without significant deformation. This is crucial in applications like heavy-duty machinery, construction equipment, and mining equipment.

- Excellent Wear Resistance: The composition of bronze alloys helps them resist wear and abrasion, ensuring a long service life even under less-than-ideal lubrication conditions.

- Strong Corrosion Resistance: Bronze has a high resistance to moisture, saltwater, and many chemicals. This makes it an excellent choice for use in wet or corrosive environments such as marine applications, pumps, and valves.

- Good Thermal Conductivity: Bronze’s good thermal conductivity allows it to effectively dissipate heat generated by friction, preventing equipment from overheating and extending the life of the bearing and adjacent components.

Comparison of Bronze with Other Bushing Materials

| Feature | Solid Bronze Bushings | Plastic Bushings (e.g., Nylon, PTFE) | Sintered Bronze Bushings |

| Load Capacity | High, suitable for heavy loads and high-pressure applications | Low, not suitable for heavy loads | Medium, suitable for moderate loads |

| Wear Resistance | Excellent, especially under heavy-load, low-speed conditions | Good, but shorter lifespan than bronze | Good, often self-lubricating |

| Lubrication Needs | Usually requires external lubrication (oil or grease) | Typically self-lubricating, low friction coefficient | Self-lubricating, oil-impregnated pores |

| Corrosion Resistance | Very good, especially for wet or corrosive environments | Excellent, but sensitive to certain chemicals | Good, but not as good as solid bronze |

| Temperature Range | Wide, can withstand high temperatures | Relatively limited, restricted by the plastic material itself | Wide, but depends on the lubricant type |

| Impact Loads | Excellent, can withstand impacts and vibrations | Poor, prone to deformation or fracture | Medium |

2. Optimizing Industrial Performance: A Comprehensive Guide to Solid Bronze Bushings

Choosing and using the correct solid bronze bushings is key to optimizing industrial performance and extending equipment life. This section will delve into how to maximize their efficiency through material selection, design, and proper installation.

Material Science Breakdown: Different Bronze Alloys

When selecting a solid bronze bushing, it is crucial to understand the properties of different bronze alloys. Each alloy has a unique composition and performance, making it suitable for specific operating conditions.

- Tin Bronze (e.g., CuSn8, CuSn12): With tin as the primary alloying element, these bushings offer excellent wear resistance and high load capacity. They perform exceptionally well in high-pressure, medium-to-low-speed applications, such as the pivot points of heavy machinery.

- Leaded Bronze (e.g., CuPb10Sn10, CuPb15Sn7): The addition of lead provides better self-lubricating and anti-friction properties. This makes them particularly useful in applications where lubrication is poor or for emergency run-on conditions, such as in internal combustion engines and compressors.

- Aluminum Bronze (e.g., CuAl10Fe3Mn2): With aluminum as the primary alloying element, these bushings have higher strength and exceptional corrosion resistance, especially in saltwater environments. They are often used in marine equipment, aircraft landing gear, and high-strength hydraulic cylinders.

Design and Selection: How to Match the Right Bushing

Selecting the right solid bronze bushing is a systematic process that requires considering the following parameters:

| Parameter | Description | Selection Guide |

| Radial Load | The force on the bushing perpendicular to the shaft axis | Determine the load size and select a bronze alloy with sufficient load capacity (e.g., tin bronze). |

| Axial Load | The force on the bushing parallel to the shaft axis | Consider thrust bearings or bushings with a flange to withstand axial forces. |

| Sliding Speed | The relative speed between the shaft and the bushing | High-speed applications require better heat dissipation and lubrication, possibly leaded bronze or bushings with special lubrication designs. |

| Operating Temperature | The ambient and friction-generated temperature of the bushing | For high-temperature environments, select an alloy that can withstand thermal expansion and resist softening. |

| Lubrication Conditions | The type, supply method, and frequency of lubrication | In poor or unstable lubrication environments, prioritize leaded bronze alloys. |

| Environmental Factors | Corrosive substances, dust, humidity, etc. | For saltwater or chemical environments, choose corrosion-resistant aluminum bronze. |

Installation Best Practices: Ensuring Trouble-Free Operation

Proper installation is the final step in ensuring solid bronze bushings deliver maximum performance and a long service life.

- Surface Preparation: Before installation, ensure that the bore and the bushing's outer diameter are clean, free of burrs, and scratches.

- Press-Fitting Method: Use a hydraulic press or arbor press for installation. The pressing process should be smooth and even to prevent bushing deformation or damage.

- Alignment Correction: After installation, check the alignment of the bushing and the bore to ensure they are perfectly concentric. This prevents uneven wear.

- Initial Lubrication: Before the equipment's first run, be sure to fully lubricate the bushing according to the manufacturer's recommendations.

By following these guidelines, you can not only ensure the proper function of solid bronze bushings but also significantly enhance the overall performance and reliability of your equipment.

3. Enhancing Reliability: Maintenance and Troubleshooting for Solid Bronze Bushings

To ensure the long-term reliability of solid bronze bushings, regular maintenance and timely troubleshooting are crucial. A comprehensive maintenance plan can extend the bushing's service life and prevent costly downtime and equipment damage caused by bushing failure.

Bushing Lifespan and Influencing Factors

The service life of solid bronze bushings is influenced by various factors. Understanding these is fundamental to developing an effective maintenance strategy.

- Load and Speed: High loads and speeds accelerate wear and increase friction-generated heat.

- Lubrication Conditions: Lack of or improper lubrication is the most common cause of premature bushing failure.

- Contamination: Contaminants like dust, sand, and metal shavings on the friction surface can cause severe wear and scratches.

- Environmental Temperature: Extreme high or low temperatures can affect lubricant performance, thereby impacting the bushing's lifespan.

Preventive Maintenance: Keeping Bushings in Top Condition

An effective preventive maintenance plan should include the following key steps:

- Develop a Lubrication Schedule: Based on manufacturer recommendations and actual operating conditions, determine the optimal lubrication frequency and lubricant type. Record lubrication times and ensure the correct amount of lubricant is used each time.

- Regular Inspections: Periodically check the condition of the solid bronze bushings, including:

- Visual Inspection: Check for cracks, scratches, or uneven wear patterns.

- Temperature Monitoring: Use an infrared thermometer to monitor the surface temperature of the bushing. Abnormal heat is often an early sign of poor lubrication or overloading.

- Noise Checks: Unusual noises, like squeaking or grinding, may indicate insufficient lubrication or excessive clearance between the bushing and the shaft.

- Maintain Cleanliness: Ensure the work environment is clean to prevent contaminants from entering the bushing area. Install protective covers or seals where necessary.

Common Issues and Solutions: A Troubleshooting Guide

During the use of solid bronze bushings, several common problems may arise. Early identification and resolution can prevent more serious consequences.

| Common Problem | Possible Causes | Solution |

| Premature Wear | Insufficient or improper lubrication; contamination; overloading or high pressure. | Check and improve the lubrication schedule; clean the working environment; check for equipment overload. |

| Bushing Overheating | Poor lubrication; insufficient clearance; overloading; misalignment. | Increase lubrication frequency or use a suitable lubricant; check and correct the clearance between the bushing and the shaft; check equipment alignment. |

| Abnormal Noise | Insufficient lubricant; excessive clearance; vibration. | Replenish or replace the lubricant; check and replace worn bushings; check for equipment balance. |

| Bushing Cracking | Improper installation (e.g., forceful pressing); material fatigue; excessive impact loads. | Use the correct installation tools and methods; check for abnormal impact loads on the equipment; replace the bushing. |

4. Case Studies: Real-World Applications of Solid Bronze Bushings

Solid bronze bushings play a vital role across a wide range of industrial sectors. These case studies showcase their superior performance and reliability in different demanding environments.

1. Heavy Industry: The "Heart" of Mining and Construction Equipment

In the mining and construction industries, equipment is often exposed to harsh environments with high loads, strong impacts, and significant contamination. Pivot points and linkages of heavy machinery like excavators, bulldozers, and cranes are subject to the most severe wear.

- Application Scenario: The boom, stick, and bucket linkages of an excavator. These areas withstand immense radial and axial loads and frequent impacts.

- Solution: Use **solid bronze bushings** made from high-strength tin bronze alloys. This alloy offers excellent wear resistance and compressive strength, enabling it to withstand these severe operating conditions.

- Performance Advantage: **Solid bronze bushings** ensure the smooth and reliable operation of these critical connections, reducing the increased clearance and loss of operational precision caused by wear, thereby significantly extending the equipment's service life.

2. Marine Environments: Guardians of Ships and Underwater Machinery

The marine environment presents a significant challenge to mechanical components due to its high corrosiveness and humidity. Traditional steel bearings in saltwater can easily rust and corrode.

- Application Scenario: Ship propeller shafts, rudders, and lifting equipment on offshore platforms.

- Solution: Select **solid bronze bushings** made from aluminum bronze alloys, which have excellent corrosion resistance. The aluminum in these bronze bushings forms a dense oxide layer that effectively resists saltwater corrosion.

- Performance Advantage: Compared to other materials, aluminum bronze bushings have a longer service life in marine environments, reducing the frequency of maintenance and replacement and ensuring the safety of equipment operation.

3. Precision Engineering: Core Components of High-Precision Equipment

Although **solid bronze bushings** are often used in heavy-duty applications, they also play a crucial role in equipment requiring high precision and stability.

- Application Scenario: Certain high-precision CNC machine tools and rotating mechanisms on automated production lines.

- Solution: Use **solid bronze bushings** with specific compositions and high-precision machining.

- Performance Advantage: The damping properties and good thermal conductivity of bronze help maintain the equipment's operational accuracy and stability, reducing the impact of vibration and thermal deformation on machining quality.

4. Application Examples from Company Profile: Zhejiang Shuangnuo Bearing Technology Co., Ltd.

Zhejiang Shuangnuo Bearing Technology Co., Ltd. specializes in the production of various self-lubricating copper alloy products using centrifugal casting, continuous casting, and other processes. The company produces products like brass, aluminum bronze, and tin bronze, which can serve as the basis for **solid bronze bushings** or be further processed into self-lubricating bearings.

- Technological Advantages: The company insists on independently casting its raw materials and performs three-stage spectroscopic testing to ensure the material composition of the bronze alloys meets standards. This rigorous quality control at the source guarantees that the **solid bronze bushings** they produce have reliable mechanical properties.

- Product Applications: For example, the tin bronze products the company manufactures can be applied in the heavy machinery sector mentioned earlier, meeting the demand for high load capacity and wear resistance. The aluminum bronze products can satisfy the special requirements for corrosion resistance in marine environments. Furthermore, their bimetallic products, produced using sintering technology, offer new solutions for specific applications that require both high load capacity and self-lubrication.

- Production Capability: With over 80 sets of advanced CNC machine tools and machining centers, the company ensures an integrated production process from raw material to finished product. This strong production capacity allows for timely material production for customers, shortening the overall production cycle and ensuring the reliable application of various customized **solid bronze bushings** in different industries.

Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing