-

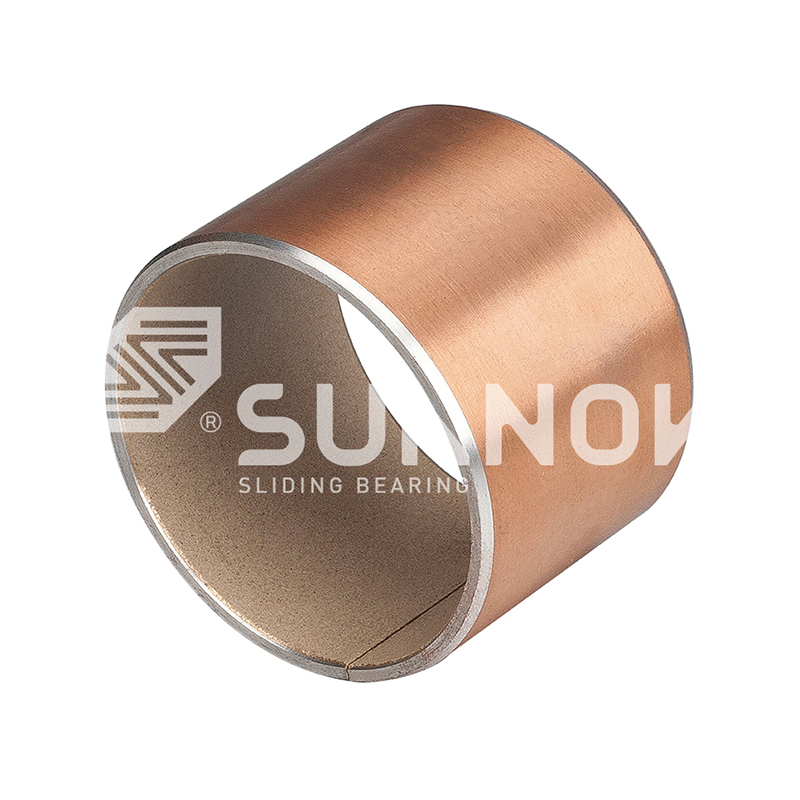

JDB Solid-lubricating Bearing JDB650 Self-Lubricating Brass Bushing Oilless Bearings

JDB Solid-lubricating Bearing JDB650 Self-Lubricating Brass Bushing Oilless Bearings -

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing -

JDB Solid-lubricating Bearing JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing

JDB Solid-lubricating Bearing JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing -

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing -

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing -

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

-

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications

How to Determine Whether Self-Lubricating Bronze Bearings Need Replacement

Industry News-- 1 1. Recognizing the Common Signs of Bearing Wear and Failure

- 2 2. Understanding the Lifespan and Failure Modes of Self-Lubricating Bearings

- 3 3. A Step-by-Step Guide to Bearing Inspection and Assessment

- 4 4. Troubleshooting Common Problems: When to Repair vs. Replace

- 5 5. The Cost-Benefit Analysis of Proactive Bearing Replacement

- 6 FAQ

- 6.1 What is the most accurate way to check bronze bearing clearance without disassembly?

- 6.2 Can a worn self-lubricating bronze bearing be repaired, or must it always be replaced?

- 6.3 How does improper installation shorten the life of a self-lubricating bronze bearing?

- 6.4 What are the consequences of running a self-lubricating bearing beyond its recommended clearance limits?

- 6.5 Are there any warning signs that appear long before a self-lubricating bearing completely fails?

Self-lubricating bronze bearings are renowned for their durability and long service life in demanding applications. However, like all mechanical components, they have a finite lifespan and will eventually require replacement. Knowing precisely when to replace them is crucial for preventing unexpected downtime, avoiding costly secondary damage to machinery, and maintaining optimal operational efficiency. This comprehensive guide provides a detailed framework for assessing the condition of your self-lubricating bronze bearings, outlining the key signs of wear, measurement techniques, and decision-making criteria to help you perform timely and effective maintenance.

Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing

1. Recognizing the Common Signs of Bearing Wear and Failure

The first step in determining the need for replacement is a thorough visual and operational inspection. Often, the machinery itself will provide clear indicators that a bearing is approaching the end of its useful life. Proactive monitoring for these signs can help you schedule replacements during planned maintenance windows, rather than reacting to a catastrophic failure. The most common symptoms are often related to changes in the machine's performance and physical characteristics.

- Increased Noise and Vibration: A pronounced humming, grinding, or squealing sound that wasn't present before is a classic indicator of excessive wear. Vibration levels will also typically increase as the bearing clearance grows.

- Excessive Heat Generation: While bearings operate at elevated temperatures, a sudden or significant spike in temperature at the bearing housing suggests increased friction, often due to lubricant depletion or seizure.

- Abnormal Shaft Movement or Play: If you can physically feel or measure movement of the shaft within the bearing that exceeds manufacturer specifications, it is a direct sign of significant wear.

- Visible Contamination or Debris: The presence of bronze-colored dust or particles around the bearing housing indicates active abrasive wear of the bearing material.

1.1. How to measure bronze bearing wear accurately

To move from subjective observation to objective decision-making, accurate measurement is essential. Understanding how to measure bronze bearing wear accurately allows maintenance teams to quantify the level of degradation and compare it against established tolerances. This process typically involves a combination of simple tools and precise instruments.

- Visual Inspection for Scoring and Pitting: After disassembly, look for deep scratches (scoring) or surface cavities (pitting) on the bearing's inner diameter. These are signs of abrasive wear and fatigue, respectively.

- Using Dial Gauges for Clearance Check: A dial indicator is used to measure the radial clearance between the shaft and the bearing. Compare the measured value to the manufacturer's recommended maximum allowable clearance.

- Ultrasonic Thickness Testing: For critical applications, non-destructive ultrasonic testing can measure the remaining wall thickness of the bearing without disassembling the entire unit, providing a clear picture of material loss.

| Measurement Method | What It Assesses | Tool Required |

| Dial Gauge Measurement | Radial Internal Clearance | Dial Indicator |

| Micrometer/Caliper | Bearing ID/OD and Wall Thickness | Outside/Inside Micrometer |

| Ultrasonic Testing | Remaining Wall Thickness (in situ) | Ultrasonic Thickness Gauge |

2. Understanding the Lifespan and Failure Modes of Self-Lubricating Bearings

The service life of a self-lubricating bronze bearing is not a fixed number of hours; it is a function of its operating environment and load conditions. A critical question for maintenance planners is self-lubricating bronze bearing lifespan and failure modes. By understanding the common ways these bearings fail, you can better diagnose issues and predict replacement intervals.

- Normal Wear-Out: The gradual, predictable wearing down of the bearing surface and depletion of the solid lubricant until clearances become excessive.

- Overload Failure: Applying a load beyond the bearing's static or dynamic capacity can cause plastic deformation, cracking, or crushing of the bronze matrix.

- Contamination-Induced Abrasive Wear: Ingress of dirt, sand, or other hard particles acts as an abrasive, drastically accelerating wear.

- Corrosive Attack: Exposure to chemicals or moisture not compatible with the bronze alloy can lead to pitting and surface degradation.

2.1. The Impact of Operating Conditions on Service Life

The lifespan of a bearing is directly tied to its application's specific parameters. The PV value (Pressure x Velocity) is the most critical factor, but other elements play a significant role.

- PV Value: Operating above the specified PV limit generates excessive heat, which can degrade the solid lubricant and soften the bronze matrix, leading to rapid failure.

- Misalignment: Angular misalignment causes edge loading, creating uneven wear patterns and significantly shortening bearing life.

- Lubricant Compatibility: While self-lubricating, some external contaminants or fluids can wash away the transfer film or react with the embedded lubricants.

3. A Step-by-Step Guide to Bearing Inspection and Assessment

Having a systematic inspection routine is key to reliable maintenance. A common query is a self-lubricating bearing inspection checklist to ensure no critical aspect is overlooked. This step-by-step guide ensures a thorough evaluation, from initial machine observation to post-disassembly analysis.

- Step 1: Operational Monitoring: While the machine is running, listen for unusual noises and use a temperature gun to check for hot spots on the bearing housing.

- Step 2: Shutdown and Lockout/Tagout: Ensure the equipment is safely isolated from all energy sources before beginning any physical inspection.

- Step 3: External Inspection: Look for signs of leakage, debris expulsion, or damage to the bearing housing and seals.

- Step 4: Clearance Measurement: Use a dial gauge to measure radial and axial play, recording the values for comparison with baseline data.

- Step 5: Disassembly and Internal Visual Inspection: Carefully remove the bearing and examine the running surface for wear patterns, scoring, pitting, and the condition of the solid lubricant pockets.

4. Troubleshooting Common Problems: When to Repair vs. Replace

Not every sign of wear necessitates immediate replacement. Effective troubleshooting involves diagnosing the root cause of a problem to decide on the correct course of action. This is where understanding self-lubricating bronze bearing problems and solutions becomes invaluable for minimizing costs and downtime.

- Problem: Gradual Increase in Clearance

- Diagnosis: Normal wear-out over time.

- Solution: Replacement is the only solution once clearances exceed tolerances.

- Problem: Localized Scoring or Grooving

- Diagnosis: Contamination or a damaged shaft.

- Solution: Replace the bearing, inspect and potentially repair or replace the shaft, and improve sealing.

| Observed Problem | Potential Root Cause | Recommended Action |

| Bearing Seizure | Insufficient Clearance, Lubricant Failure, Overload | Replace Bearing, Check Shaft, Review PV Rating |

| Even, Polished Wear | Normal Wear-Out, Abrasive Contaminants | Replace Bearing, Improve Filtration/Sealing |

| Corrosion Pitting | Chemical Attack, Moisture Ingress | Replace with a Corrosion-Resistant Alloy, Improve Seals |

5. The Cost-Benefit Analysis of Proactive Bearing Replacement

A critical business consideration is weighing the cost of a preemptive bearing replacement against the risk and cost of an in-service failure. This analysis, often framed as self-lubricating bronze bearing replacement cost analysis, goes beyond the price of the component itself.

- Cost of Reactive Repair: Includes unplanned downtime, potential damage to more expensive components (shafts, housings, other gears), emergency labor costs, and lost production revenue.

- Cost of Proactive Replacement: Includes the price of the bearing, planned downtime for maintenance, and standard labor costs. This is almost always significantly lower than a reactive repair.

- Benefit of Reliability: Proactive replacement ensures production schedule integrity, maintains product quality, and enhances overall operational safety.

FAQ

What is the most accurate way to check bronze bearing clearance without disassembly?

While a definitive measurement often requires some disassembly, the most accurate non-destructive method for checking clearance is using a dial indicator. The shaft is lifted carefully with a pry bar, and the dial indicator measures the total movement, which corresponds to the radial clearance. For a more advanced approach, ultrasonic testing can estimate wall thickness loss, from which clearance can be inferred if the original dimensions are known. However, for a precise and reliable assessment of how to measure bronze bearing wear accurately, a dial gauge measurement during a scheduled shutdown is the industry-preferred method.

Can a worn self-lubricating bronze bearing be repaired, or must it always be replaced?

In the vast majority of cases, a worn self-lubricating bronze bearing must be replaced. Unlike plain sleeves that can be re-bored, the self-lubricating function depends on the integrity of the embedded solid lubricants within the bronze matrix. Machining the surface would remove these critical lubricant reservoirs, rendering the bearing ineffective. Therefore, replacement is the standard and correct procedure for a worn-out bearing.

How does improper installation shorten the life of a self-lubricating bronze bearing?

Improper installation is a leading cause of premature bearing failure. Common installation errors include using excessive force (hammering directly on the bearing), which can crack or deform the brittle bronze material; misalignment, which causes uneven stress and wear; and incorrect clearance settings. A proper press fit and the use of specialized installation tools are essential to maximize the service life of the new bearing and avoid early replacement.

What are the consequences of running a self-lubricating bearing beyond its recommended clearance limits?

Operating a bearing with excessive clearance leads to a cascade of negative effects. It allows for significant shaft movement, resulting in high-impact loads, increased noise and vibration, and loss of positional accuracy. This abnormal motion accelerates wear on the bearing itself and can lead to fatigue failure of the bearing housing and damage to the shaft. Ultimately, it risks a catastrophic seizure or breakdown, causing far more extensive and expensive damage than a timely bearing replacement would have.

Are there any warning signs that appear long before a self-lubricating bearing completely fails?

Yes, there are several early warning signs. A gradual, steady increase in operating temperature or a slight but persistent change in the machine's sound profile (a developing hum or whine) can be early indicators. A small increase in vibration levels, detectable with a vibration meter, is another key early sign. Implementing a routine condition monitoring program that tracks these parameters (temperature, noise, vibration) is the most effective strategy for detecting problems early and scheduling replacement before a complete failure occurs.