-

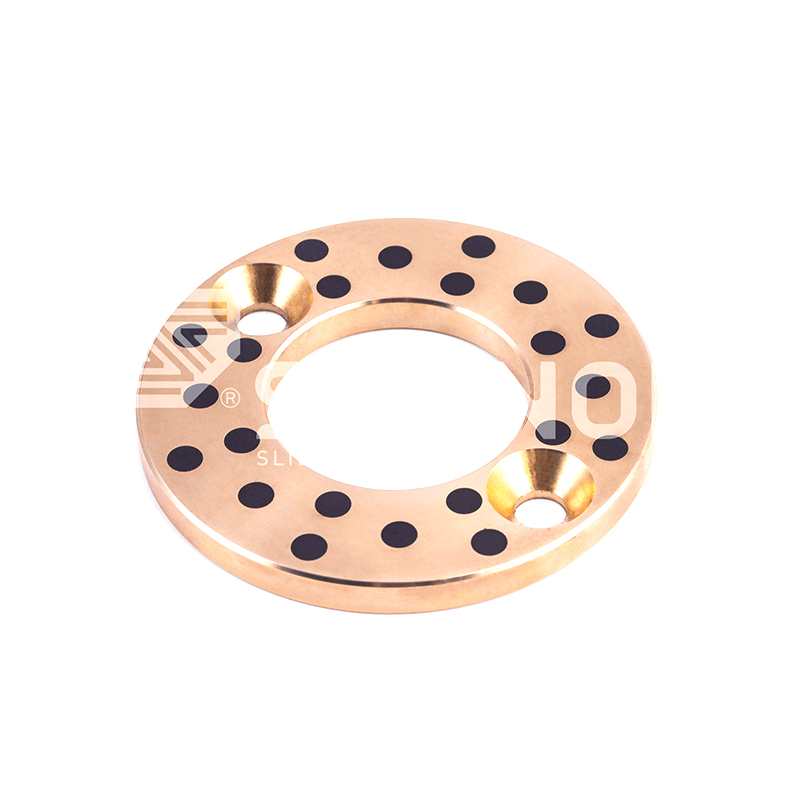

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing -

JDB Solid-lubricating Bearing GB61 Copper NAAMS Standard Flanged Solid-lubricating Bearing

JDB Solid-lubricating Bearing GB61 Copper NAAMS Standard Flanged Solid-lubricating Bearing -

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing -

Oil-retaining Bimetallic Bearing Self-Lubricating 200# P20 Oil-Retaining Steel Bearing Plate - Low Friction Wear-Resistant

Oil-retaining Bimetallic Bearing Self-Lubricating 200# P20 Oil-Retaining Steel Bearing Plate - Low Friction Wear-Resistant -

-

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications -

-

FB090 Bronze Wrapped Bearing FB090 Bronze Wrapped Bearing | Self-Lubricating Bushing & Sleeve

FB090 Bronze Wrapped Bearing FB090 Bronze Wrapped Bearing | Self-Lubricating Bushing & Sleeve

Common Misconceptions about Self-Lubricating Bronze Bearings and Purchasing Recommendations

Industry News-- 1 1. Debunking the "Maintenance-Free" Myth

- 2 2. The Truth About Load Capacity and Speed Limitations

- 3 3. Material Misconceptions: Not All Bronze Bearings Are Created Equal

- 4 4. A Comprehensive Guide to Purchasing the Right Bearing

- 5 5. The Hidden Value of Quality Assurance and Technical Support

- 6 FAQ

- 6.1 Are self-lubricating bronze bearings more expensive than standard bronze bushings?

- 6.2 Can I use a self-lubricating bronze bearing in a food-grade application?

- 6.3 How important is the shaft material and hardness when using self-lubricating bronze bearings?

- 6.4 What is the lead time typically like for custom-sized self-lubricating bronze bearings?

- 6.5 Is it worth paying a premium for a manufacturer that does its own casting?

Self-lubricating bronze bearings are critical components in numerous industrial applications, yet they are often misunderstood. These misconceptions can lead to improper selection, premature failure, and unnecessary costs. Meanwhile, making an informed purchasing decision requires understanding not just the product, but also the manufacturer's capabilities and quality assurance processes. This article aims to demystify self-lubricating bronze bearings by debunking common myths and providing a structured framework for procurement, ensuring you select the right bearing for optimal performance and longevity.

JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing

1. Debunking the "Maintenance-Free" Myth

One of the most prevalent misconceptions is that "maintenance-free" means "attention-free." While self-lubricating bronze bearings do not require periodic re-lubrication with oil or grease, they are not immune to the need for overall maintenance. The term "maintenance-free" specifically refers to the elimination of the lubrication schedule, but it does not absolve the user from other critical maintenance responsibilities. Proper installation, periodic inspection, and environmental control are still essential for maximizing service life.

- Regular Inspection is Still Required: Operators should routinely check for signs of excessive wear, contamination, or damage, even though they don't need to add lubricant.

- Environmental Maintenance: Keeping the operating environment clean to prevent abrasive particles from entering the bearing system is a form of proactive maintenance.

- Monitoring Operational Parameters: Tracking temperature, noise, and vibration levels can provide early warnings of potential issues before they lead to failure.

1.1. What does "maintenance-free" truly mean for bronze bearings?

Understanding the true scope of "maintenance-free self-lubricating bronze bearings" is crucial for setting correct expectations. The embedded solid lubricants within the bronze matrix create a transfer film on the shaft, providing continuous lubrication throughout the bearing's designed lifespan. This eliminates the downtime and labor costs associated with traditional lubrication systems. However, it does not mean the bearing is indestructible or that it can be installed and forgotten.

- Elimination of Lubrication Scheduling: No need for grease guns, oilers, or planned stops for re-lubrication.

- Consistent Performance in Inaccessible Locations: Ideal for applications where bearings are sealed in or difficult to reach after installation.

- Reduced Contamination Risk: Without external lubricants, there is less risk of attracting dirt and dust that can form a grinding paste.

2. The Truth About Load Capacity and Speed Limitations

Another common area of confusion revolves around the performance boundaries of these bearings. Some users mistakenly believe that because they are self-lubricating, they can handle infinitely high loads or speeds. In reality, all bearings have specific operational envelopes defined by their material properties and design. The PV value (Pressure x Velocity) is the key parameter that defines the safe operating window for a self-lubricating bronze bearing.

- PV Value is Paramount: Exceeding the manufacturer's specified PV limit generates excessive heat, which can degrade the solid lubricant and lead to rapid failure.

- High Load vs. High Speed: These bearings are generally better suited for high-load, low-speed applications or low-load, high-speed applications, but rarely both simultaneously.

- Impact of Lubricant Type: The choice of solid lubricant (e.g., graphite vs. PTFE) directly influences the maximum permissible PV value and operating temperature.

3. Material Misconceptions: Not All Bronze Bearings Are Created Equal

The term "bronze" encompasses a family of copper-based alloys with significantly different properties. A major pitfall for buyers is self-lubricating bronze bearing material selection mistakes, such as assuming all bronze bearings are interchangeable. The specific alloy composition and manufacturing process drastically affect performance in areas like strength, corrosion resistance, and compatibility with embedded lubricants.

- Tin Bronze vs. Aluminum Bronze: Tin bronze offers excellent machinability and corrosion resistance, while aluminum bronze provides higher strength and better wear resistance under heavy loads.

- The Role of Manufacturing Process: Centrifugal casting produces a denser, stronger structure with a consistent grain flow, ideal for high-load applications, whereas sintered powders may be more suitable for high-volume, lower-duty parts.

- Importance of Lubricant Integration: The method of incorporating the solid lubricant (e.g., plugged, woven, or sintered) affects its release rate and the overall lifespan of the bearing.

| Bronze Alloy Type | Key Advantages | Ideal Applications |

| Tin Bronze | Excellent corrosion resistance, good machinability | Marine environments, water pumps, general industry |

| Aluminum Bronze | High strength, excellent wear and shock load resistance | Heavy machinery, mining equipment, steel mills |

| Manganese Bronze | High tensile strength and good corrosion resistance | Gears, nuts, valve components |

4. A Comprehensive Guide to Purchasing the Right Bearing

Navigating the procurement process for self-lubricating bronze bearings requires a systematic approach to avoid costly errors. A well-structured self-lubricating bronze bearing purchasing guide should focus on defining application requirements first, then matching those needs to a manufacturer's technical capabilities and quality standards. This ensures the selected bearing will perform reliably in its intended environment.

- Step 1: Define Application Parameters: Clearly document the load (static and dynamic), speed, operating temperature, environmental conditions (presence of chemicals, water, dust), and the type of motion (continuous, oscillating, intermittent).

- Step 2: Select the Appropriate Material and Lubricant: Based on the parameters from Step 1, choose the bronze alloy and solid lubricant combination that best suits the application's demands.

- Step 3: Evaluate Manufacturer Capabilities: Assess the supplier's expertise, manufacturing processes, quality control measures, and ability to provide technical support and customization.

- Step 4: Request and Review Documentation: Ask for material certifications, test reports, and dimensional inspection reports to verify the product meets your specifications.

4.1. Key questions to ask a bronze bearing supplier

Engaging in a technical dialogue with a potential supplier is one of the most effective ways to gauge their expertise and product quality. Knowing the key questions to ask a bronze bearing supplier can help you differentiate between a simple parts vendor and a true technical partner capable of providing a reliable, application-optimized solution.

- What is your in-house material production capability? A manufacturer that controls its casting, like Zhejiang Shuangnuo Bearing Technology Co., Ltd., can ensure quality from the source.

- Can you provide spectrographic analysis reports for the material? This confirms the chemical composition of the bronze alloy meets the required standard.

- What is your process for ensuring the consistency of the embedded lubricant? This speaks to the homogeneity and reliability of the self-lubricating function.

- Do you offer custom design and engineering support? This is crucial for non-standard applications that require a tailored solution.

5. The Hidden Value of Quality Assurance and Technical Support

The initial purchase price of a bearing is often a small fraction of the total cost of ownership, which includes downtime, labor for replacement, and potential damage to adjacent components. Therefore, the value provided by a manufacturer's rigorous quality assurance and technical support cannot be overstated. A supplier that invests in comprehensive testing and expert engineering support ultimately delivers greater long-term value and reliability.

- In-Process Quality Control: Look for suppliers who monitor the entire production process, from raw material to finished product, rather than just performing a final inspection.

- Third-Party Validation: Suppliers who regularly commission national testing agencies to verify material composition and mechanical properties provide an extra layer of credibility.

- Integrated Production: A manufacturer with control over the entire production chain, from casting to CNC machining, can ensure tighter tolerances, shorter lead times, and better overall consistency.

FAQ

Are self-lubricating bronze bearings more expensive than standard bronze bushings?

Initially, yes, self-lubricating bronze bearings typically have a higher unit cost than standard bronze bushings due to the more complex manufacturing process involved in integrating the solid lubricants. However, a true cost analysis must consider the Total Cost of Ownership (TCO). By eliminating lubrication systems, reducing maintenance labor, preventing contamination, and often providing a longer service life, self-lubricating bearings frequently prove to be more cost-effective in the long run, making them a smart investment for many applications.

Can I use a self-lubricating bronze bearing in a food-grade application?

Yes, but with critical stipulations. Not all self-lubricating bronze bearings are suitable for food-grade applications. The bearing must use an approved solid lubricant, such as PTFE or other FDA-compliant polymers, and the bronze alloy itself must also be suitable for food contact. It is essential to work with a supplier who can provide explicit documentation and certifications confirming that both the base material and the lubricant meet the relevant food safety standards (e.g., FDA, USDA, EU 1935/2004) for your specific region and application.

How important is the shaft material and hardness when using self-lubricating bronze bearings?

Extremely important. The shaft is an integral part of the bearing system. A hard, smooth, and ground shaft surface (typically hardened steel with a hardness of 45-55 HRC) is highly recommended. A soft or rough shaft will wear rapidly and can also cause accelerated wear of the bearing surface by preventing the formation of a stable transfer film. The compatibility and surface finish of the shaft are as critical as the bearing selection itself for achieving the promised performance and lifespan.

What is the lead time typically like for custom-sized self-lubricating bronze bearings?

Lead times for custom bearings can vary significantly based on the manufacturer's capabilities. For a manufacturer with an integrated production process, like Zhejiang Shuangnuo Bearing Technology Co., Ltd., which controls everything from raw material casting to final CNC machining, lead times can be optimized. While standard parts may be available quickly, custom sizes might take several weeks. The complexity of the design, the specific material required, and the supplier's current production schedule all factor in. It's always best to discuss your timeline early in the procurement process with your supplier.

In most cases, yes, paying a slight premium for a manufacturer that controls its own casting process is a worthwhile investment. In-house casting, especially using advanced methods like centrifugal casting, allows for superior control over material quality, density, and homogeneity. This results in a bearing with more consistent mechanical properties, fewer internal defects, and ultimately, higher reliability and performance. This vertical integration is a strong indicator of a supplier committed to quality from the source, which mitigates the risk of bearing failure in your equipment.