-

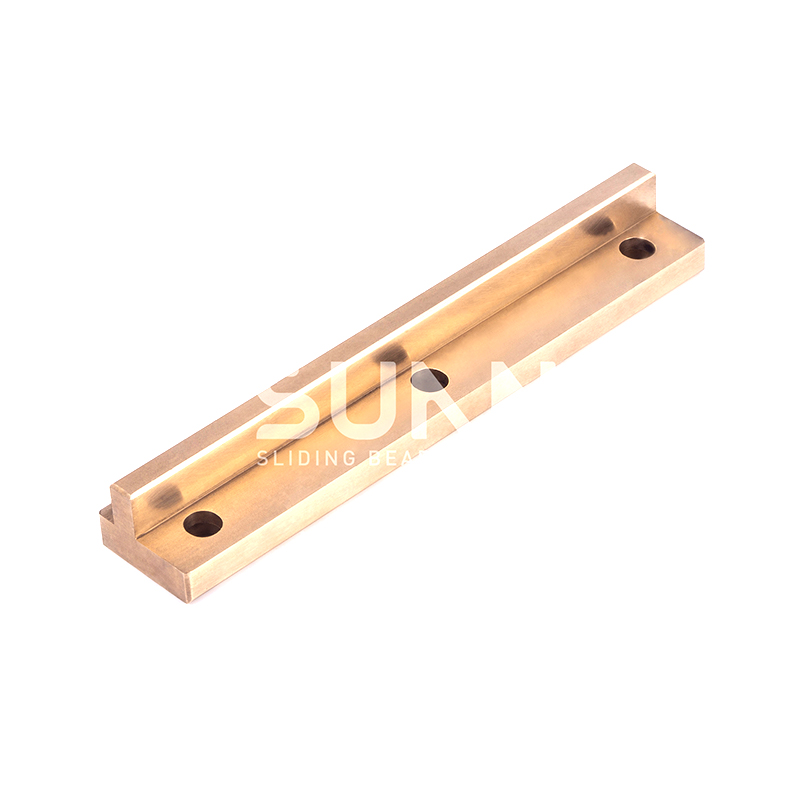

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components -

JDB Solid-lubricating Bearing JDB-5 Steel Embedded Wear Resistant Solid-lubricating Bearing

JDB Solid-lubricating Bearing JDB-5 Steel Embedded Wear Resistant Solid-lubricating Bearing -

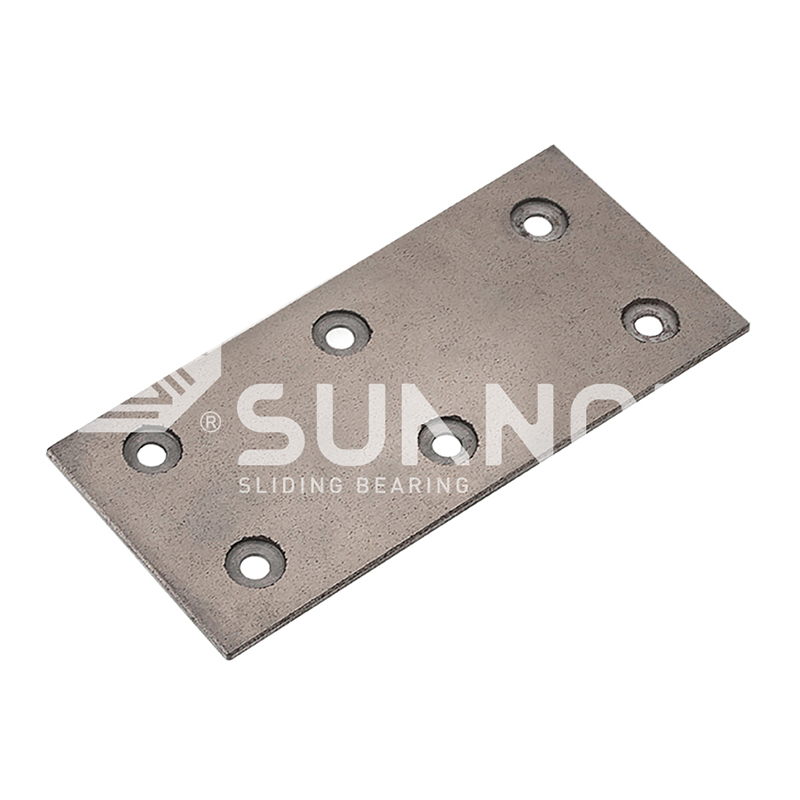

Oil-retaining Bimetallic Bearing Self-Lubricating 200# P20 Oil-Retaining Steel Bearing Plate - Low Friction Wear-Resistant

Oil-retaining Bimetallic Bearing Self-Lubricating 200# P20 Oil-Retaining Steel Bearing Plate - Low Friction Wear-Resistant -

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface -

-

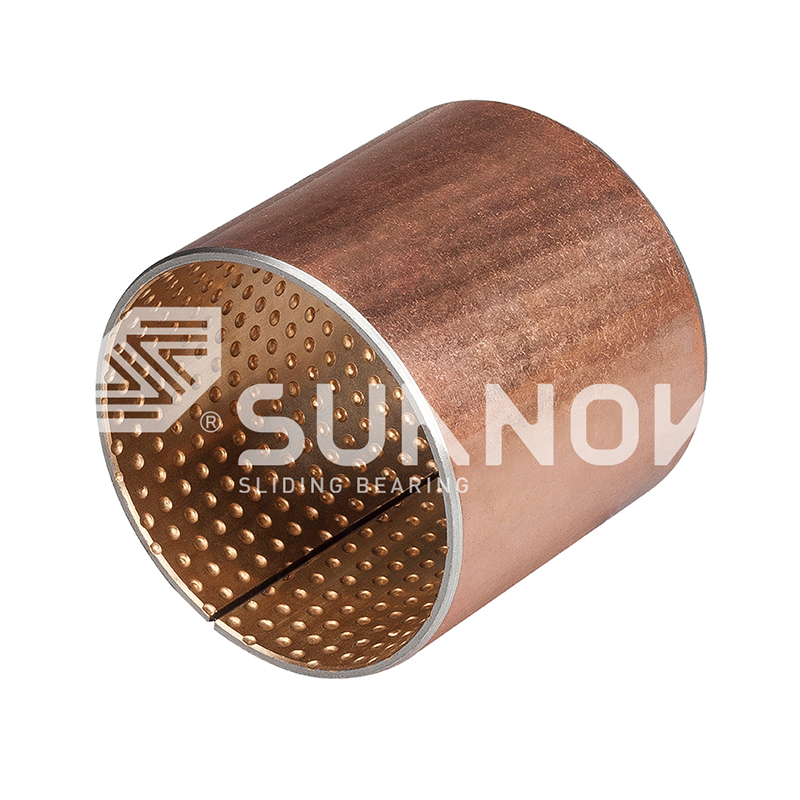

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications -

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing -

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

A Detailed Explanation of the Friction and Wear Resistance of Self-Lubricating Bronze Bearings

Industry News-- 1 1. The Fundamental Mechanism Behind Self-Lubrication in Bronze Bearings

- 2

- 3 2. Key Factors Influencing the Wear Resistance of Self-Lubricating Bronze Bearings

- 4 3. Advantages of Using Self-Lubricating Bronze Bearings in High-Load Applications

- 5 4. Comparing Graphite vs. PTFE in Self-Lubricating Bronze Bearings

- 6 5. Maintenance and Failure Analysis for Self-Lubricating Bronze Bushings

- 7 FAQ

- 7.1 What is the typical lifespan of a self-lubricating bronze bearing?

- 7.2 Can self-lubricating bronze bearings be used in water or underwater applications?

- 7.3 How does the PV rating affect the selection of a self-lubricating bearing?

- 7.4 Are self-lubricating bronze bearings suitable for high-temperature environments?

- 7.5 What is the difference between sintered and cast self-lubricating bronze bearings?

Self-lubricating bronze bearings represent a significant advancement in bearing technology, offering exceptional performance in demanding applications where conventional lubrication is impractical. These specialized components integrate solid lubricants within the bronze matrix, creating a durable, maintenance-free solution that reduces friction and wear. This article provides an in-depth analysis of the friction and wear resistance mechanisms of self-lubricating bronze bearings, exploring their material composition, operational advantages, and ideal applications. Understanding these factors is crucial for engineers and designers seeking to optimize machinery performance and longevity.

1. The Fundamental Mechanism Behind Self-Lubrication in Bronze Bearings

The core principle of self-lubrication in bronze bearings hinges on the strategic embedding of solid lubricants within a strong metallic matrix. Typically, a bronze alloy (such as tin bronze or aluminum bronze) forms the structural backbone, providing high load-bearing capacity and thermal conductivity. Within this matrix, materials like graphite, PTFE, or other polymers are uniformly distributed. During operation, as friction occurs, a thin, continuous film of these lubricants is transferred to the opposing surface, drastically reducing the coefficient of friction. This process ensures consistent lubrication without the need for external oil or grease.

- Continuous Lubricant Film: The solid lubricants embedded in the bearing surface are smeared onto the shaft, forming a protective layer that separates the two metal surfaces and minimizes direct metal-to-metal contact.

- Embedded Lubricant Reservoirs: The bronze matrix acts as a reservoir, steadily supplying lubricant to the bearing surface over its entire operational lifespan, even in high-load or low-speed scenarios.

- Thermal Management: The bronze alloy effectively dissipates heat generated by friction, preventing the degradation of the solid lubricants and maintaining the integrity of the lubricating film.

1.1. Material Composition and Its Role

The specific composition of the bronze alloy and the choice of solid lubricant are critical in determining the bearing's overall performance. Manufacturers like Zhejiang Shuangnuo Bearing Technology Co., Ltd. utilize processes like centrifugal casting and sintering to achieve a homogenous microstructure, ensuring the lubricants are evenly distributed for consistent performance. The material selection directly influences key properties such as compressive strength, thermal conductivity, and the rate of lubricant release.

- Bronze Alloy Matrix: Common alloys include tin bronze (known for its corrosion resistance) and aluminum bronze (valued for higher strength). The alloy provides the structural support and heat dissipation necessary for the system to function.

- Solid Lubricants: Graphite is widely used for its stability at high temperatures, while PTFE offers an extremely low coefficient of friction. The choice depends on the application's specific environmental and operational demands.

| Material Component | Primary Function | Key Characteristic |

| Tin Bronze Matrix | Structural Support & Load Capacity | Excellent corrosion resistance and conformability |

| Graphite Lubricant | High-Temperature Lubrication | Stable up to 500°C in non-oxidizing atmospheres |

| PTFE Lubricant | Ultra-Low Friction | Very low coefficient of friction, suitable for food-grade applications |

GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing

2. Key Factors Influencing the Wear Resistance of Self-Lubricating Bronze Bearings

Wear resistance is a paramount characteristic that defines the service life of a bearing. For self-lubricating bronze bearings, wear resistance is not a single property but a system characteristic resulting from the interplay between the bronze matrix, the solid lubricants, and the operating environment. Superior wear resistance ensures extended component life, reduced downtime, and lower total cost of ownership.

- Matrix Hardness and Density: A denser, harder bronze matrix better resists deformation and abrasive wear. Advanced casting techniques are employed to minimize porosity and create a robust structure.

- Lubricant Type and Percentage: The volume and type of solid lubricant affect the formation and durability of the lubricating film. An optimal balance is required to provide sufficient lubrication without compromising the matrix's structural integrity.

- Operating PV Value (Pressure x Velocity): Staying within the recommended PV limit for the specific bearing material is critical. Exceeding this limit can cause rapid wear and premature failure.

2.1. How to improve bronze bearing wear life

Extending the wear life of a bronze bearing involves both proper selection and optimal operating conditions. A common query from engineers is how to improve bronze bearing wear life. The answer lies in a multi-faceted approach that considers design, installation, and maintenance practices. By addressing these factors, users can significantly enhance performance and reliability.

- Proper Shaft Hardness and Finish: A hard, smooth shaft surface (often hardened steel) minimizes abrasive wear on the softer bearing surface.

- Adequate Clearance: Providing the correct radial clearance accommodates thermal expansion and misalignment, preventing edge loading and excessive wear.

- Clean Operating Environment: Preventing the ingress of abrasive contaminants is one of the most effective ways to prolong bearing life. Seals or shields may be necessary in dirty environments.

3. Advantages of Using Self-Lubricating Bronze Bearings in High-Load Applications

One of the most compelling reasons to choose these bearings is their performance under extreme pressure. The question of self-lubricating bronze bearing advantages high load is central to their application in heavy machinery, construction equipment, and industrial automation. Their unique construction allows them to withstand significant static and dynamic loads without failure.

- High Compressive Strength: The bronze matrix provides excellent load-carrying capacity, making them suitable for supporting heavy weights and shock loads.

- Maintenance-Free Operation: The built-in lubrication system eliminates the need for periodic re-lubrication, reducing maintenance costs and preventing lubrication-related failures.

- Performance in Boundary Lubrication Conditions: They perform exceptionally well in situations where forming a full fluid film is impossible, such as during start-up, slow oscillations, or high-load, low-speed operations.

4. Comparing Graphite vs. PTFE in Self-Lubricating Bronze Bearings

The choice between graphite and PTFE as the solid lubricant is a critical design decision. A frequent technical comparison revolves around graphite vs PTFE self-lubricating bronze bearings. Each lubricant offers a distinct set of properties that make it suitable for different operational environments and requirements.

- Graphite: Excels in high-temperature applications and provides good electrical conductivity. It is less effective in very dry or vacuum environments where a gaseous film cannot form.

- PTFE (Polytetrafluoroethylene): Offers an extremely low coefficient of friction and is chemically inert. It is ideal for applications requiring ultra-smooth motion or where contamination from lubricants is a concern, such as in food processing or pharmaceutical machinery.

| Parameter | Graphite-Based Bearings | PTFE-Based Bearings |

| Max Operating Temperature | ~350°C (in air) | ~250°C |

| Coefficient of Friction | Low | Extremely Low |

| Chemical Resistance | Good | Excellent |

| Ideal For | High-temperature, general industrial use | Food-grade, chemical, and clean applications |

5. Maintenance and Failure Analysis for Self-Lubricating Bronze Bushings

While designed to be maintenance-free, understanding potential failure modes is essential for predictive maintenance and troubleshooting. A search for self-lubricating bronze bushing maintenance failure analysis often stems from a need to diagnose issues and prevent recurrence. Common failure modes include excessive wear, seizure, and pitting, each with identifiable root causes.

- Overload: Exceeding the dynamic or static load capacity can lead to plastic deformation of the bronze matrix, crushing the bearing.

- Contamination: Dirt and abrasive particles can become embedded in the soft bearing surface, acting as a grinding paste that accelerates wear on both the bearing and the shaft.

- Insufficient Lubricant Film: In some cases, if the operating conditions do not allow for the proper transfer of the solid lubricant to the shaft, premature wear can occur.

5.1. Common Failure Modes and Solutions

A systematic approach to failure analysis can help identify the root cause and implement corrective actions. This involves examining the failed component and the operating conditions.

- Failure Mode: Adhesive Wear (Seizure)

- Symptoms: Bearing material is transferred to the shaft, resulting in galling and eventual locking.

- Probable Causes: Inadequate clearance, overload, insufficient lubricant film formation.

- Solutions: Increase shaft hardness, ensure proper installation clearance, verify the PV value is within limits.

- Failure Mode: Abrasive Wear

- Symptoms: Scratches and grooves on the bearing surface and shaft.

- Probable Causes: Contaminated environment, inadequate sealing, poor shaft surface finish.

- Solutions: Improve sealing, implement filtration, specify a finer shaft surface finish.

FAQ

What is the typical lifespan of a self-lubricating bronze bearing?

The lifespan of a self-lubricating bronze bearing is not a fixed value but is highly dependent on the application's operating conditions. Key factors include the load (P), speed (V), operating temperature, presence of contaminants, and alignment. Under ideal conditions within their specified PV limit, these bearings can last for tens of thousands of hours, often outlasting the equipment they are installed in. For a precise estimate, it is best to consult with a technical expert from a manufacturer like Zhejiang Shuangnuo Bearing Technology Co., Ltd., who can perform a lifecycle analysis based on your specific parameters.

Can self-lubricating bronze bearings be used in water or underwater applications?

Yes, certain types of self-lubricating bronze bearings are well-suited for water and underwater applications. Bronze alloys, particularly tin bronze, offer excellent corrosion resistance in fresh and salt water. The solid lubricants, such as PTFE or special polymer blends, are not washed away by water, ensuring continuous lubrication. This makes them ideal for use in marine equipment, water pumps, hydraulic systems, and sluice gates. It is crucial to select the correct material combination to prevent galvanic corrosion when paired with a specific shaft material.

How does the PV rating affect the selection of a self-lubricating bearing?

The PV rating (Pressure x Velocity) is a fundamental engineering parameter used to select and size self-lubricating bearings. The pressure (P) is the load divided by the projected bearing area, and the velocity (V) is the surface speed of the shaft. Multiplying these values gives the PV value, which represents the bearing's internal heat generation. Selecting a bearing with a maximum PV rating higher than your application's calculated value is essential to prevent overheating, rapid wear, and failure. Operating below the maximum PV limit ensures a stable lubricating film and a long service life.

Are self-lubricating bronze bearings suitable for high-temperature environments?

The suitability for high-temperature environments depends primarily on the type of solid lubricant used. Graphite-based self-lubricating bronze bearings can operate effectively at temperatures up to 350°C in air, as graphite retains its lubricity at high heat. However, the strength of the bronze matrix decreases as temperature rises, which must be accounted for in load calculations. PTFE-based bearings have a lower maximum operating temperature, typically around 250°C. For extreme temperatures, it is critical to consult the manufacturer's datasheets and select a bearing grade specifically designed for those conditions.

What is the difference between sintered and cast self-lubricating bronze bearings?

The primary difference lies in the manufacturing process, which influences the material's microstructure and performance. Sintered bronze bearings are made by compacting bronze powder and sintering it in a furnace, creating a porous structure that can be impregnated with oil or other lubricants. They are typically used for lower-load, high-volume applications. Cast self-lubricating bearings, such as those produced by Zhejiang Shuangnuo Bearing Technology Co., Ltd. using centrifugal or continuous casting, have a denser, non-porous structure with solid lubricants (like graphite plugs) mechanically embedded within the bronze matrix. This results in higher mechanical strength, better impact resistance, and a longer service life, making them suitable for heavy-duty and high-load applications.