-

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing -

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing -

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery -

JF-800 Bi-metal Bearing JF-750 Self-Lubricating Lead Free Bi-Metal Bearing for Heavy Duty Engines Low Friction

JF-800 Bi-metal Bearing JF-750 Self-Lubricating Lead Free Bi-Metal Bearing for Heavy Duty Engines Low Friction -

-

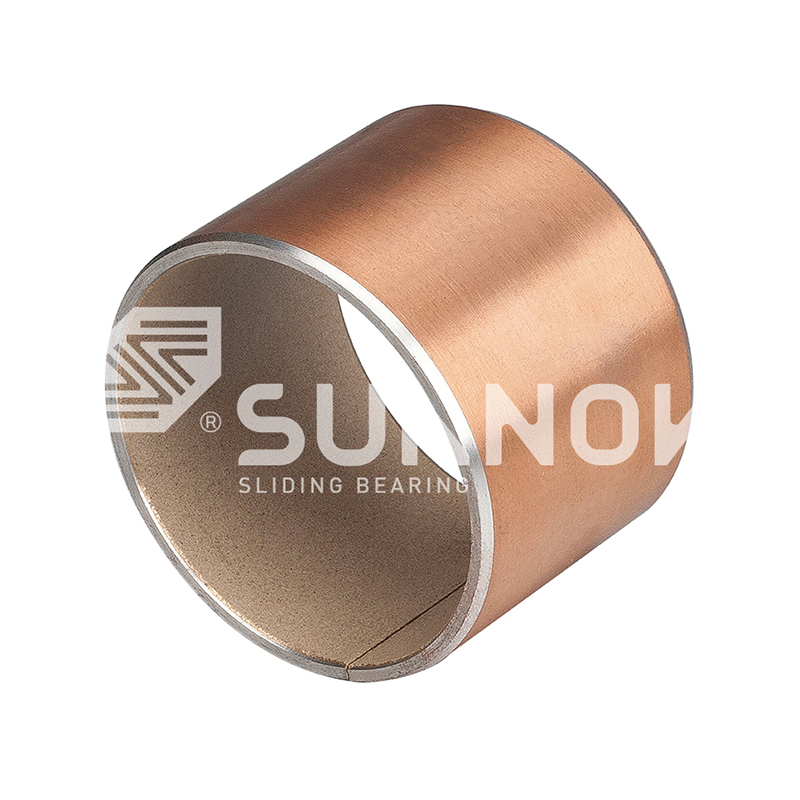

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing -

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

How Does a Bronze graphite bearing Maintain Consistent Self-Lubrication in Extreme High-Temperature Environments?

Industry News-In heavy industrial applications where liquid lubricants vaporize or carbonize, the Bronze graphite bearing stands as a critical engineering solution. These bearings are designed to operate in environments where traditional grease or oil lubrication is physically impossible due to extreme heat, vacuum, or high-load conditions. Zhejiang Shuangnuo Bearing Technology Co., Ltd. has spent nearly a decade perfecting the research and production of these specialized components. By utilizing advanced processes such as centrifugal casting and metal mold casting, we ensure the material integrity of our copper alloys from the source, providing integrated solutions that range from raw material casting to high-precision CNC machining.

The Mechanism of Solid Lubricant Transfer

The core functionality of high temperature self lubricating bronze bearings lies in the synergy between the bronze matrix and the embedded solid lubricant. Unlike standard bearings that require an external oil film, these bearings feature "plugged" graphite reservoirs. As the shaft rotates, the friction generates a microscopic amount of heat and mechanical shear, which draws the graphite from its pockets and spreads it across the bearing surface. This creates a tenacious "transfer film" that prevents metal-to-metal contact even when temperatures exceed 300°C.

Comparing Material Stability: Bronze vs. Steel at High Temperatures

Standard steel bearings undergo significant hardness loss and thermal expansion at elevated temperatures, leading to seizure. In contrast, specialized bronze alloys used in solid lubricant embedded bronze bushings maintain their structural load-bearing capacity while the graphite provides a constant friction-reducing barrier. This makes them ideal for furnace components, kilns, and metallurgical equipment.

| Feature | Standard Grease-Lubricated Bearing | Bronze Graphite Bearing |

| Lubricant Threshold | Fails as oil evaporates (approx. 150°C - 200°C). | Stable up to 400°C or higher depending on alloy. |

| Maintenance Requirement | Frequent relubrication cycles needed. | Completely maintenance-free throughout its life. |

| Load Capacity | Limited by the strength of the oil film. | High; supported by a solid metal matrix. |

Advanced Casting and Spectrometric Analysis

The reliability of a Bronze graphite bearing starts in the furnace. At Zhejiang Shuangnuo, we monitor the entire process with spectrometer testing before, during, and after casting to confirm precise material composition. This technical rigor ensures that the bronze matrix possesses the correct mechanical properties to hold the graphite plugs securely. According to the 2024 Global Industrial Fastener and Bearing Standards, the demand for self-lubricating materials in high-heat sectors is projected to rise significantly as manufacturers seek to reduce downtime in energy-intensive processes.

Source: ISO 4382-1:2024 Plain Bearings - Copper Alloys for Solid Bushings

Engineering custom graphite plugged bronze bearing manufacturing

Not every high-temperature environment is the same. Through custom graphite plugged bronze bearing manufacturing, engineers can specify the layout and volume of graphite based on the oscillation speed and load. Our machining centers, equipped with more than 80 sets of CNC machine tools, allow for the creation of intricate lubrication patterns that optimize film transfer for personalized application characteristics.

Thermal Expansion and Load-Bearing Capacity

In extreme heat, the coefficient of thermal expansion (CTE) becomes a critical design factor. Wear resistant bronze graphite flange bearings are engineered with specific clearance tolerances to account for material growth. The solid inlaid technology ensures that as the temperature rises, the lubricant remains trapped in the matrix rather than being squeezed out, which is a common failure mode in bimetallic sintered bearings. Technical breakthroughs in 2025 have improved the adhesion of transfer films in vacuum environments, further expanding the utility of these components in aerospace and semiconductor manufacturing.

Source: ASTM B438: Standard Specification for Bronze-Base Powder Metallurgy Bearings 2025 Revision

Comparative Performance: Sintered Bimetal vs. Solid Inlaid Bronze

While sintered bimetal products are excellent for mid-range loads and speeds, solid inlaid Bronze graphite bearing products offer significantly higher wear resistance under heavy static loads and slow, intermittent movements.

| Property | Sintered Bimetal Product | Solid Inlaid Bronze Bearing |

| Static Load Rating | Moderate (approx. 100 N/mm²). | High (up to 250 N/mm² depending on alloy). |

| Operating Temperature | Best under 250°C. | Superior performance up to 400°C+. |

| Lubrication Mode | Oil-impregnated pores. | Solid inlaid graphite plugs. |

Operational Advantages for B2B Procurement

For B2B buyers and wholesalers, the value proposition of maintenance free bronze graphite bearings for industry lies in the dramatic reduction of the total cost of ownership (TCO). By eliminating the need for automated lubrication systems and manual grease application, facilities can achieve longer MTBF (Mean Time Between Failures). Zhejiang Shuangnuo provides authoritative test reports from national testing agencies to verify the mechanical properties and material composition of our products, ensuring transparency and trust in every shipment.

Conclusion: The Future of Self-Lubricating Technology

The Bronze graphite bearing is an essential component for the next generation of high-temperature industrial machinery. By controlling the production from raw material casting to finished part processing, Zhejiang Shuangnuo Bearing Technology Co., Ltd. ensures that every bearing provides consistent self-lubrication under the most punishing conditions. Whether you require standard tin bronze bushings or a custom graphite plugged bronze bearing manufacturing solution, our technical expertise and strong production capacity ensure first-class service and professional application solutions.

Frequently Asked Questions (FAQ)

- What is the maximum temperature a Bronze graphite bearing can handle? Depending on the base alloy (like aluminum bronze or tin bronze), these bearings can typically operate between 300°C and 450°C without lubrication failure.

- Can these bearings operate under water? Yes, the solid lubricant is not affected by water, making solid lubricant embedded bronze bushings excellent for hydro-power and marine applications.

- Are maintenance free bronze graphite bearings for industry really maintenance-free? Yes, because the lubricant is embedded within the metal matrix, it is continuously supplied to the surface throughout the entire wear life of the bearing.

- What casting processes do you use? We utilize centrifugal casting, continuous casting, and metal mold casting to ensure the highest density and strength for the bronze matrix.

- How do wear resistant bronze graphite flange bearings handle axial loads? The flange design provides a secondary thrust surface that is also embedded with graphite plugs, allowing the bearing to handle both radial and axial loads simultaneously.