-

JDB Solid-lubricating Bearing JDB650 Self-Lubricating Brass Bushing Oilless Bearings

JDB Solid-lubricating Bearing JDB650 Self-Lubricating Brass Bushing Oilless Bearings -

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing -

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing -

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing -

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed)

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed) -

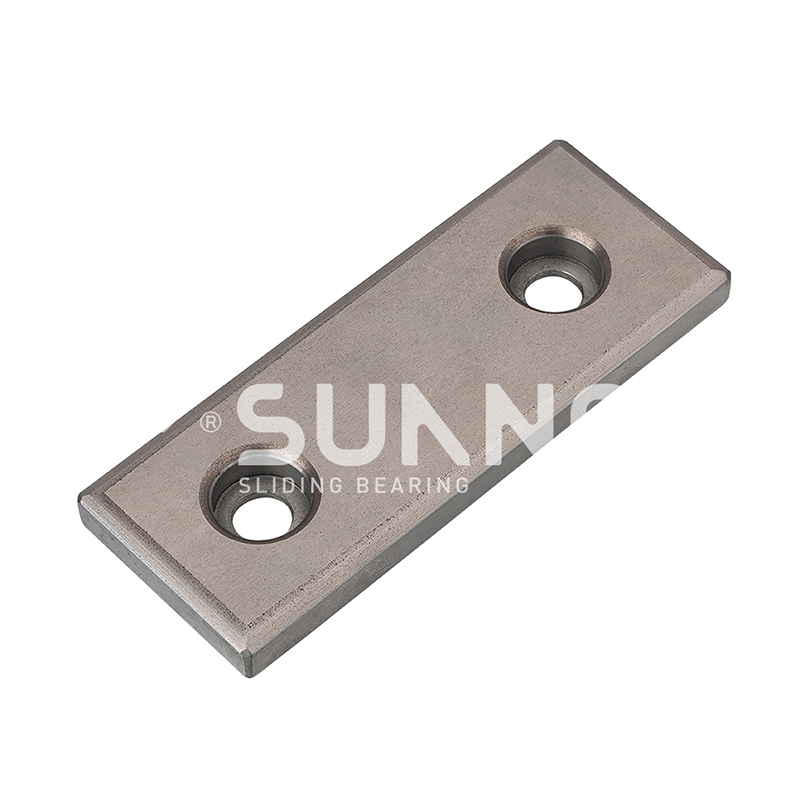

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications -

-

FB090 Bronze Wrapped Bearing FB091 High-Performance Copper Wrapped Bearing & Bushing | Bronze Bush

FB090 Bronze Wrapped Bearing FB091 High-Performance Copper Wrapped Bearing & Bushing | Bronze Bush

How to Accurately Calculate the Wear Life of a Self Lubrication Bearing in High-Load Applications

Industry News-- 1 The Fundamental PV Value Calculation for Bearing Life

- 2 Determining Wear Depth Through Empirical Modeling

- 3 Environmental and Application-Specific Adjustment Factors

- 4 Frequently Asked Questions (FAQ)

- 4.1 1. What is the maximum load a self lubrication bearing can handle?

- 4.2 2. Can these bearings operate in submerged or wet conditions?

- 4.3 3. How do graphite plugs work to extend wear life?

- 4.4 4. Why is the PV value so important in life calculation?

- 4.5 5. Do I need to lubricate these bearings during installation?

In the field of heavy-duty mechanical engineering, the reliability of a self lubrication bearing is critical for minimizing downtime and maintenance costs. Unlike traditional bearings that require manual grease injection, these advanced components rely on an internal lubricant reservoir—typically graphite or PTFE—to maintain a low-friction interface. Zhejiang Shuangnuo Bearing Technology Co., Ltd., a high-tech manufacturer with nearly 10 years of R&D experience, specializes in the centrifugal casting of copper alloys and the precision machining of solid inlaid products. By integrating independent raw material casting with over 80 sets of CNC equipment, we provide professional application solutions, including solid lubricant embedded bushings for mining equipment and customized components designed to survive the most punishing industrial environments.

The Fundamental PV Value Calculation for Bearing Life

The wear life of a self lubrication bearing is primarily determined by its PV value, which represents the product of the specific load () and the sliding velocity (). In high-load applications, the specific load often approaches the material's elastic limit, making accurate calculation essential to prevent premature seizure. According to the ISO 4382-1:2024 standards for plain bearings, the "permissible PV" is a dynamic threshold influenced by the heat dissipation capacity of the housing and the coefficient of friction. While standard bronze bushings have moderate PV limits, graphite plugged bronze bearings for high temperature environments are engineered to maintain a stable lubricating film even when thermal expansion narrows the clearance, effectively extending the operational life beyond traditional limits.

Source: ISO 4382-1:2024 Plain Bearings — Copper Alloys

Comparison: Standard Lubricated vs. Self-Lubricated Wear Profiles

Traditional bearings exhibit high initial wear until a grease film is established, whereas self lubrication bearing technology provides a more linear and predictable wear rate throughout its lifecycle.

| Performance Metric | Grease-Lubricated Bronze Bushing | Solid Inlaid self lubrication bearing |

| Maintenance Frequency | High (Frequent re-greasing required) | Zero (Maintenance-free operation) |

| Wear Consistency | Variable (Depends on lubrication intervals) | Stable (Linear wear over time) |

| High-Load Stability | Prone to film rupture | Superior (Solid lubricant resists squeezing) |

| Environmental Tolerance | Sensitive to dust and grit | Excellent (Self-cleaning property) |

Determining Wear Depth Through Empirical Modeling

Engineers must calculate the "radial wear depth" to determine when a bearing has reached its end-of-service life. The calculation typically follows the formula: , where is wear depth, is the wear factor, and is time. Selecting a heavy duty bimetallic bearing for construction machinery requires a specific -factor that accounts for shock loads and abrasive particles. Recent technical data from the 2025 Global Tribology Report by the STLE (Society of Tribologists and Lubrication Engineers) indicates that bimetallic sintered structures can reduce the wear factor by up to 25% compared to monolithic alloys due to the improved grain structure achieved through sintering. This reduction in directly translates to a longer service interval for maintenance free flange bearings for solar trackers and other oscillating high-load systems.

Source: STLE - Society of Tribologists and Lubrication Engineers: 2025 Research Trends

Comparison: Bimetallic vs. Monometallic Performance

Bimetallic bearings offer a higher load-carrying capacity at a lower thickness, while monometallic copper alloys provide superior corrosion resistance and overall structural toughness.

| Technical Detail | Monolithic Copper Alloy (Centrifugal Cast) | Heavy duty bimetallic bearing for construction machinery |

| Load Capacity | Up to 100 N/mm² | Up to 150+ N/mm² (Steel backed) |

| Shock Resistance | Excellent (Ductile material) | Good (Rigid support) |

| Cost-Effectiveness | Higher (Material volume dependent) | Lower (Reduced alloy content) |

| Application Suitability | Heavy mining, large valves | Engine components, hydraulic cylinders |

Environmental and Application-Specific Adjustment Factors

The theoretical wear life must be adjusted by factors such as surface roughness, shaft hardness, and operating temperature. For instance, solid lubricant embedded bushings for mining equipment must operate in environments where moisture and grit are prevalent. If the mating shaft is not hardened to at least HRC 50, the wear rate of the bearing will accelerate significantly. At Zhejiang Shuangnuo, we use spectrometer testing three times during the furnace process to ensure our copper alloy base (brass, aluminum bronze, or tin bronze) achieves the exact mechanical properties required to support these adjustment factors. By providing a customized oiles bearing for chemical industry valves, we can adjust the alloy composition to resist acidic corrosion, which would otherwise degrade the bearing surface and cause an exponential spike in the wear rate.

- Shaft Hardness: Recommend HRC 50-60 to minimize abrasive wear.

- Surface Finish: Target Ra 0.2 to 0.8 μm for the mating shaft to ensure film transfer.

- Temperature Correction: Utilize graphite plugged bronze bearings for high temperature for operations exceeding 150°C.

- Load Character: Adjust life expectancy for intermittent vs. continuous loading cycles.

Frequently Asked Questions (FAQ)

1. What is the maximum load a self lubrication bearing can handle?

Depending on the alloy, a self lubrication bearing can handle static loads up to 250 N/mm² and dynamic loads up to 100 N/mm². High-load applications often utilize heavy duty bimetallic bearing for construction machinery to maximize strength.

2. Can these bearings operate in submerged or wet conditions?

Yes. Our customized oiles bearing for chemical industry valves is designed with alloys and lubricants that resist water washout, making them ideal for hydropower and offshore applications.

3. How do graphite plugs work to extend wear life?

In graphite plugged bronze bearings for high temperature, the graphite is released onto the friction surface as the shaft rotates, creating a solid lubricating film that prevents metal-to-metal contact even under high heat.

4. Why is the PV value so important in life calculation?

The PV value determines the heat generated at the bearing interface. If the PV exceeds the material's limit, the self lubrication bearing will overheat, leading to lubricant degradation and rapid wear.

5. Do I need to lubricate these bearings during installation?

While not strictly necessary, applying a thin layer of initial grease to maintenance free flange bearings for solar trackers during installation can assist in the initial transfer of the solid lubricant film to the shaft.