-

JDB Solid-lubricating Bearing JFBB Metric Self-lubricating Oilless Graphite Flanged Bearings Bushings

JDB Solid-lubricating Bearing JFBB Metric Self-lubricating Oilless Graphite Flanged Bearings Bushings -

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings -

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing -

JDB Solid-lubricating Bearing JEGB/JEGBK Oiless Ejector Guide Bushing Oilless Ejector Bearing

JDB Solid-lubricating Bearing JEGB/JEGBK Oiless Ejector Guide Bushing Oilless Ejector Bearing -

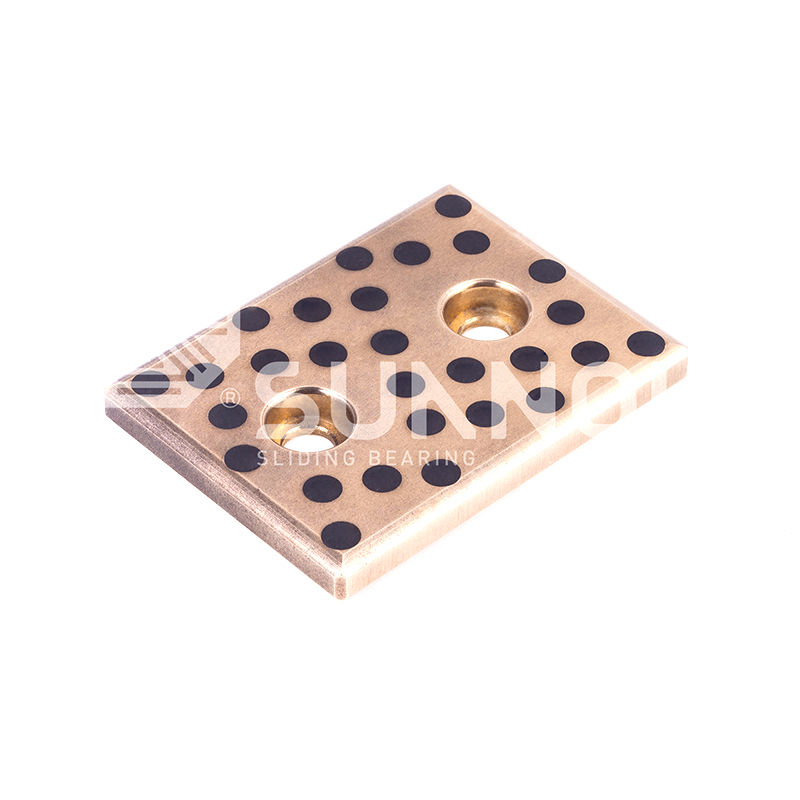

JDB Solid-lubricating Bearing JTWP No Oil Needed Wear Resistance Zero Maintenance Oilless Wear Plate

JDB Solid-lubricating Bearing JTWP No Oil Needed Wear Resistance Zero Maintenance Oilless Wear Plate -

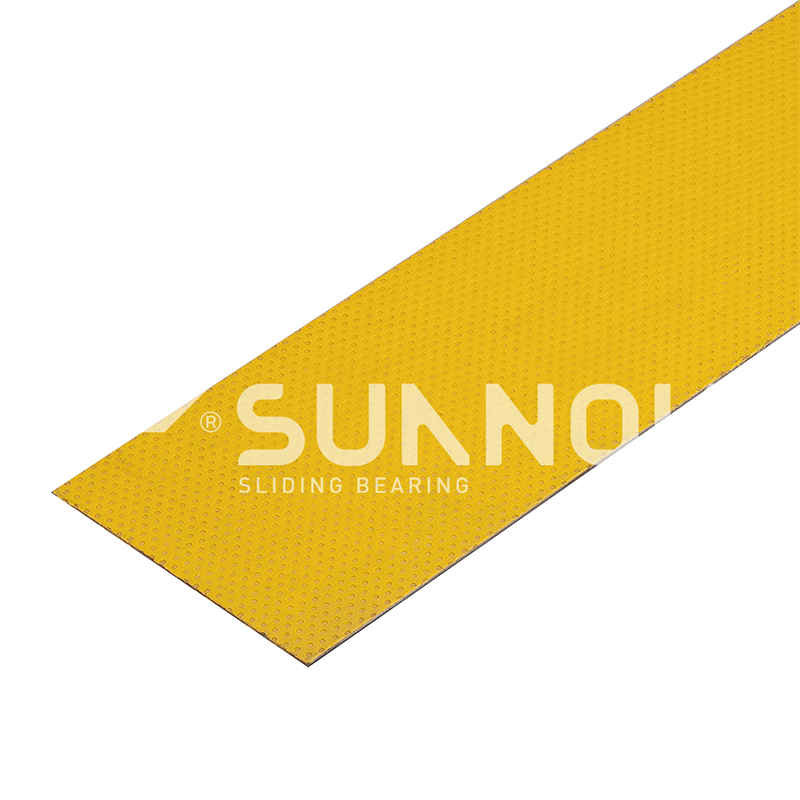

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE -

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications -

JF-800 Bi-metal Bearing JF-750 Self-Lubricating Lead Free Bi-Metal Bearing for Heavy Duty Engines Low Friction

JF-800 Bi-metal Bearing JF-750 Self-Lubricating Lead Free Bi-Metal Bearing for Heavy Duty Engines Low Friction

Can Switching to Self Lube Bearings Significantly Reduce Your Long-term Maintenance Costs and Downtime?

Industry News-- 1 1. The Economic Impact of Eliminating Manual Lubrication

- 2 2. Mitigating Downtime through Enhanced Load Capacities

- 3 3. Quality Control from the Source: Independent Casting

- 4 4. Environmental Sustainability and Compliance

- 5 Conclusion: A Star in the Self-Lubricating Industry

- 6 Frequently Asked Questions (FAQ)

In the modern industrial landscape, the relentless pursuit of operational efficiency has led engineers to re-evaluate the most fundamental components of machinery: the bearing. Traditional lubrication-dependent systems often represent a significant portion of unplanned downtime and labor costs. Transitioning to self lube bearings is no longer just a trend but a strategic technical upgrade. Zhejiang Shuangnuo Bearing Technology Co., Ltd., a manufacturer with nearly a decade of expertise, specializes in advanced copper alloy products, including brass, aluminum bronze, and tin bronze. By integrating centrifugal casting and solid lubricant embedding technology, we provide professional solutions designed to eliminate the friction points in your budget and your hardware.

1. The Economic Impact of Eliminating Manual Lubrication

The primary driver for adopting self lube bearings is the immediate reduction in man-hours dedicated to greasing schedules. While traditional bearings require consistent monitoring and manual lubricant replenishment, solid lubricant embedded bearings utilize a localized reservoir of graphite or PTFE that releases naturally during rotation. This creates a maintenance-free environment, especially in hard-to-reach locations where manual service is hazardous or physically impossible.

In comparison to traditional grease-lubricated bearings, self-lubricating variants offer a significantly lower Total Cost of Ownership (TCO) by removing the recurring costs of high-performance lubricants and the specialized labor required for their application.

| Cost Factor | Traditional Lubricated Bearings | Self Lube Bearings |

| Lubricant Procurement | High (Recurring cost) | Zero (Internalized) |

| Labor Intensity | Frequent (Weekly/Daily intervals) | Negligible (Periodic inspection only) |

| Environmental Cleanup | High (Grease leakage/disposal) | Clean (No fluid discharge) |

Source: ISO 4379:2024 Plain bearings — Copper alloy bushes — Specification and Testing

2. Mitigating Downtime through Enhanced Load Capacities

Downtime is often the result of premature bearing failure due to insufficient lubrication or abrasive wear. High load self lubricating bearings manufactured through centrifugal casting provide a denser grain structure in the base metal, which enhances structural integrity under heavy static and dynamic loads. Utilizing graphite plugged bronze bushings ensures that even under low-speed, high-pressure conditions—where oil films typically break down—the solid lubricant maintains a protective boundary layer.

While standard bushings may seize during intermittent motion or "stick-slip" scenarios, self-lubricating copper alloys provide a stable coefficient of friction that prevents catastrophic shaft damage.

| Performance Metric | Standard Metallic Bushings | Graphite Plugged Bronze Bushings |

| Friction Management | Depends on external oil film | Consistent via solid-state transfer |

| Start-up Torque | High (Dry contact) | Low (Pre-lubricated surface) |

| Seizure Resistance | Poor under lubrication failure | Excellent (Emergency run-dry capability) |

3. Quality Control from the Source: Independent Casting

Technical reliability begins with material purity. At Zhejiang Shuangnuo, we insist on independent casting production of raw materials to ensure quality from the furnace. Our process includes spectrometer testing three times—before, during, and after the melt—to confirm the precise alloy composition of our custom self lubricating copper alloy products. This rigorous control, supported by more than 80 sets of CNC machine tools and machining centers, ensures that the mechanical properties of the finished maintenance free plain bearings meet the strictest international standards.

Recent market statistics from 2024 indicate a 15% increase in the adoption of self-lubricating technology within the renewable energy and heavy construction sectors, driven by the need for components that can withstand 20+ years of service in harsh environments without human intervention.

Source: Global Bearings Market Analysis and 2025 Outlook

4. Environmental Sustainability and Compliance

Beyond costs, the transition to self lube bearings addresses increasing environmental regulations. Traditional systems often leak grease into the soil or water, leading to compliance issues. Our self lubricating bearing technical specifications highlight the "dry-running" capability, which is essential for the food processing, medical, and marine industries. By eliminating fluid lubricants, companies reduce their environmental footprint while simultaneously protecting their machinery from contamination-induced wear.

Conclusion: A Star in the Self-Lubricating Industry

Switching to self-lubricating technology is a definitive way to slash maintenance costs and maximize uptime. Zhejiang Shuangnuo Bearing Technology Co., Ltd. is committed to providing tailor-made design and customization based on the unique application characteristics of our clients. With a unique business model that integrates raw material casting with high-precision CNC finishing, we have become a new star in the industry, delivering products that guarantee performance, longevity, and professional application solutions.

Frequently Asked Questions (FAQ)

- How long do graphite plugged bronze bushings typically last?

Service life depends on load and speed, but under recommended self lubricating bearing technical specifications, they often outlast traditional bearings by 3 to 5 times due to the continuous replenishment of the solid lubricant film. - Are self lube bearings suitable for high-temperature environments?

Yes. Since our graphite plugged bronze bushings do not rely on liquid oil (which evaporates or oxidizes), they can operate effectively in temperatures exceeding 300°C depending on the specific alloy. - What is the benefit of centrifugal casting for these bearings?

Centrifugal casting eliminates impurities and gas pockets, resulting in a high load self lubricating bearings substrate that is much stronger and more wear-resistant than standard sand-cast alternatives. - Can I customize the dimensions and lubricant patterns?

Absolutely. We carry out personalized tailor-made designs, adjusting the hole pattern and lubricant composition to suit specific oscillation or rotation characteristics. - Do you provide material test reports for bulk orders?

Yes, we use in-house spectrometers and regularly commission national testing agencies to provide authoritative reports on material composition and mechanical properties for all self lube bearings.