-

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing -

JDB Solid-lubricating Bearing JEGB/JEGBK Oiless Ejector Guide Bushing Oilless Ejector Bearing

JDB Solid-lubricating Bearing JEGB/JEGBK Oiless Ejector Guide Bushing Oilless Ejector Bearing -

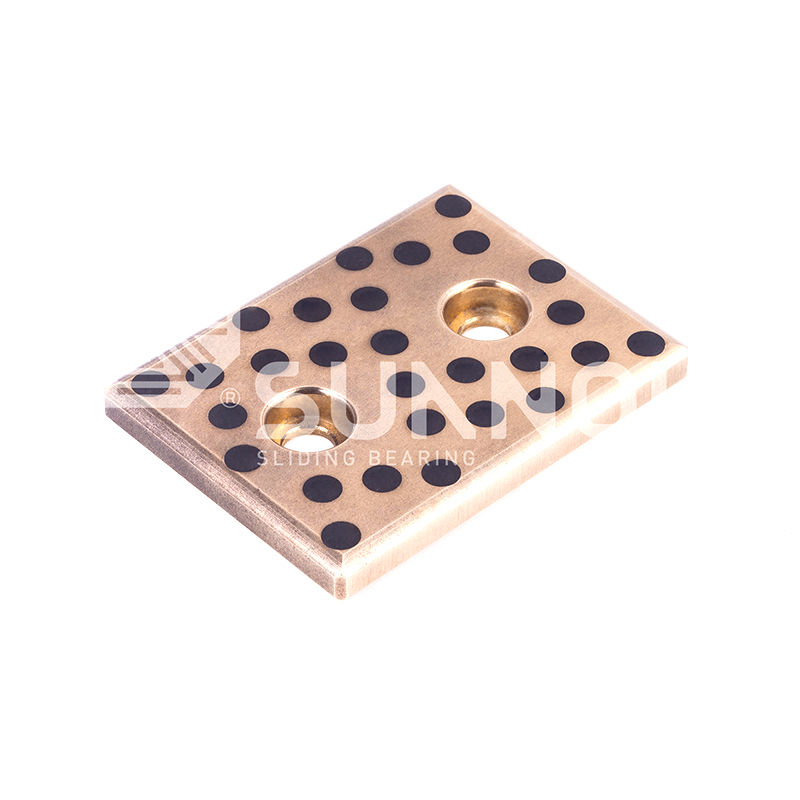

JDB Solid-lubricating Bearing JTWP No Oil Needed Wear Resistance Zero Maintenance Oilless Wear Plate

JDB Solid-lubricating Bearing JTWP No Oil Needed Wear Resistance Zero Maintenance Oilless Wear Plate -

Oil-retaining Bimetallic Bearing Self-Lubricating 200# P20 Oil-Retaining Steel Bearing Plate - Low Friction Wear-Resistant

Oil-retaining Bimetallic Bearing Self-Lubricating 200# P20 Oil-Retaining Steel Bearing Plate - Low Friction Wear-Resistant -

-

SF-2 Boundary Lubricating Bearing SF-2Y Boundary Self-lubricating Bearing - Low Friction Dry Lubricant Bushings for Industrial Machinery

SF-2 Boundary Lubricating Bearing SF-2Y Boundary Self-lubricating Bearing - Low Friction Dry Lubricant Bushings for Industrial Machinery -

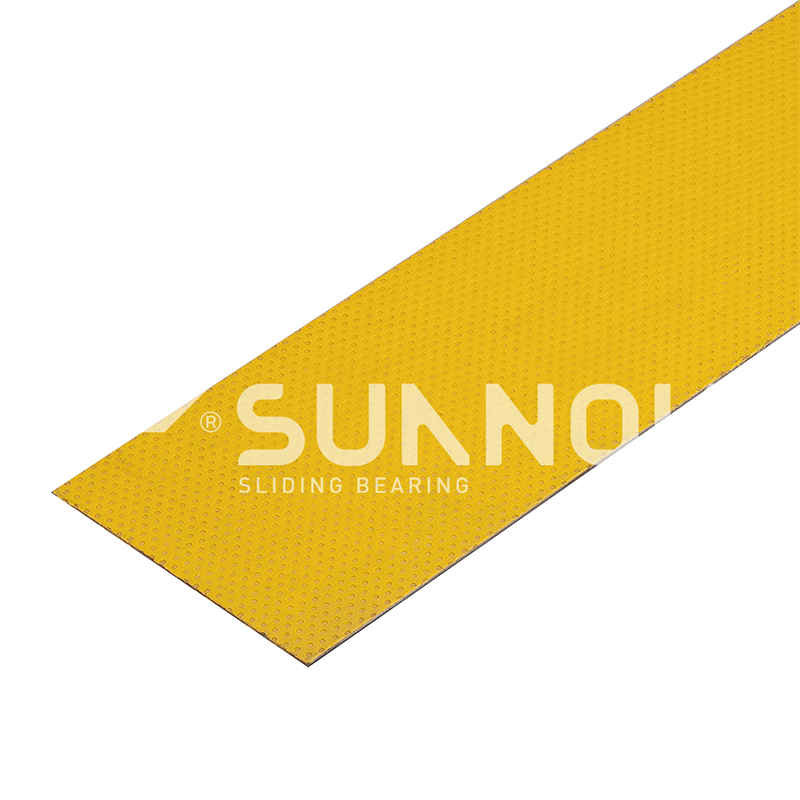

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE -

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing

What Are the Load Capacity Limits of a Bronze Graphite Bearing When Used in Underwater or Submerged Conditions?

Industry News-- 1 1. Tribological Mechanics in Submerged Environments

- 2 2. Static vs. Dynamic Load Capacity Limits

- 3 3. PV Value Constraints in Underwater Service

- 4 4. Factors Reducing Load Capacity Submerged

- 5 5. Conclusion: Engineering for Submerged Success

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. Can bronze graphite bearings rust when submerged?

- 6.2 2. Is external grease needed for self-lubricating submerged bearings?

- 6.3 3. How does saltwater affect the maximum load for bronze graphite bearings?

- 6.4 4. What is the typical underwater bearing load capacity for a dam gate?

- 6.5 5. Why choose Zhejiang Shuangnuo for underwater bearings?

- 7 Industry References

In hydraulic engineering and marine applications, the selection of bearing materials is a critical factor for system longevity. The bronze graphite bearing is a specialized mechanical component designed to operate without external oil or grease, relying on solid lubricants embedded within a high-strength copper alloy matrix. Zhejiang Shuangnuo Bearing Technology Co., Ltd., a manufacturer with a decade of expertise in centrifugal and continuous casting, specializes in these solid inlaid self-lubricating bearing products. For engineers, determining the underwater bearing load capacity requires a deep understanding of how water—as a medium—affects the friction coefficient and the film-forming ability of the graphite. This article explores the technical constraints and performance advantages of using a bronze graphite bearing in submerged environments.

1. Tribological Mechanics in Submerged Environments

In dry conditions, a bronze graphite bearing functions by transferring a thin layer of graphite to the mating shaft, creating a low-friction interface. However, in submerged conditions, water acts as both a coolant and a potential disruptive agent for the graphite transfer film. How does water affect graphite lubrication in these bearings? While water can provide auxiliary cooling, it can also lead to "hydrodynamic lift" or, conversely, prevent the solid lubricant from adhering to the shaft. Zhejiang Shuangnuo Bearing Technology utilizes spectrometer testing and national agency mechanical property validation to ensure that our tin bronze and aluminum bronze alloys maintain their structural integrity even when exposed to high-pressure aqueous environments.

Comparison: Dry vs. Submerged Friction Performance

While dry conditions rely entirely on the graphite film, submerged conditions benefit from lower operating temperatures but may face challenges with film stability at high flow rates.

| Environment | Friction Coefficient (μ) | Heat Dissipation | Wear Mechanism |

| Dry Conditions | 0.05 - 0.15 | Standard (Conductive) | Adhesive Wear |

| Submerged (Water) | 0.02 - 0.10 | Superior (Convective) | Hydrodynamic/Erosive |

2. Static vs. Dynamic Load Capacity Limits

The maximum load for bronze graphite bearings is divided into static and dynamic categories. In underwater applications, such as dam gates or ship rudders, the bronze graphite bearing often faces static loads that exceed dynamic limits due to the lack of heat buildup. Our integrated production process at Zhejiang Shuangnuo ensures that the base copper alloy, such as ZCuZn25Al6Fe3Mn3, provides a high compressive strength. However, when the bearing is submerged, the underwater bearing load capacity can be affected by the corrosion of the mating shaft, which increases surface roughness and reduces the effective contact area.

Comparison: Material Grade Load Thresholds

Different copper alloys provide varying levels of support for the graphite plugs, impacting the ultimate pressure the bearing can withstand without deformation.

| Alloy Base | Static Load Limit (Mpa) | Dynamic Load Limit (Mpa) | Submerged Suitability |

| Brass (Standard) | 60 - 80 | 20 - 30 | Moderate (Low Corrosion) |

| Aluminum Bronze | 100 - 150 | 50 - 70 | Excellent (High Strength) |

| Tin Bronze | 70 - 90 | 35 - 45 | Excellent (Corrosion Proof) |

3. PV Value Constraints in Underwater Service

For any bronze graphite bearing, the PV value (Pressure × Velocity) is the governing engineering limit. In submerged conditions, the cooling effect of water allows for a slightly higher PV limit than in dry air, but there is a caveat: graphite bearing performance in salt water. Saltwater can act as an electrolyte, promoting galvanic corrosion between the graphite (cathode) and the bronze (anode) if the alloy is not correctly selected. To mitigate this, Zhejiang Shuangnuo offers personalized tailor-made designs, selecting specific grades of aluminum bronze that resist de-aluminization and maintain load-bearing performance under the "boundary lubrication" provided by the water-graphite mixture.

4. Factors Reducing Load Capacity Submerged

Several variables can lead to a reduction in the bronze graphite bearing's effective load capacity. These include:

- Silt and Particulate Ingress: Sand or debris in the water can act as an abrasive, wearing down the self-lubricating copper alloy matrix faster than the graphite can lubricate.

- Fluid Pressure: Extreme depths can force water into the micropores of the graphite, potentially causing "plug pop-out" if the inlaid process is not precise.

- Mating Material Corrosion: A corroded shaft increases the coefficient of friction, effectively lowering the usable dynamic load for graphite bearings.

- Lubricant Leaching: While graphite is insoluble, certain chemical environments may degrade the resin binders used in lower-quality graphite plugs.

5. Conclusion: Engineering for Submerged Success

When used in underwater conditions, the bronze graphite bearing offers a robust, maintenance-free solution capable of handling significant loads. By leveraging the convective cooling of water, these bearings can often exceed their dry dynamic limits, provided the alloy base is resistant to the specific chemical composition of the fluid. At Zhejiang Shuangnuo Bearing Technology Co., Ltd., we remain committed to professional product application solutions, utilizing over 80 sets of CNC equipment and rigorous spectrometer testing to provide the high-end bearings required for the world's most demanding submerged environments.

Frequently Asked Questions (FAQ)

1. Can bronze graphite bearings rust when submerged?

Bronze is a non-ferrous alloy and does not rust in the traditional sense like steel. However, it can undergo oxidation or galvanic corrosion. Selecting high-grade tin bronze or aluminum bronze significantly minimizes these risks.

2. Is external grease needed for self-lubricating submerged bearings?

No, the bronze graphite bearing is designed to be completely self-lubricating. In fact, adding grease can sometimes attract silt and debris in underwater conditions, which may accelerate wear.

3. How does saltwater affect the maximum load for bronze graphite bearings?

Saltwater does not significantly change the mechanical load capacity directly, but it can cause corrosion over time. Corrosion reduces the smooth contact surface, which indirectly lowers the safe operating load of the self-lubricating copper alloy.

4. What is the typical underwater bearing load capacity for a dam gate?

For aluminum bronze bases, the static load capacity can reach up to 150 MPa. However, for continuous movement, engineers typically design for dynamic loads between 40-60 MPa to ensure a long safety margin.

5. Why choose Zhejiang Shuangnuo for underwater bearings?

We provide personalized tailor-made design and customization, ensuring the alloy composition and graphite plug distribution are optimized for specific submerged pressures and water chemistry.

Industry References

- ISO 4379: Plain bearings — Copper alloy bushes — Specification and Testing.

- ASTM B505/B505M: Standard Specification for Copper Alloy Continuous Castings.

- Tribology International: "The Role of Water in Solid Lubricant Performance of Metal-Matrix Composites" (2025).

- Zhejiang Shuangnuo Bearing Technology Internal Spectrometer Analysis and Load Test Reports (2026).