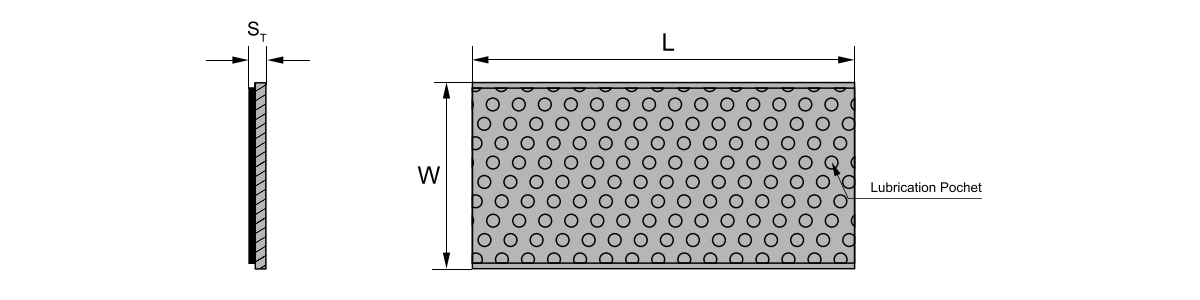

The SF-2SP Standard Metric Size Self-Lubricating Wear Strip with PTFE is an advanced maintenance-free bearing material designed for applications requiring exceptional wear resistance and consistent performance under heavy loads. These PTFE composite strips combine the benefits of polytetrafluoroethylene with reinforced fibers for superior durability.

- Self-lubricating properties eliminate the need for external lubrication

- Excellent wear resistance in both dry and wet conditions

- Low coefficient of friction (0.05-0.15) for smooth operation

- High load capacity up to 140 N/mm²

- Corrosion-resistant and maintenance-free solution

- Operates in temperatures from -200°C to +280°C

Our metric PTFE wear strips are widely used in:

- Heavy machinery guide rails and sliding surfaces

- Food processing equipment where lubrication is prohibited

- Hydraulic cylinder wear bands and guide strips

- Marine applications requiring corrosion resistance

- Automotive components for reduced friction and noise

- Construction equipment pivot points and joint surfaces

Unlike conventional bearing materials, our SF-2SP series offers:

- Longer service life - Up to 5x longer than traditional materials

- Precision metric sizing - Perfect fit for European machinery standards

- Custom fabrication - Available in non-standard sizes upon request

- Cost-effective solution - Reduces maintenance downtime and lubrication costs

- Quality assurance - Manufactured to ISO 9001 standards

Installation Guidelines

For optimal performance of your self-lubricating strips:

- Ensure mating surfaces are clean and free from debris

- Use appropriate adhesive for permanent bonding

- Allow proper curing time before applying load

- For large surfaces, consider expansion joints every 500mm

- Avoid sharp impacts during installation

Frequently Asked Questions

Q: Can these PTFE strips be used in underwater applications?

A: Yes, the SF-2SP material performs well in both fresh and saltwater environments.

Q: What is the difference between standard and metric sizes?

A: Our metric series follows international (SI) measurements for compatibility with European and Asian machinery.

Q: How do these compare to nylon wear strips?

A: SF-2SP offers lower friction, higher temperature resistance, and better chemical resistance than nylon alternatives.