-

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing -

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing -

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing -

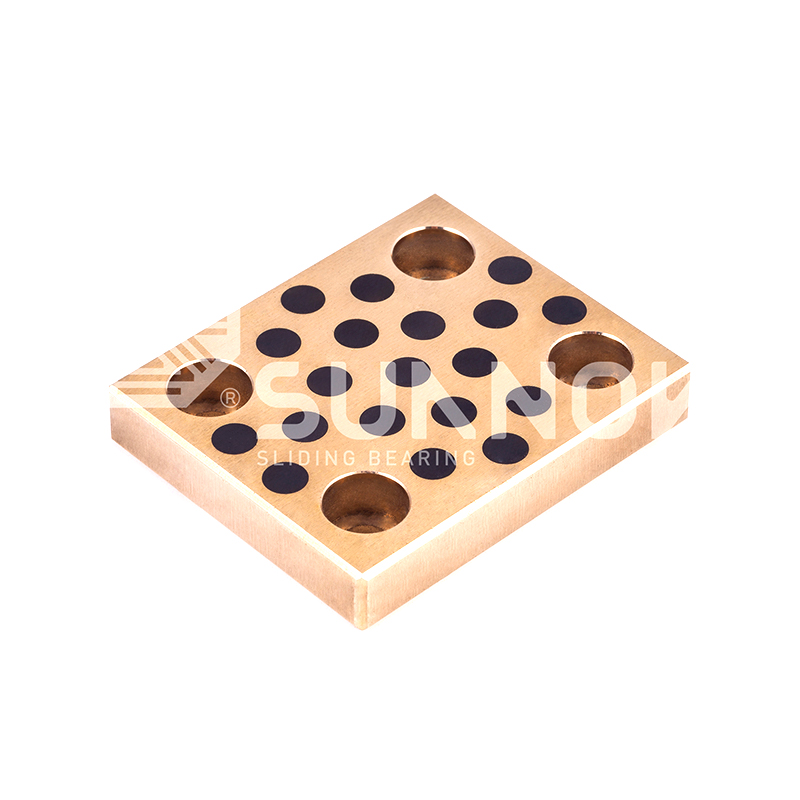

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate -

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing -

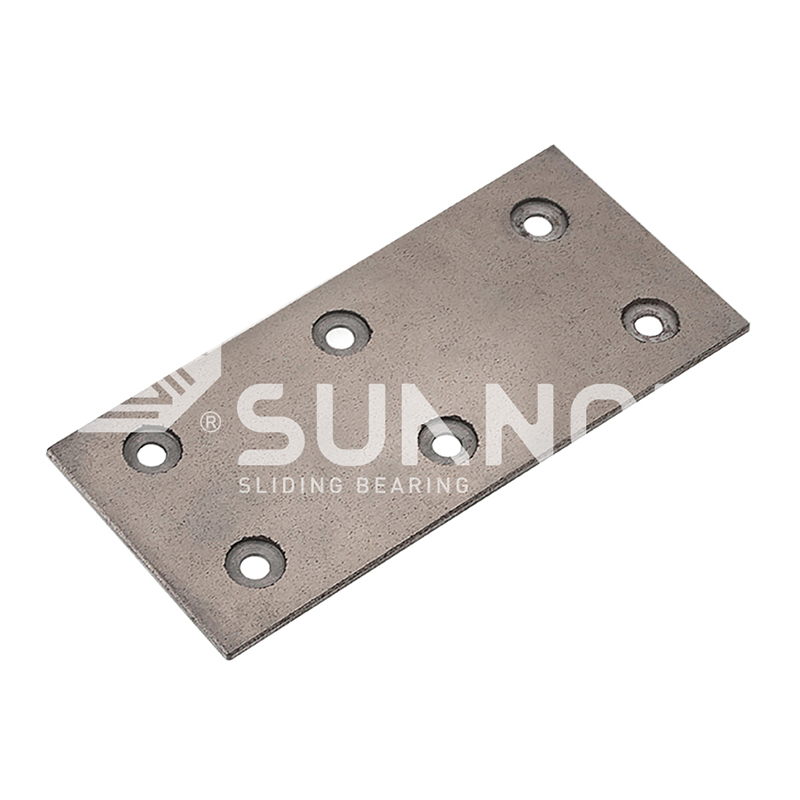

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface -

-

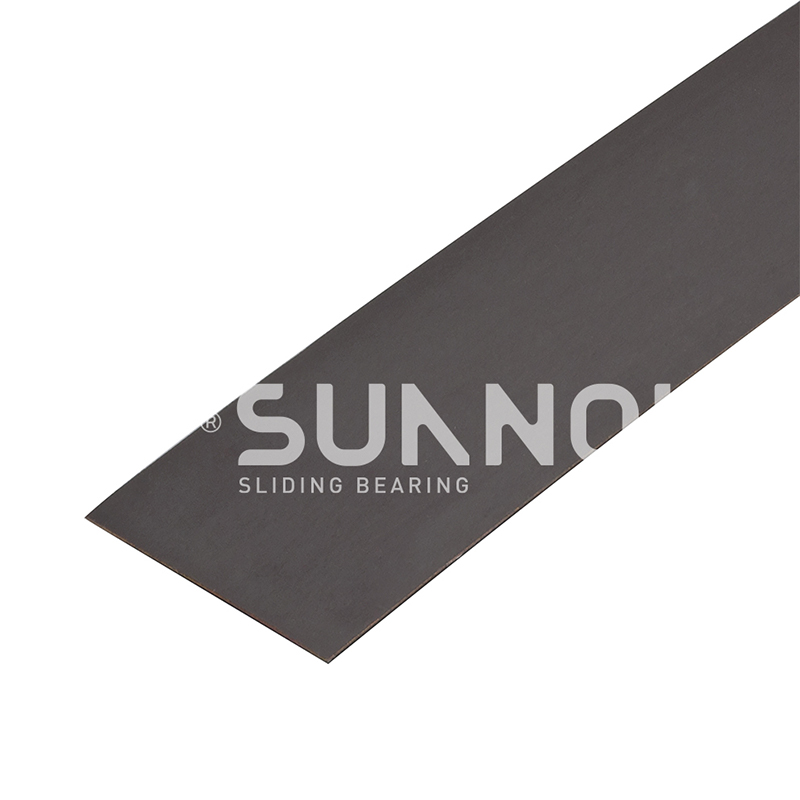

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip

Does Your Self Lubrication Bearing Meet the PV Limits Required for High-Speed Industrial Machinery?

Industry News-- 1 Understanding the PV Value in Bearing Engineering

- 2 High-Speed Challenges: Thermal Dissipation and Centrifugal Integrity

- 3 Specifying the Right Lubricant for Industrial PV Limits

- 4 Maintenance and Failure Prediction

- 5 Conclusion: Engineering for the Future of Automation

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. How do I perform a PV value calculation for bearings?

- 6.2 2. Is self lubrication bearing maintenance free in high-speed use?

- 6.3 3. How to choose self lubricating bearings for high speed vs. high load?

- 6.4 4. What are the common signs of self lubricating bearing failure?

- 6.5 5. Can I get a custom self lubricating bearing design for my specific machine?

- 7 Industry References

In the realm of mechanical engineering, the transition toward maintenance-free operation has positioned the self lubrication bearing as a critical component in modern assembly. However, for high-speed industrial machinery, simply selecting a "greaseless" option is insufficient. Engineers must verify if the component can withstand the specific PV (Pressure-Velocity) demands of the application. Zhejiang Shuangnuo Bearing Technology Co., Ltd. has spent nearly a decade perfecting the research and production of copper alloy lubricants. By utilizing advanced centrifugal casting and spectrometer-verified material composition, we ensure that every self lubrication bearing provides the thermal stability and load capacity required for the most demanding industrial environments.

Understanding the PV Value in Bearing Engineering

The PV value represents the product of the specific load (P) and the sliding velocity (V). It is the primary metric used to determine the heat generation rate at the bearing interface. If the operational PV exceeds the material's limit, the lubricating film—whether it be graphite, MoS2, or a PTFE-based composite—will fail, leading to rapid adhesive wear. When assessing self lubricating bearing material properties, engineers must distinguish between the static load capacity and the dynamic PV limit. At Zhejiang Shuangnuo, we utilize integrated production from raw material casting to finished CNC machining to ensure our brass and aluminum bronze bases maintain structural integrity under high-energy friction.

Comparison: Standard Bronze vs. Solid Inlaid Self-Lubricating Bearings

Traditional bronze bearings require constant oil film maintenance to prevent seizure, whereas solid inlaid bearings utilize a sacrificial lubricant layer to operate safely at higher PV thresholds.

| Performance Factor | Traditional Grease-Lubricated Bronze | Solid Inlaid Self Lubrication Bearing |

| Lubrication Method | External (Manual/Auto pump) | Internal (Solid lubricant plugs) |

| Maintenance Requirement | High (Frequent downtime) | Virtually Zero |

| Max PV Limit (Approx.) | Dependent on oil film thickness | Up to 1.65 N/mm² · m/s (Standard) |

| Coefficient of Friction | 0.08 - 0.15 (with grease) | 0.03 - 0.20 (Dry operation) |

High-Speed Challenges: Thermal Dissipation and Centrifugal Integrity

High-speed operation introduces two main risks: accelerated heat buildup and centrifugal force displacement. A self lubrication bearing must be able to dissipate frictional heat through its housing to avoid thermal expansion that could seize the shaft. Zhejiang Shuangnuo Bearing Technology Co., Ltd. specializes in centrifugal casting, a process that creates a denser grain structure in copper alloys compared to traditional sand casting. This improved density results in higher thermal conductivity and superior mechanical strength, which are essential when evaluating how to choose self lubricating bearings for high speed applications. Furthermore, our spectrometer testing confirms material purity, ensuring no inclusions compromise the dynamic balance of the machinery.

Comparison: Casting Methods and Material Density

Centrifugal casting provides a significantly more uniform and dense material structure than metal mold or sand casting, directly impacting the bearing's lifespan in high-RPM environments.

| Casting Process | Structural Uniformity | Porosity Level |

| Sand Casting | Low (Variable grain size) | High (Potential for weak spots) |

| Continuous Casting | Moderate | Low |

| Centrifugal Casting (Shuangnuo) | High (Dense, refined grain) | Negligible |

Specifying the Right Lubricant for Industrial PV Limits

The choice of solid lubricant is as vital as the metal base. For high-speed machinery, the lubricant must have a low coefficient of friction to minimize heat generation. Researching self lubricating bearing lubricant types reveals that graphite-based inlays are excellent for high temperatures, while PTFE-based sintered bimetallic products are superior for high-velocity, low-load scenarios. Our 80+ sets of CNC machine tools allow us to precisely machine the "inlaid" holes, ensuring the lubricant plugs remain secure even under intense vibration and centrifugal forces.

Advanced Design Factors:

- Solid Inlaid Technology: Lubricant covers 20-30% of the surface area for optimal film formation.

- Sintering Technology: Bimetallic layers provide a combination of steel-backed strength and bronze-faced low friction.

- Customized Solutions: Tailor-made designs based on spectrometer-verified alloys for specific self lubricating bearing load capacity requirements.

Maintenance and Failure Prediction

While these components are "self-lubricating," they are not immortal. Engineers must monitor the signs of self lubricating bearing failure, such as unusual acoustic signatures or a rise in localized temperature. Because our company implements integrated production from raw material to finished product, we can provide authoritative test reports on mechanical properties, helping engineers calculate precise replacement cycles and avoid catastrophic failures in high-speed lines.

Conclusion: Engineering for the Future of Automation

The reliability of a self lubrication bearing in high-speed industrial machinery is a factor of both metallurgical excellence and precise PV limit calculation. Zhejiang Shuangnuo Bearing Technology Co., Ltd. remains committed to "integrity-based" manufacturing, ensuring every component—from brass to tin bronze—meets the high-end market's standards. By controlling the casting process from the furnace to the spectrometer, we provide the professional application solutions that allow modern machinery to run faster, longer, and cleaner.

Frequently Asked Questions (FAQ)

1. How do I perform a PV value calculation for bearings?

The PV value is calculated by multiplying the Pressure (P = Load / Projected Area) by the Velocity (V = π * Diameter * RPM). Compare this result to the manufacturer's maximum PV limit to ensure a safety margin of at least 20%.

2. Is self lubrication bearing maintenance free in high-speed use?

While they do not require external oil or grease, they are not maintenance-free in terms of inspection. High-speed applications should be checked periodically for debris and thermal discoloration to ensure the PV limits are not being exceeded.

3. How to choose self lubricating bearings for high speed vs. high load?

For high speed, prioritize materials with high thermal conductivity (like Aluminum Bronze) and lubricants with the lowest friction coefficients. For high load, prioritize the compressive strength of the base alloy (like Tin Bronze) and larger lubricant surface areas.

4. What are the common signs of self lubricating bearing failure?

Key indicators include increased vibration, a high-pitched squealing sound (indicating the solid lubricant is depleted), and visible copper powder/debris near the bearing housing.

5. Can I get a custom self lubricating bearing design for my specific machine?

Yes. Zhejiang Shuangnuo offers personalized tailor-made design and customization, selecting the specific copper alloy and lubricant inlay pattern that best suits your product's speed and load characteristics.

Industry References

- ISO 4379: Plain bearings — Copper alloy bushes — Specification and testing.

- ASTM B271: Standard Specification for Copper-Base Alloy Centrifugal Castings.

- DIN 1494: Plain bearings — Sintered bushes — Dimensions and tolerances.

- "Tribology of Solid Lubricants in Industrial Machinery," Journal of Engineering Materials.