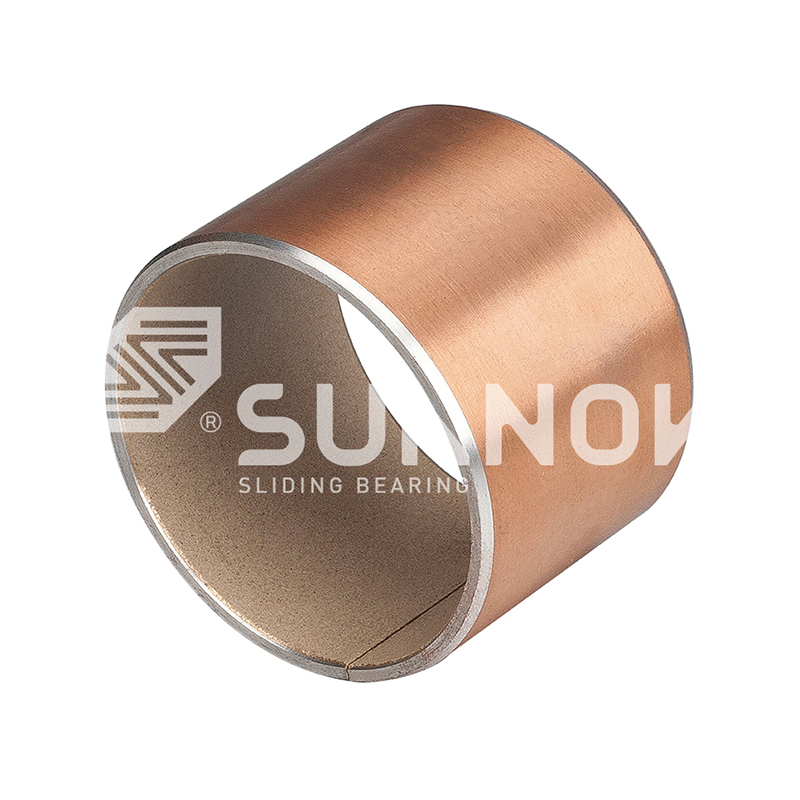

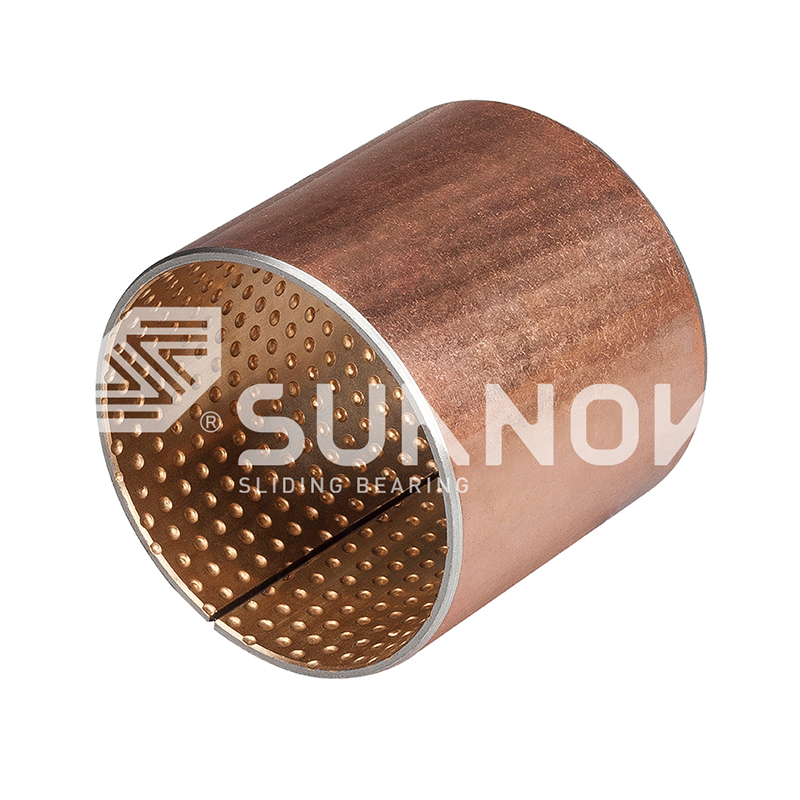

The SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing is a high-performance, maintenance-free bearing made from special composite materials. It features excellent wear resistance and self-lubricating properties. As a Lead-Free Boundary Bush, it meets environmental standards and is ideal for high-load, low-speed oscillating or rotating applications. It is widely used in automotive, construction machinery, agricultural equipment, and industrial automation.

- Self-Lubricating & Maintenance-Free – Embedded solid lubricants eliminate the need for external oiling, reducing maintenance costs in hard-to-reach environments.

- High Wear Resistance & Long Service Life – Made from high-strength composite materials with a low friction coefficient, ensuring durability and extended equipment lifespan.

- Eco-Friendly & Lead-Free Design – Complies with RoHS standards, making it safe for food, medical, and other sensitive industries.

- High Load Capacity – Optimized structural design supports heavy radial loads and impact forces, suitable for heavy-duty machinery.

- Low Noise & Smooth Operation – The self-lubricating layer minimizes metal-to-metal friction, reducing noise and improving operational stability.

Applications

Automotive Industry

Suspension systems, steering mechanisms, clutch bearings

Construction Machinery

Excavators, forklift joint bearings

Agricultural Equipment

Tractors, harvester transmission components

Industrial Automation

Conveyor belts, packaging machinery sliding parts

✅ Strict Quality Control – Every batch undergoes wear resistance and compression testing to ensure consistent performance.

✅ Customization Services – Supports non-standard sizes to meet various operational needs.

✅ Global Certifications – Complies with ISO, ASTM, and other international standards for hassle-free export.

✅ Fast Delivery – Ample inventory supports small trial orders, minimizing lead times.

Frequently Asked Questions (FAQ)

Q: What are the advantages of SF-2 self-lubricating bearings compared to metal bearings?

A: No lubrication required, corrosion-resistant, low noise, and lighter weight—ideal for maintenance-free applications.

Q: Do you offer OEM/ODM services?

A: Yes, we provide material and size customization.