Product Features

- High Wear Resistance: The bimetallic structure of a steel backing and bronze overlay offers superior load-bearing capacity and longevity, crucial for heavy-duty industrial applications.

- Oil-Free Self-Lubricating: Integrated solid lubricants within the bronze layer ensure continuous lubrication without external oil or grease, making it an ideal maintenance-free sliding bearing solution for hard-to-reach bearing locations.

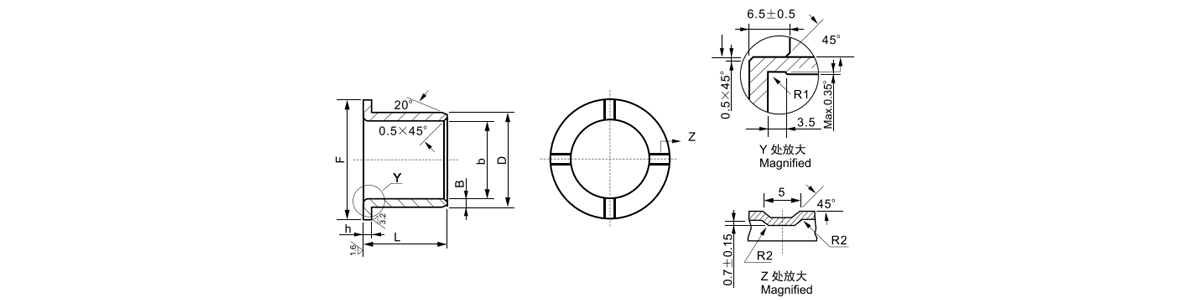

- Standard Metric Flange Design: The standardized flange provides a reliable means of axial location, simplifying bushing installation and preventing movement along the shaft, which is a key consideration for industrial flange bearing replacement.

- Corrosion Resistance: The bronze material offers inherent resistance to corrosion, enabling reliable performance in environments exposed to moisture or certain chemicals.

Product Description

The JF-800F bimetallic flanged bearing is engineered to provide robust performance in demanding industrial environments where heavy loads and slow, intermittent movements are common. Its core design combines a low-carbon steel backing for mechanical strength and a sintered bronze layer infused with solid lubricants for excellent wear properties. This design addresses common pain points such as bushing wear and failure, and the need for frequent lubrication, providing a reliable and durable alternative to traditional lubricated bushings. This product adheres to established manufacturing standards to ensure dimensional consistency and performance reliability for OEM machine builders and MRO professionals.

This self-lubricating flanged bushing is a direct solution for upgrading components and minimizing downtime, aligning with key objectives for industrial plant maintenance and improving equipment reliability. It is a cost-effective choice for engineers seeking a high-performance flanged bearing without the complexities of an external lubrication system.

Application Areas

This product is suitable for the following industrial applications:

- Heavy machinery, including construction and agricultural equipment.

- Lifting and hoisting devices, such as cranes and forklifts.

- General industrial machinery where bimetal flange bushing replacement is required.

- Systems where external lubrication is impractical or undesirable, such as underwater equipment or food processing machinery.

Common Procurement Inquiries

1. How do these self-lubricating bimetallic flange bearings compare to bronze bushings requiring regular grease?

The JF-800F bearing offers a significant advantage by eliminating the need for periodic lubrication, reducing maintenance time and costs. While a traditional bronze bushing requires continuous grease or oil to prevent friction and wear, our bimetallic bearing's integrated solid lubricants provide consistent, reliable performance throughout its service life. This makes it a superior option for applications with high labor costs for maintenance or in environments where lubrication is difficult. The choice depends on your specific operational demands. Our technical team can provide a direct comparison for your specific application to help you make an informed decision.

2. What is the typical service life of these bearings, and how do they withstand extreme loads without lubrication?

The service life is highly dependent on the application's specific operating conditions, including load, speed, and temperature. However, the JF-800F is engineered with a high-strength steel backing and a specially formulated bronze layer to withstand extreme static and dynamic loads. The embedded solid lubricants are released gradually as the shaft rotates, forming a protective film that significantly reduces friction and wear even under demanding conditions. To provide an accurate estimate for your project, our engineers require details on your specific load, speed, and duty cycle. We offer a free engineering consultation to determine the ideal bearing type and predicted service life for your heavy-duty bushing application.