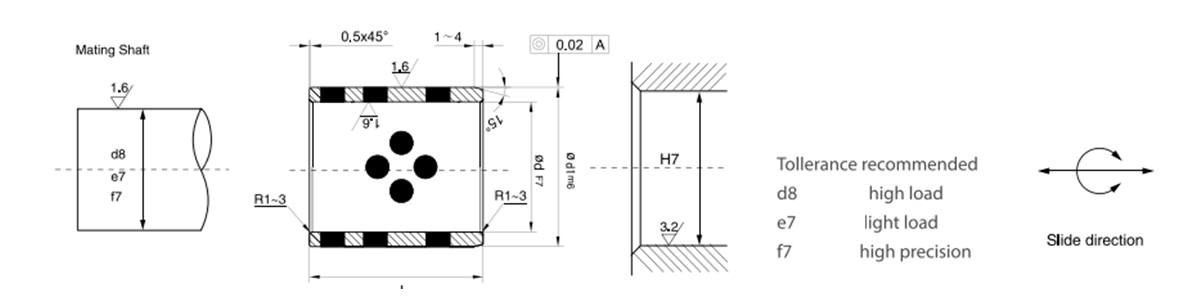

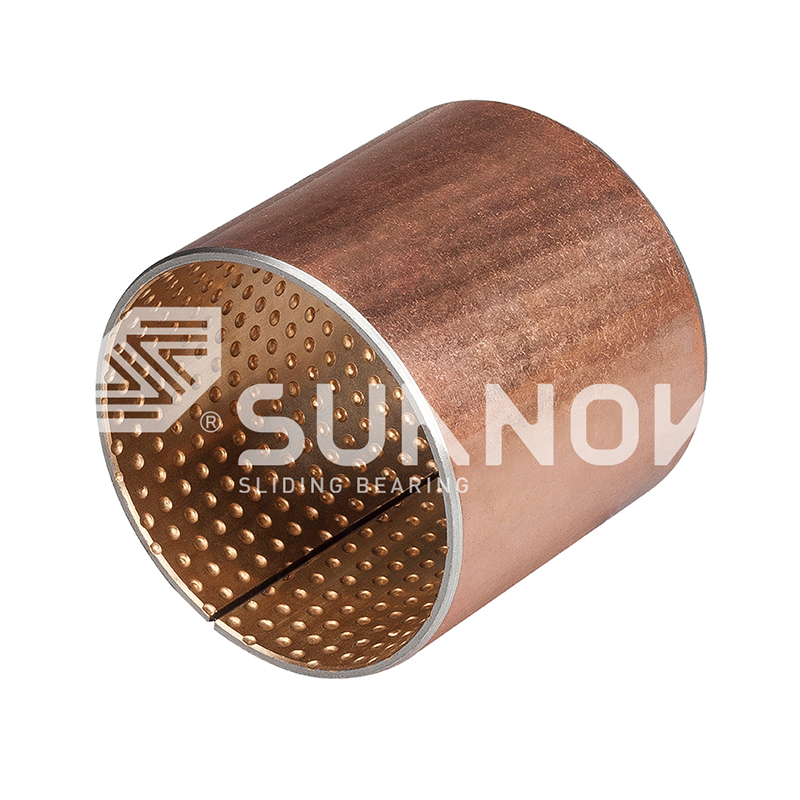

JDB-5 is a high-performance solid lubricant bearing that uses a steel backing matrix embedded with wear-resistant materials and solid lubricants. It can operate in harsh working conditions such as oil-free or high temperature and high load. Its self-lubricating properties reduce the friction coefficient and extend the service life. It is suitable for low-speed heavy load, reciprocating swing, dust pollution or environments that cannot be frequently maintained.

FAQ

Q1: What are the main application areas of JDB-5 bearings?

A1: JDB-5 bearings are widely used in metallurgical equipment (continuous casting machines, rolling mills), mining machinery (crushers, conveyors), engineering machinery (excavator booms), water conservancy gates and automated production lines. Its high temperature resistance, dust resistance and maintenance-free characteristics make it particularly suitable for harsh working conditions, such as transmission parts in high-temperature furnaces or dusty environments.

Q2: What are the advantages of JDB-5 compared with traditional rolling bearings?

A2: JDB-5 does not require external lubrication to avoid failure due to grease drying; the wear-resistant layer and solid lubricant can reduce wear and extend life. It is suitable for low-speed heavy load, swing or impact load scenarios, while rolling bearings are prone to fatigue spalling under such conditions. In addition, JDB-5 has a compact structure and can be customized to meet the needs of special equipment.

Q3: What are the limit working parameters of JDB-5 bearings?

A3: JDB-5 bearings can withstand static loads of up to 140MPa, with an operating temperature range of -40℃~+300℃ and instantaneous high temperature resistance of up to 500℃. The recommended linear speed is ≤2m/s, and the PV value under dry friction conditions is ≤3.0MPa·m/s. If higher performance is required, the corrosion resistance or load capacity can be improved by adjusting the material ratio (such as adding a copper-based composite layer).