The SF-1SP Standard Metric Size Self-Lubricating Composite Slide Strip is a high-performance, low-friction engineered composite strip designed for mechanical sliding systems. Made from reinforced fibers and solid lubricants, it offers excellent wear resistance and self-lubricating properties, making it ideal for sliding, guiding, and support components in various industrial equipment.

✅ Low Friction Coefficient – Reduces motion resistance, improves operational efficiency, and extends service life.

✅ Maintenance-Free Self-Lubrication – Eliminates the need for additional lubrication, lowering maintenance costs in harsh environments.

✅ Standard Metric Sizes – Available in multiple standard dimensions (e.g., 10mm×10mm, 20mm×20mm) for easy replacement and integration.

✅ High Load Capacity – Composite structure ensures stable performance even under heavy loads.

✅ Corrosion & Wear Resistant – Suitable for humid, dusty, or chemical environments, reducing metal component wear.

Typical Applications

- Automated machinery guide rails

- Sliding components in packaging equipment

- CNC machine tool guide strips

- Food processing machinery (oil-free lubrication compliant)

- Support shims for construction machinery

Why Choose Our SF-1SP Slide Strip?

Our SF-1SP self-lubricating slide strip is made from premium composite materials, ensuring long-term reliability and outperforming traditional metal or plastic strips. The standardized sizing allows seamless compatibility with existing equipment, minimizing downtime. Whether for low-friction rail systems or high-load sliding applications, the SF-1SP delivers exceptional performance.

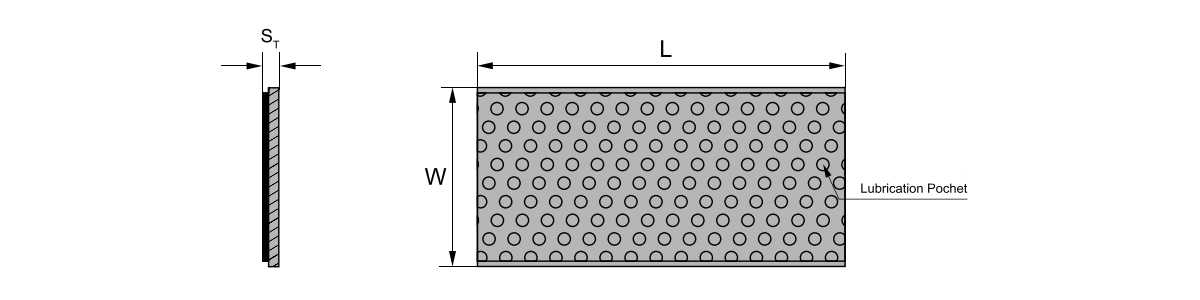

| Material |

Fiber-reinforced composite + solid lubricant |

| Friction Coefficient |

0.05~0.15 (dynamic) |

| Operating Temperature |

-40°C to +200°C |

| Standard Sizes |

10×10mm, 15×15mm, 20×20mm (customizable) |

| Load Capacity |

≥50MPa |

Frequently Asked Questions (FAQ)

Q: Does the SF-1SP strip require additional lubrication?

A: No, it features a self-lubricating design for long-term maintenance-free operation.

Q: Can custom non-standard sizes be provided?

A: Yes, we offer custom thickness and width options—contact our sales team for details.

Q: Which industries is it suitable for?

A: Widely used in automation, packaging, machine tools, food processing, and heavy machinery industries.