Product Features

- Dual-Layer Composite Structure: Features a high-quality bronze alloy backing for exceptional load-bearing capacity and a pure copper inner lining for superior thermal conductivity. This design is optimized for environments requiring effective heat dissipation.

- Low Friction & Wear Resistance: The copper running surface provides a low coefficient of friction, significantly reducing wear and tear on mating components. This extends the service life of both the bushing and the shaft.

- Enhanced Corrosion Resistance: The unique composite material offers robust protection against oxidation and chemical corrosion, making it suitable for operation in challenging industrial settings and humid environments.

- Self-Lubricating Grooves: Precision-machined oil grooves or grease pockets on the inner diameter ensure continuous lubrication, reducing maintenance intervals and preventing premature failure. Ideal for applications where frequent re-lubrication is impractical.

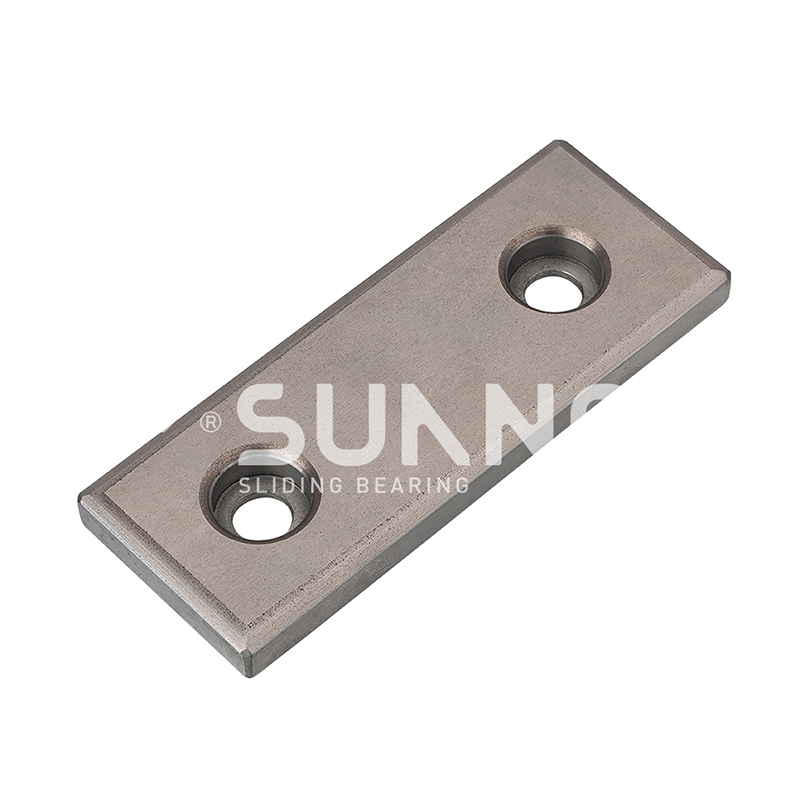

Product Description

The FB091 copper wrapped bronze bushing is an advanced composite bearing engineered for demanding industrial applications. It is designed to provide reliable performance in oscillating, rotating, and sliding motions under moderate to high loads. The core technology leverages a sintered bronze powder backing onto a steel strip, followed by the seamless application of a pure copper layer. This construction delivers a product with the high load capacity of bronze and the excellent thermal properties of copper, addressing critical challenges in industrial bearing lubrication and high-temperature bearing applications. It is an effective solution for engineers seeking to replace traditional cast bronze bearings or steel bushings to improve efficiency and longevity.

Manufactured to strict ISO 3547 standards, our FB091 series bushings undergo rigorous quality control, including dimensional accuracy checks, material composition analysis, and endurance testing. This ensures consistent performance and reliability, providing a dependable solution for heavy-duty bearing specifications. The wrapped design allows for a cost-effective alternative to solid bronze bushings without compromising on structural integrity or operational performance. Our products are widely used in a variety of machinery, from agricultural equipment to construction vehicles, where a high-performance, maintenance-friendly bearing is required.

Application Fields

The FB091 copper wrapped bronze bushing is specifically engineered for demanding environments where superior thermal management and wear resistance are critical. Key applications include:

- Hydraulic and Pneumatic Cylinders: For smooth rod guiding and robust support in high-pressure systems.

- Agricultural Machinery: Used in implements and tractors to withstand dirt, dust, and heavy loads.

- Construction and Mining Equipment: Found in excavators, bulldozers, and cranes where durability and resistance to harsh conditions are essential.

- General Industrial Machinery: Provides reliable bearing solutions for gearboxes, pumps, and conveyor systems.

Common Procurement Questions

1. How does the FB091 bushing compare to a standard bronze bushing for a high-load, low-speed application?

The FB091, with its wrapped copper-bronze structure, offers superior thermal dissipation compared to a solid cast bronze bushing. While both provide excellent load capacity, the FB091's unique design and manufacturing process allow for a more consistent and controlled lubricating surface, which can reduce operational temperature and extend service life. For your specific heavy-duty bearing selection criteria, we recommend evaluating the operating temperature, load profile, and required maintenance intervals. Our technical team can assist you with a detailed analysis to determine the optimal solution for your machinery.

2. What are the key maintenance requirements and what is the typical service life for the FB091 in an intermittent-use application?

The FB091 is engineered to be a low-maintenance solution. While the internal oil grooves are designed to hold lubricant and extend intervals between service, periodic re-lubrication is still a best practice to ensure peak performance and longevity. The service life is highly dependent on the specific operating conditions, including load magnitude, speed, temperature, and environmental factors. For an intermittent-use application, the service life is generally longer than in a continuous-run scenario due to less constant friction and heat buildup. To get a precise estimate for your project, please provide us with your industrial bushing failure analysis data or operational parameters, and our engineers can perform a performance simulation.