JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing is a high-performance self-lubricating bronze bushing bearing. It adopts a special casting process and is embedded with solid lubricants (such as graphite or PTFE) inside. It can operate stably for a long time without oil or under low speed and heavy load conditions. This product has excellent wear resistance, impact resistance and corrosion resistance, and is suitable for high load, low speed or reciprocating motion conditions.

FAQ

Q1: What industries are JDB-600 self-lubricating bronze bushings suitable for?

A1: JDB-600 is widely used in engineering machinery, metallurgical equipment, mining machinery, ships, injection molding machines, agricultural machinery and other fields. It is especially suitable for high temperature, heavy load, low speed or frequent lubrication conditions, such as rolling mill guides, hydraulic cylinder supports, mold guides and other scenes, which can significantly reduce maintenance costs and extend service life.

Q2: What is the self-lubricating principle of this product? Is additional oiling required?

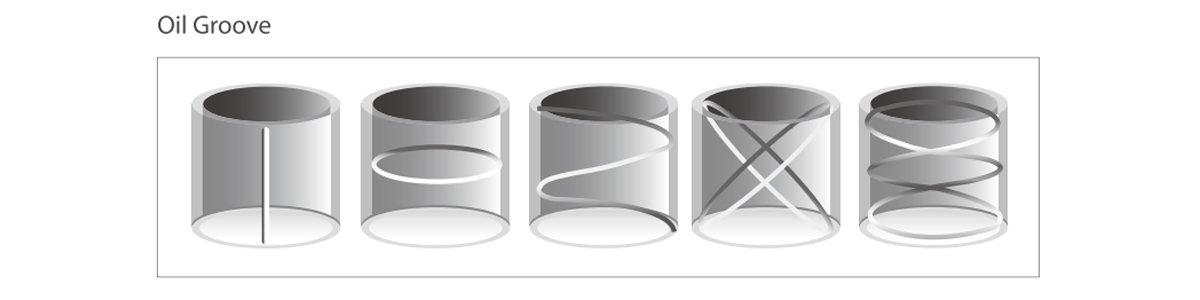

A2: JDB-600 uses embedded solid lubricants (such as graphite/molybdenum disulfide), which form a uniform lubricating film during the friction process to achieve self-lubrication. Usually no additional refueling is required, especially suitable for difficult-to-maintain or oil-free environments (such as food machinery, clean workshops). However, under extreme loads or long-term high-speed operation, a small amount of grease can be used to improve performance.

Q3: What are the advantages of JDB-600 compared to ordinary bronze bushings?

A3: JDB-600 has a longer service life and a lower coefficient of friction. Its self-lubricating properties can reduce maintenance requirements by more than 80%. In addition, it is resistant to high temperatures (up to 300°C), anti-seizure, and adaptable to dusty and humid environments. Compared with ordinary bushings that require frequent refueling, JDB-600 can still maintain stable performance under harsh working conditions and has a lower overall cost.