-

JDB Solid-lubricating Bearing JDB650 Self-Lubricating Brass Bushing Oilless Bearings

JDB Solid-lubricating Bearing JDB650 Self-Lubricating Brass Bushing Oilless Bearings -

JDB Solid-lubricating Bearing JFBB Metric Self-lubricating Oilless Graphite Flanged Bearings Bushings

JDB Solid-lubricating Bearing JFBB Metric Self-lubricating Oilless Graphite Flanged Bearings Bushings -

JDB Solid-lubricating Bearing GB61 Copper NAAMS Standard Flanged Solid-lubricating Bearing

JDB Solid-lubricating Bearing GB61 Copper NAAMS Standard Flanged Solid-lubricating Bearing -

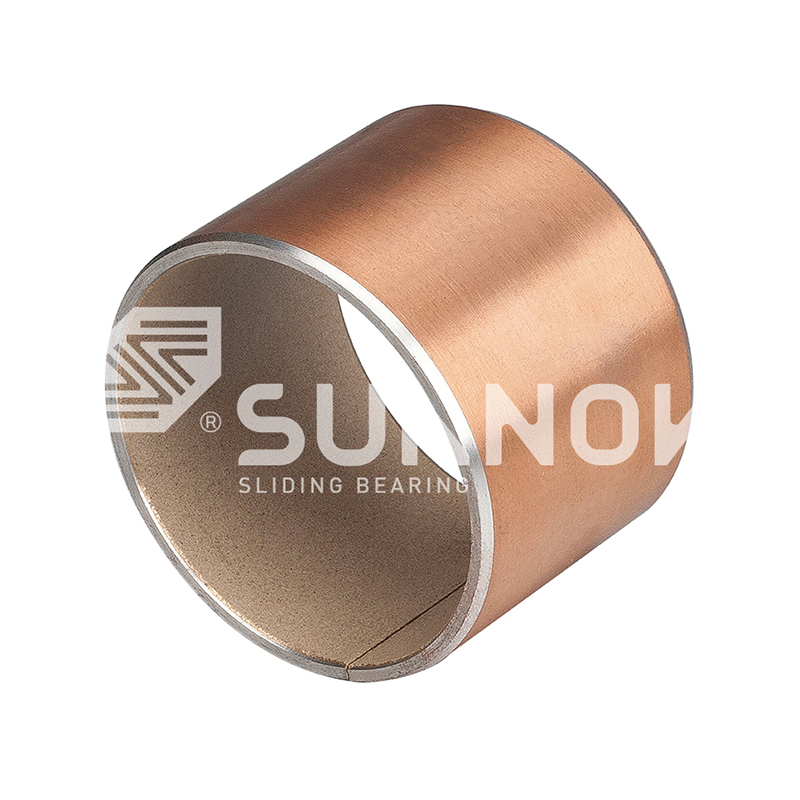

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing -

JF-800 Bi-metal Bearing JF-750 Self-Lubricating Lead Free Bi-Metal Bearing for Heavy Duty Engines Low Friction

JF-800 Bi-metal Bearing JF-750 Self-Lubricating Lead Free Bi-Metal Bearing for Heavy Duty Engines Low Friction -

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing -

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

Dimensional Tolerances and Installation Guidelines for Oilless Bronze Bushing

Industry News-- 0.1 1. Critical Dimensional Tolerances

- 0.2 2. Press-Fit Installation Considerations

- 0.3 3. Surface Roughness Requirements

- 0.4 4. Comparison with Cylindrical Bronze Bearing Standards

- 0.5 5. Best Practices for Installation

- 1 FAQs

- 1.1 1. What are the key dimensional tolerances for oilless bronze bushings?

- 1.2 2. How should press-fit oilless bronze bushings be installed?

- 1.3 3. What are the surface roughness requirements?

- 1.4 4. How do oilless bronze bushings compare with standard cylindrical bronze bearings?

- 1.5 5. Are there maintenance considerations for press-fit oilless bronze bushings?

The oilless bronze bushing is widely used in industrial applications due to its self-lubricating properties and high load capacity. For optimal performance, understanding the critical dimensional tolerances and installation requirements, including inner diameter, outer diameter, length, interference fits, and surface roughness, is essential.

1. Critical Dimensional Tolerances

Key dimensions of oilless bronze bushing include inner diameter (ID), outer diameter (OD), and length (L). Maintaining tight tolerances ensures proper load distribution and minimal vibration during operation.

| Dimension | Recommended Tolerance | Impact on Performance |

|---|---|---|

| Inner Diameter (ID) | +0/-0.01 mm | Ensures precise shaft fit and smooth rotation |

| Outer Diameter (OD) | +0/-0.02 mm | Ensures proper press-fit into housing |

| Length (L) | ±0.05 mm | Maintains load distribution along the bearing surface |

2. Press-Fit Installation Considerations

During press-fit installation of press-fit bronze bushing, interference fit, alignment, and uniform pressing are critical. Excessive interference can cause deformation, while insufficient interference may lead to slippage.

| Parameter | Recommended Value | Effect |

|---|---|---|

| Interference Fit | 0.01–0.03 mm depending on OD | Optimal for stable operation and load transfer |

| Pressing Method | Uniform hydraulic or mechanical press | Prevents bushing distortion and uneven stress |

| Alignment | Axial alignment ±0.02 mm | Ensures smooth rotation and prevents premature wear |

3. Surface Roughness Requirements

The mating surfaces of self-lubricating bronze sleeve and shaft require precise surface roughness to minimize friction and wear. Ideal values are:

- Bushing inner diameter: Ra 0.2–0.4 μm

- Shaft surface: Ra 0.2–0.8 μm

- Press-fit housing bore: Ra 1.6 μm maximum

4. Comparison with Cylindrical Bronze Bearing Standards

Compared with standard cylindrical bronze bearing tolerances, oilless bronze bushings demand tighter ID/OD control due to their self-lubricating nature and load-bearing capabilities:

| Type | ID Tolerance | OD Tolerance | Comments |

|---|---|---|---|

| Standard bronze bearing | ±0.02 mm | ±0.03 mm | Lower precision; suitable for low-speed, low-load applications |

| Oilless bronze bushing | +0/-0.01 mm | +0/-0.02 mm | High precision; suitable for high-speed, high-load operations |

5. Best Practices for Installation

- Always verify precision bronze bushing dimensions before installation.

- Ensure shaft and housing are free of burrs and debris.

- Use uniform hydraulic or mechanical pressing methods to avoid bushing distortion.

- Maintain proper interference fit to balance stability and ease of assembly.

- Regularly inspect installed bushings for wear, alignment, and lubrication effectiveness.

FAQs

1. What are the key dimensional tolerances for oilless bronze bushings?

The critical tolerances include ID +0/-0.01 mm, OD +0/-0.02 mm, and length ±0.05 mm. These tight tolerances ensure proper load distribution, smooth rotation, and optimal self-lubricating performance.

2. How should press-fit oilless bronze bushings be installed?

Use uniform hydraulic or mechanical presses, maintain axial alignment ±0.02 mm, and apply an interference fit of 0.01–0.03 mm. Avoid excessive interference to prevent deformation.

3. What are the surface roughness requirements?

The inner diameter of the bushing should have Ra 0.2–0.4 μm, the mating shaft Ra 0.2–0.8 μm, and the housing bore Ra ≤1.6 μm. Proper surface finish minimizes friction and wear.

4. How do oilless bronze bushings compare with standard cylindrical bronze bearings?

Cylindrical bronze bearing tolerances are generally looser (ID ±0.02 mm, OD ±0.03 mm). Oilless bronze bushings require tighter tolerances for high-speed, high-load applications, enhancing performance and longevity.

5. Are there maintenance considerations for press-fit oilless bronze bushings?

While self-lubricating, periodic inspection is recommended for high-load or high-temperature environments. Check for alignment, wear, and surface condition to ensure optimal performance.