-

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing -

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing -

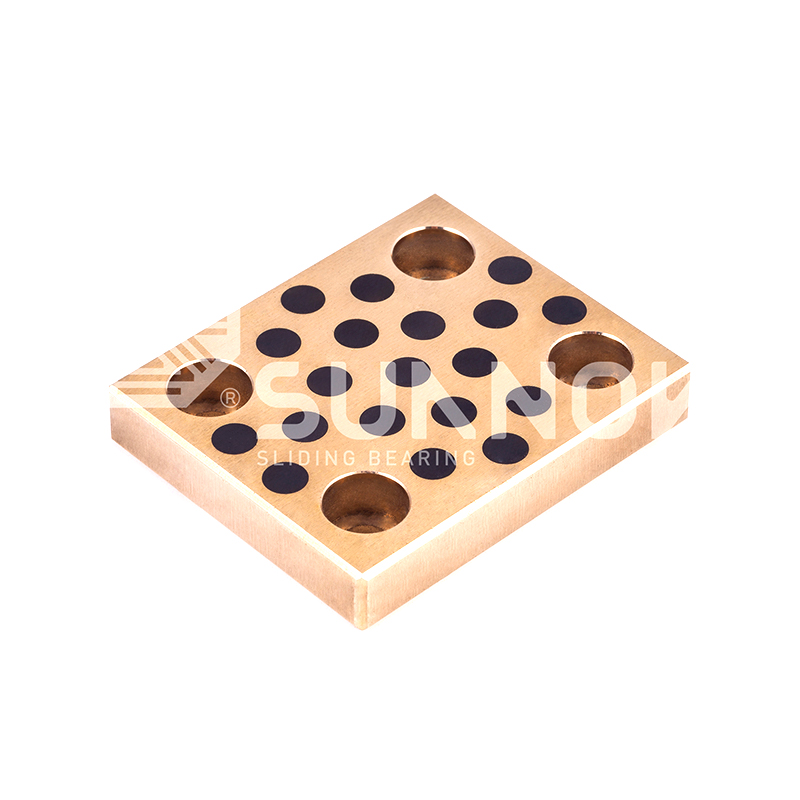

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate -

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing -

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush -

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers -

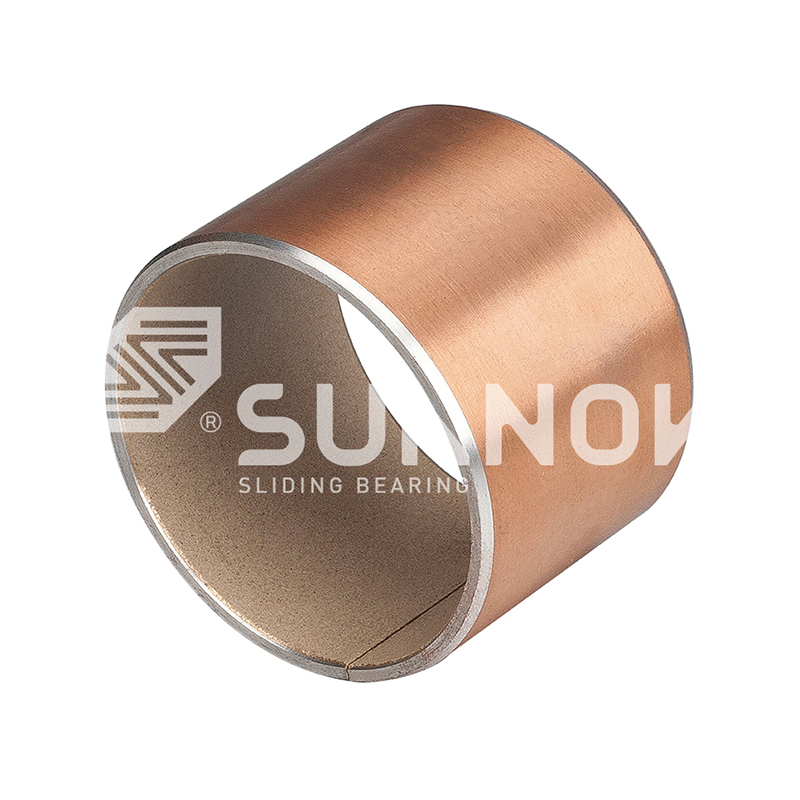

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

Why are Self Lube Bearings the Best Choice for Extreme Environments Where Manual Lubrication is Impossible?

Industry News-- 1 1. The Mechanics of Maintenance-Free Operation in Inaccessible Areas

- 2 2. Material Integrity: The Role of Centrifugal Casting in Extreme Loading

- 3 3. Performance in High-Temperature and Corrosive Environments

- 4 4. Custom Engineering and Design Flexibility

- 5 Frequently Asked Questions (FAQ)

- 6 Industry References

In modern industrial engineering, mechanical systems are increasingly deployed in unreachable or hazardous locations—from deep-sea valves and aerospace actuators to high-temperature smelting furnaces. In these scenarios, traditional grease-dependent systems fail due to lubricant evaporation or accessibility constraints. This is where self lube bearings provide a definitive solution. Zhejiang Shuangnuo Bearing Technology Co., Ltd., a professional manufacturer with nearly 10 years of R&D experience, specializes in the centrifugal and continuous casting of high-grade copper alloys. Our integrated production process ensures that every self lube bearing is engineered from the raw material level to withstand the most demanding operational stressors without the need for manual intervention.

1. The Mechanics of Maintenance-Free Operation in Inaccessible Areas

A primary challenge for engineers is: how do self lube bearings work without external grease? Unlike standard bearings that require periodic lubrication to maintain a hydrodynamic film, self lube bearings utilize a "solid lubricant" mechanism. During operation, a micro-film of lubricant (such as graphite or PTFE) is transferred from the bearing surface to the shaft, effectively reducing friction through a dry-sliding interface. This characteristic is critical for maintenance free self lubricating bushings used in heavy machinery where downtime for lubrication is economically prohibitive.

While traditional bearings suffer from "dry start-up" wear, self lube bearings provide immediate lubrication, ensuring structural integrity even after long periods of inactivity.

| Feature | Self Lube Bearings | Traditional Grease-Lubricated Bearings |

| Lubrication Method | Internal solid lubricants (Graphite/PTFE) | External grease or oil injection |

| Maintenance Requirement | Zero (Fit-and-forget) | High (Regular schedule required) |

| Risk of Seizure | Low (Self-healing lubricant film) | High (If grease dries or leaks) |

2. Material Integrity: The Role of Centrifugal Casting in Extreme Loading

In extreme environments, the base material of the bearing must support high PV (Pressure-Velocity) values. A frequent technical inquiry is: what is the load capacity of bronze self lubricating bearings? At Zhejiang Shuangnuo, we utilize centrifugal casting for our brass, aluminum bronze, and tin bronze alloys. This process creates a high-density grain structure free of gas holes and inclusions, which is essential for self lube bearings operating under heavy oscillatory loads. Our in-house spectrometer testing ensures that the chemical composition meets national standard grades before, during, and after the furnace.

Compared to standard metal mold casting, centrifugal casting offers significantly higher mechanical strength and wear resistance, making it the superior choice for high-pressure industrial applications.

| Technical Property | Centrifugal Cast Copper Alloy | Standard Sand Cast Alloy |

| Material Density | High (Uniform grain structure) | Lower (Potential for porosity) |

| Tensile Strength | Superior (Resistant to deformation) | Average |

| Hardness Consistency | Excellent across the entire component | Variable |

3. Performance in High-Temperature and Corrosive Environments

Extreme environments often involve temperatures that would cause standard oils to carbonize or wash away. Many procurement managers ask: are self lube bearings resistant to high temperatures and chemicals? Because the lubricants in self lube bearings are solid-state, they remain stable at temperatures exceeding 300°C. Furthermore, by using specific corrosion resistant self lubricating bearing materials like aluminum bronze, these components can operate in marine or chemical environments without the risk of galvanic corrosion or oxidation that typically plagues steel-backed alternatives.

- Thermal Stability: Solid lubricants do not undergo phase changes like liquid grease.

- Chemical Inertia: Sintered bimetallic and solid-inlaid products are designed to resist acidic or alkaline exposure.

- Spectrometer Testing: We verify material purity to ensure the self lube bearings provide the exact chemical resistance required by the customer's application.

4. Custom Engineering and Design Flexibility

Every extreme environment presents unique challenges, leading to the question: can I get custom designed self lube bearings for my project? Zhejiang Shuangnuo Bearing Technology Co., Ltd. adheres to a "moderation and harmony, integrity-based" philosophy, offering personalized tailor-made designs. With over 80 sets of advanced CNC machine tools and machining centers, we can produce self lube bearings with complex geometries—such as specific oil groove patterns or unique solid-inlay distributions—to optimize performance for a specific shaft speed or load vector.

In a self lube vs grease lubricated bearings comparison, the customizability of self-lubricating alloys allows for thinner wall thicknesses and more compact housing designs, which is a major advantage in aerospace and precision robotics.

Frequently Asked Questions (FAQ)

1. Do self lube bearings ever need to be replaced?

While they are "maintenance-free," self lube bearings are wear-parts. However, their service life is typically much longer than traditional bearings in harsh conditions because they are not prone to the failures caused by contaminated or insufficient grease.

2. Can these bearings operate under water?

Yes. Many of our self lube bearings, especially those using tin bronze or aluminum bronze bases, are specifically designed for submerged applications in hydro-power or marine equipment.

3. How do I choose the right solid lubricant inlay?

The choice between graphite, PTFE, or other molybdenum-based inlays depends on your operating temperature and load. Our technical team provides professional product application solutions to help you select the ideal configuration.

4. What is the maximum temperature these bearings can handle?

Depending on the alloy and the solid lubricant used, self lube bearings can operate effectively in environments ranging from -100°C to over 400°C.

5. How does Zhejiang Shuangnuo ensure material quality?

We insist on independent casting and use spectrometer testing three times during the production process. We also commission national testing agencies to verify mechanical properties and provide authoritative reports to our customers.

Industry References

- ISO 4379: Plain bearings — Copper alloy bushes.

- ASTM B271/B271M: Standard Specification for Copper-Base Alloy Centrifugal Castings.

- DIN 1850: Dimensions and tolerances for bushings and plain bearings.

- Technical Research Data: Zhejiang Shuangnuo Bearing Technology Co., Ltd. (2015-2025).