-

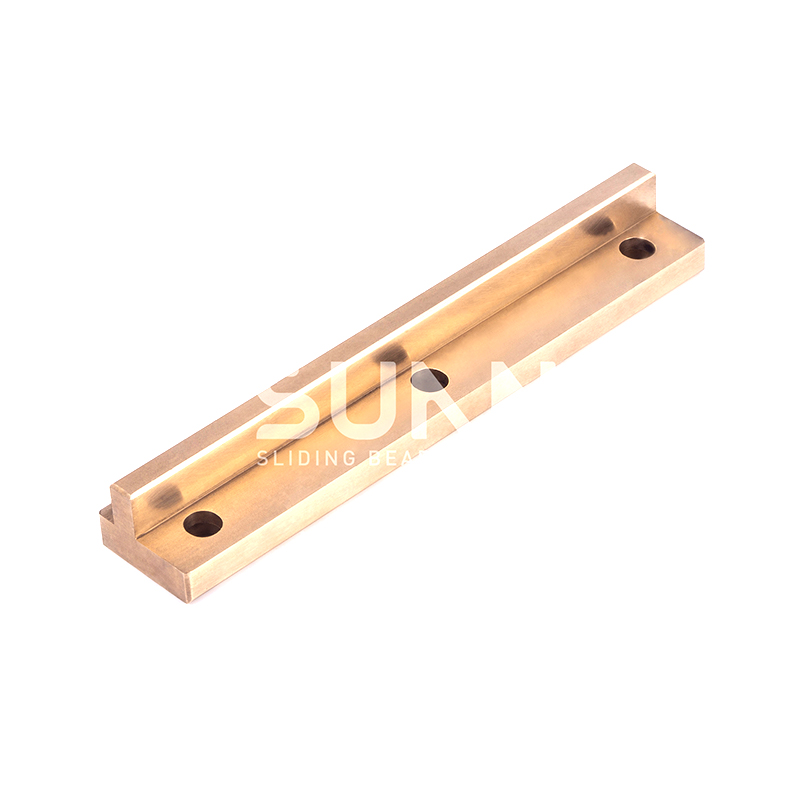

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components -

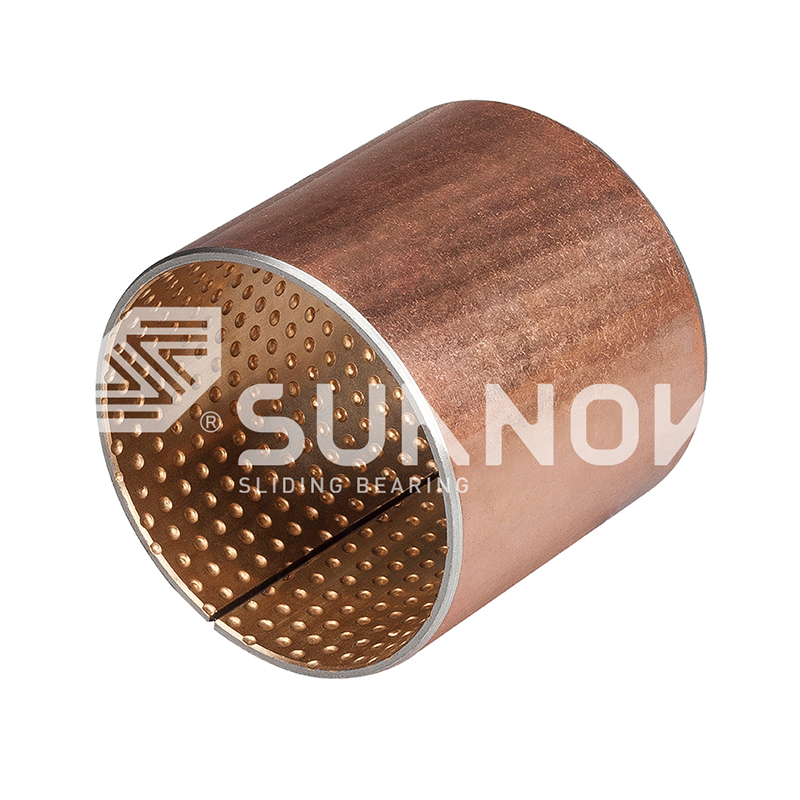

SF-1 Oilless Bearing Maintenance-Free SF-1W Wall Wrapped Lead-Free Bronze Bearing Oilless Bearing Bush

SF-1 Oilless Bearing Maintenance-Free SF-1W Wall Wrapped Lead-Free Bronze Bearing Oilless Bearing Bush -

-

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing -

SF-2 Boundary Lubricating Bearing SF-2Y Boundary Self-lubricating Bearing - Low Friction Dry Lubricant Bushings for Industrial Machinery

SF-2 Boundary Lubricating Bearing SF-2Y Boundary Self-lubricating Bearing - Low Friction Dry Lubricant Bushings for Industrial Machinery -

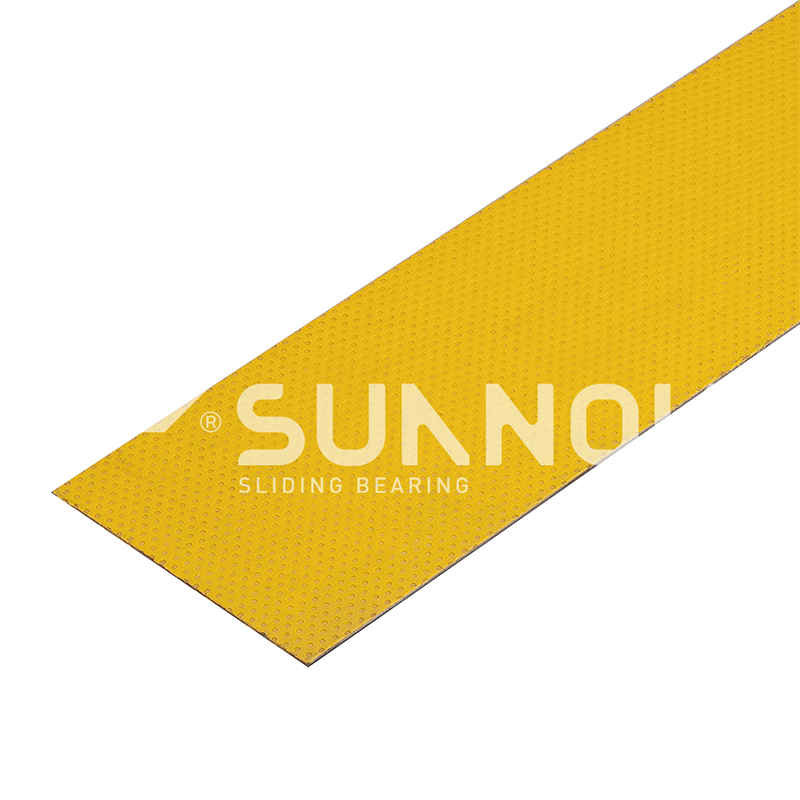

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE -

-

Why is Replacing Roller Bearings with a Bronze Graphite Bearing More Cost-Effective for Heavy-Duty Industrial Machinery?

Industry News-- 1 The Mechanical Advantages: Eliminating Complex Lubrication Systems

- 2 Thermal Stability and Load Bearing Capacity in Extreme Environments

- 3 Long-Term ROI: Maintenance-Free Operation and Component Life

- 4 Conclusion: A New Star in Self-Lubricating Technology

- 5 Engineering Standard: Matching Copper Alloys to Environmental Stress

- 6 Frequently Asked Questions (FAQ)

- 7 Industry References

In the high-stress environments of heavy-duty industrial machinery, the choice of bearing technology dictates not only the uptime of the equipment but also the long-term operational expenditure (OPEX). While roller bearings have traditionally been the default choice for rotational motion, engineers are increasingly turning to the Bronze graphite bearing as a superior, cost-effective alternative. Zhejiang Shuangnuo Bearing Technology Co., Ltd., a specialist in self-lubricating copper alloy products with nearly 10 years of R&D experience, provides high-performance solutions through advanced centrifugal and continuous casting. By integrating integrated production from raw material casting to CNC machining, we ensure that our high temperature graphite plugged bronze bearings meet the rigorous standards of global industrial applications.

The Mechanical Advantages: Eliminating Complex Lubrication Systems

The primary cost driver in roller bearings is the necessity for constant, external lubrication to prevent rolling element fatigue. In contrast, a self-lubricating bronze bush for heavy loads utilizes solid graphite plugs embedded within a high-strength copper alloy matrix. As the shaft rotates, a microscopic film of graphite is transferred to the mating surface, creating a permanent, dry lubrication layer. This eliminates the need for expensive grease pumps and manual maintenance intervals. While roller bearings are prone to catastrophic failure if the lubrication film is breached, maintenance-free bronze graphite bushings provide a fail-safe operation under boundary lubrication conditions.

| Technical Metric | Standard Roller Bearing | Bronze Graphite Bearing |

| Lubrication Method | Active (Requires grease/oil pumps) | Passive (Self-lubricating solid plugs) |

| Failure Mode | Seizure or spalling upon lube failure | Gradual wear; self-healing film |

| System Complexity | High (Seals, lines, reservoirs) | Low (Stand-alone component) |

Thermal Stability and Load Bearing Capacity in Extreme Environments

Industrial machinery often operates under extreme thermal gradients where standard bearing steels lose their temper and lubricants carbonize. Utilizing high temperature graphite plugged bronze bearings allows for stable operation in environments exceeding 300°C, temperatures that would typically cause roller bearing seals to melt and grease to liquefy. Furthermore, for oscillating or low-speed applications, the surface area contact of a solid lubricant embedded bronze bearing distributes loads more evenly than the line contact of roller elements, significantly reducing the risk of "brinelling" or surface indentation under heavy static loads.

Comparative Thermal and Load Performance

The structural integrity of Zhejiang Shuangnuo's products is guaranteed by spectrometer testing at three stages of the furnace process, ensuring the alloy composition is optimized for specific mechanical properties.

| Operating Condition | Steel Roller Bearing | Bronze Graphite Bearing (Shuangnuo) |

| Temperature Limit | Typically < 150°C (Grease limited) | Up to 400°C (Material dependent) |

| Load Distribution | Point/Line contact (High stress) | Full surface contact (Low stress) |

| Vibration Damping | Poor (Metal-on-metal impact) | Excellent (Alloy matrix absorption) |

Long-Term ROI: Maintenance-Free Operation and Component Life

The transition to maintenance-free bronze graphite bushings represents a strategic shift in maintenance philosophy from reactive to proactive. Roller bearings require scheduled downtime for lubrication and eventual replacement of worn rollers and cages. Because a Bronze graphite bearing has no moving internal parts, the risk of mechanical breakage is virtually non-existent. At Zhejiang Shuangnuo, we utilize more than 80 sets of advanced CNC machine tools to provide custom size bronze graphite sleeves for industrial use, ensuring a precision fit that further extends the life of the housing and the shaft, leading to a much lower total cost of ownership over the machine's lifecycle.

- Reduced Downtime: No lubrication stops required, increasing machine availability.

- Hardware Savings: Elimination of seals, grease nipples, and complex housing requirements.

- Environmental Impact: Zero grease leakage ensures a cleaner work environment and compliance with environmental regulations.

Conclusion: A New Star in Self-Lubricating Technology

For B2B procurement and engineering teams, the shift toward self-lubricating technology is an economic imperative. By choosing a Bronze graphite bearing from Zhejiang Shuangnuo Bearing Technology Co., Ltd., you are investing in a product that is monitored from raw material casting to finished part. Our commitment to "integrity-based" business ensures that we provide personalized, tailor-made designs that solve the specific friction challenges of your heavy-duty machinery.

Engineering Standard: Matching Copper Alloys to Environmental Stress

The performance of high temperature graphite plugged bronze bearings is not only dependent on the graphite plugs but also on the chemical stability of the base alloy. At Zhejiang Shuangnuo, we utilize centrifugal and continuous casting to ensure a dense grain structure, which is vital when the bearing is exposed to corrosive media or extreme mechanical pressures.

1. Aluminum Bronze (CuAl10Fe3) vs. Tin Bronze (CuSn12)

Aluminum bronze is the engineering choice for high-load, high-impact applications due to its superior tensile strength. Conversely, Tin bronze offers exceptional corrosion resistance, especially in marine environments, making it the standard for custom size bronze graphite sleeves for industrial use in the offshore and chemical industries.

| Property | Aluminum Bronze (ZCuAl10Fe3) | Tin Bronze (ZCuSn12) |

| Tensile Strength | ≥ 500 MPa (Superior load capacity) | ≥ 260 MPa (Moderate load) |

| Hardness (HB) | 130 - 180 (High wear resistance) | 80 - 110 (Shaft friendly) |

| Corrosion Resistance | Good (Standard environments) | Excellent (Seawater / Acids) |

2. High-Temperature Thresholds and Thermal Expansion

In high temperature graphite plugged bronze bearings, the difference in thermal expansion between the bronze and the graphite must be managed. Brass-based alloys (like ZCuZn25Al6Fe3Mn3) offer an excellent balance of high strength and lower cost for temperatures up to 300°C, while specialized Aluminum Bronzes can maintain structural integrity up to 400°C.

- Thermal Stability: Spectrometer testing ensures that the material composition remains within 0.1% of the target, preventing "softening" at high operational temperatures.

- Shaft Compatibility: We recommend a shaft hardness of HRC 45+ when using Aluminum Bronze bases to prevent shaft wear.

- Lubricant Coverage: Our CNC machining centers can customize the graphite plug pattern (e.g., staggered or linear) to maximize the lubricating film for specific oscillating angles.

3. Integrated Production and Quality Verification

Because we implement integrated production from raw material to finished product, Zhejiang Shuangnuo can provide authoritative test reports on both material composition and mechanical properties. This is critical for B2B customers who require maintenance-free bronze graphite bushings that must comply with strict safety and performance regulations in heavy-duty mining or construction machinery.

| Application Environment | Recommended Base Alloy | Primary Benefit |

| Mining / Earthmoving | Aluminum Bronze | Resistance to heavy impact and debris. |

| Marine / Hydroelectric | Tin Bronze | Long-term resistance to salt and cavitation. |

| Steel Mills / Furnaces | High-Strength Brass | Cost-effective thermal stability at high temperatures. |

4. Personalized Customization Philosophy

As a "new star" in the domestic industry, we don't just sell parts; we provide application solutions. Our personalized tailor-made design process ensures that the Bronze graphite bearing you receive is perfectly matched to your machine's unique load profile and environmental exposure.

Frequently Asked Questions (FAQ)

- Q1: Can a Bronze graphite bearing handle the same speeds as a roller bearing?

A: While roller bearings excel at high-speed applications, self-lubricating bronze bush for heavy loads is superior for high-load, low-to-medium speed, or oscillating movements where roller bearings often fail due to lack of a hydrodynamic film. - Q2: How does the "self-lubricating" mechanism actually work?

A: The friction between the shaft and the Bronze graphite bearing releases graphite particles from the plugs. These particles fill the microscopic asperities of the shaft, creating a smooth film that reduces the friction coefficient to as low as 0.05. - Q3: Is the material composition verified for heavy-duty use?

A: Yes. At Zhejiang Shuangnuo, we use spectrometer testing three times during the casting process and regularly commission national testing agencies to verify mechanical properties. - Q4: Are these bearings suitable for underwater or wet applications?

A: Absolutely. Our maintenance-free bronze graphite bushings are excellent in water or corrosive environments where standard grease would be washed away, provided the correct bronze alloy (like tin bronze or aluminum bronze) is selected. - Q5: Can I get a customized size for an older machine?

A: Yes. We specialize in custom size bronze graphite sleeves for industrial use, utilizing our machining centers to produce parts tailored to your specific equipment dimensions.

Industry References

- ASTM B271 - Standard Specification for Copper-Base Alloy Centrifugal Castings.

- ISO 4382 - Plain Bearings: Copper Alloys for Cast Solid Plain Bearings.

- Society of Tribologists and Lubrication Engineers (STLE) - Research on Solid Lubricant Embedded Bearings.

- National Standard of China (GB/T) - Standards for Self-Lubricating Bearing Compositions.