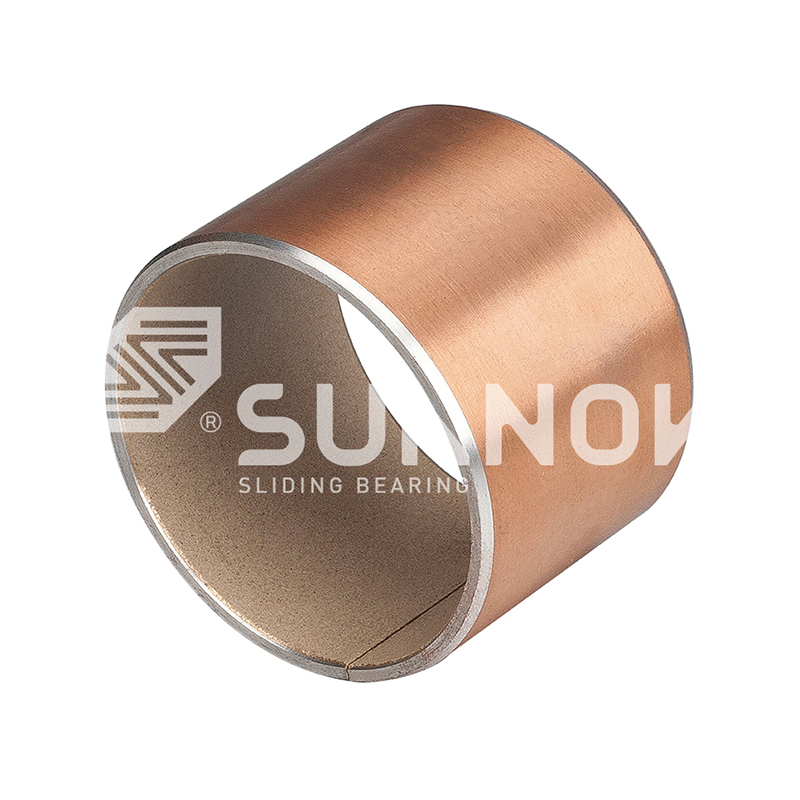

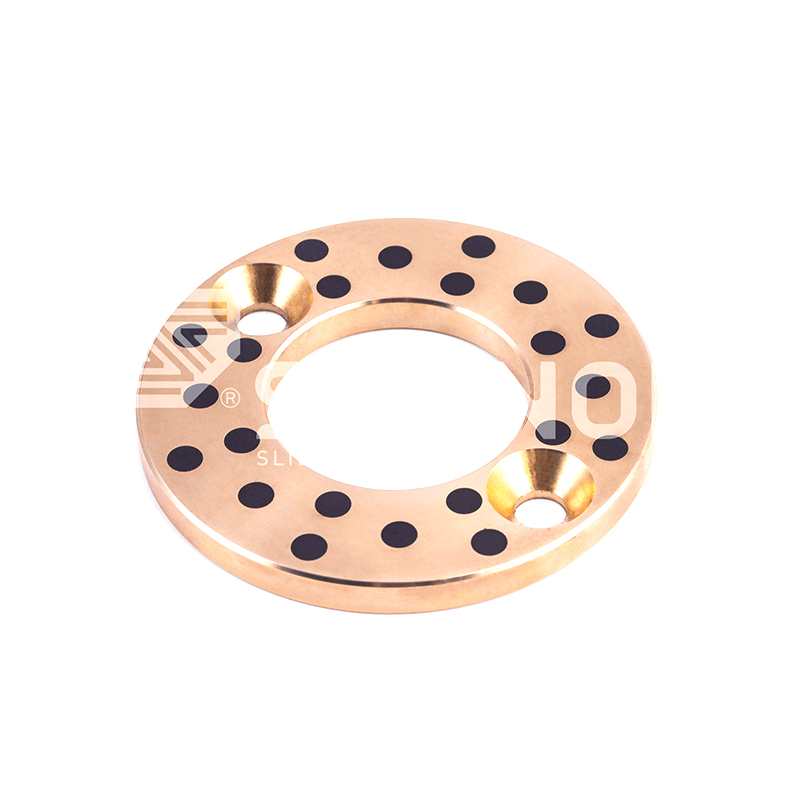

SF-1P is a high-performance self-lubricating composite bearing bushing designed for reciprocating motion and high-load low-speed applications. With bronze matrix and embedded solid lubricant, it can operate stably for a long time without external lubrication, significantly reducing maintenance costs and extending equipment life.

1. Excellent self-lubricating performance

Adopting PTFE/graphite composite lubrication layer, the friction coefficient is as low as 0.04~0.08, no external refueling is required, avoiding the risk of contamination.

Especially suitable for environments with difficult maintenance or limited lubrication (such as food machinery, cleaning equipment).

2. High strength and wear resistance

The bronze matrix (CuSn8P) provides high load-bearing capacity (static load ≥250MPa, dynamic load ≥140MPa).

The surface lubrication layer is evenly distributed, and the wear rate is reduced by more than 50% compared with traditional copper sleeves.

3. Corrosion resistance and wide temperature adaptability

Can withstand -200°C~+280°C temperature range, suitable for extreme working conditions (such as refrigeration equipment, high-temperature transmission systems).

Resistant to chemical corrosion, suitable for humid, acidic and alkaline environments.

4. Reduce overall costs

Maintenance-free design reduces downtime and lubrication costs.

The life span can reach 3~5 times that of ordinary bearings, significantly reducing the replacement frequency.

Why choose SF-1P?

Reduce maintenance: no lubrication is required, saving labor and consumables costs.

Improve reliability: avoid sudden failures caused by insufficient lubrication.

Strong compatibility: can directly replace traditional copper sleeves without structural modification.