-

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing -

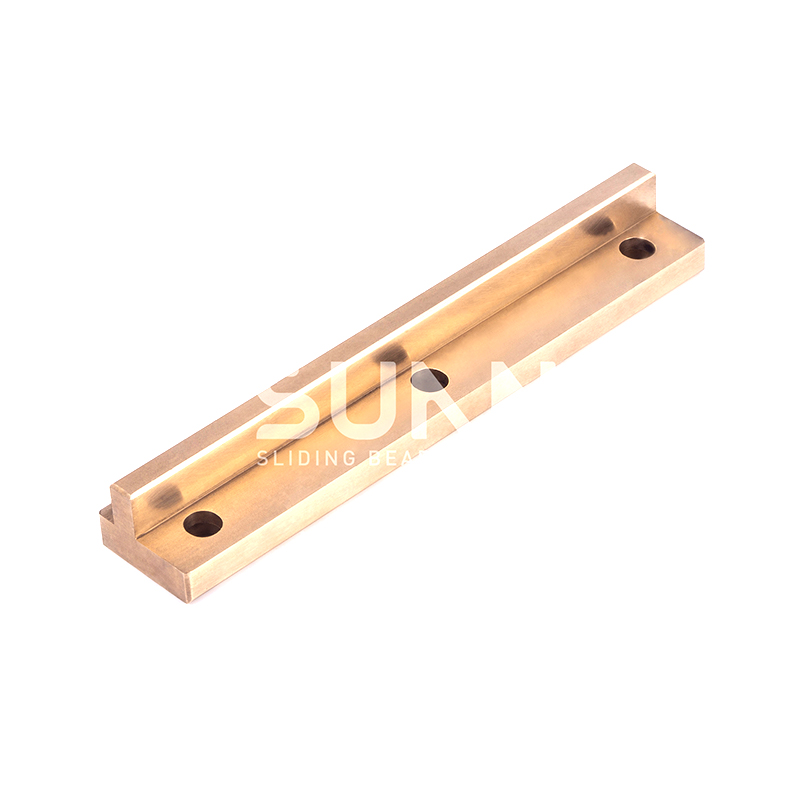

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components -

JDB Solid-lubricating Bearing JDB-5 Steel Embedded Wear Resistant Solid-lubricating Bearing

JDB Solid-lubricating Bearing JDB-5 Steel Embedded Wear Resistant Solid-lubricating Bearing -

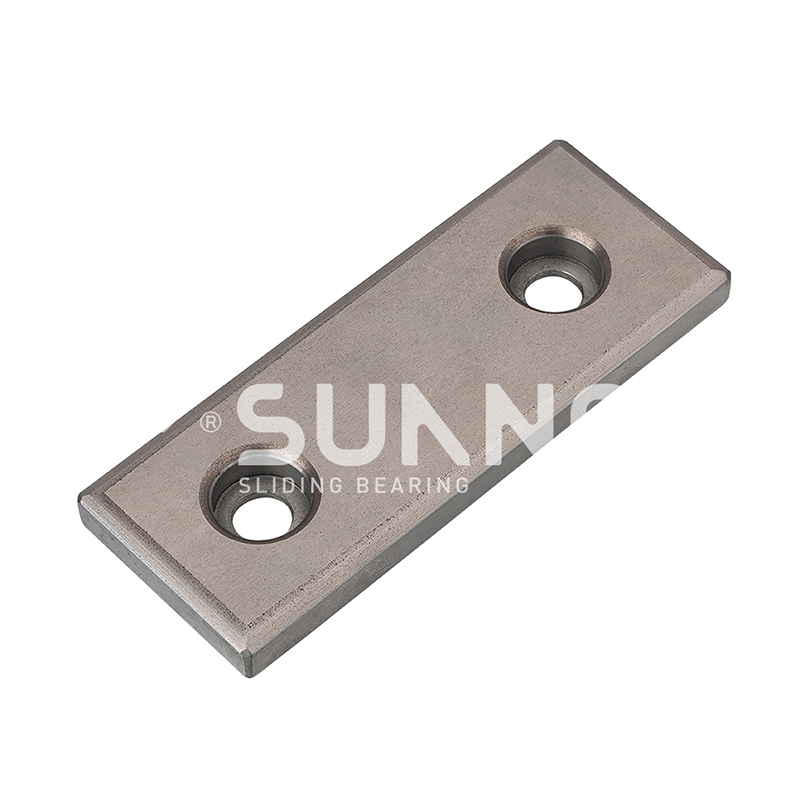

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications -

-

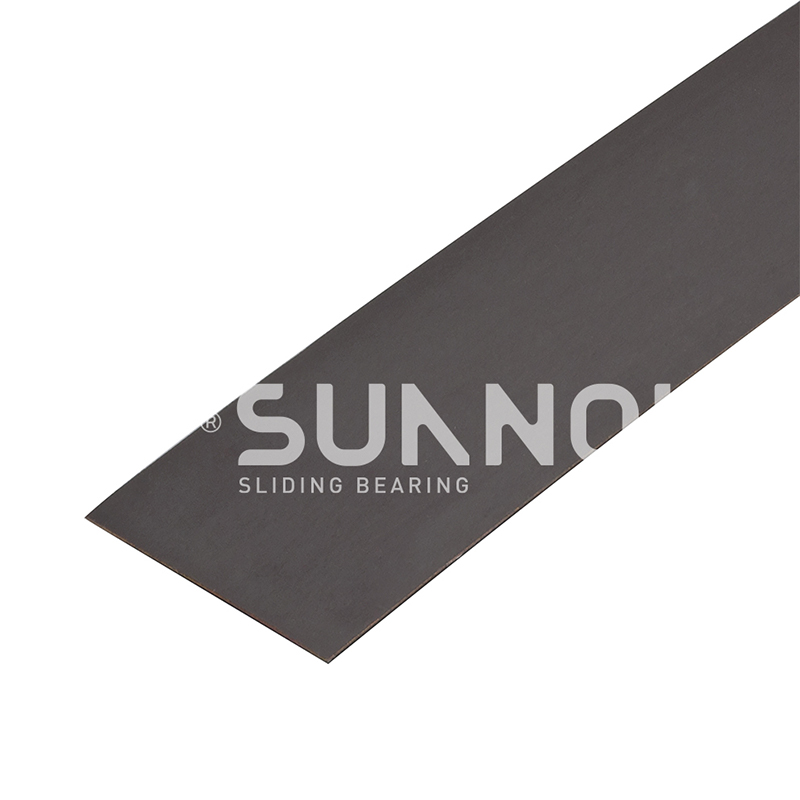

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip -

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers -

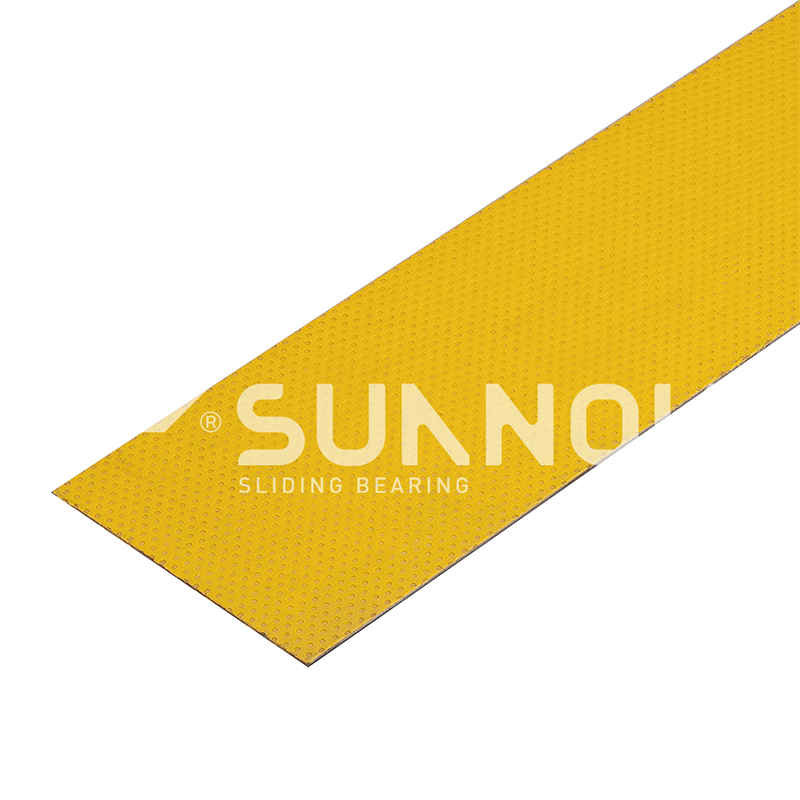

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

Why is the Transfer Film Mechanism of a self lubrication bearing Critical for Maintenance-Free Operation?

Industry News-In high-load and low-speed industrial applications, the transition toward maintenance-free components has prioritized the engineering of the self lubrication bearing. Unlike traditional hydrodynamic bearings that rely on a continuous external supply of oil or grease, self-lubricating systems operate on the principle of a "transfer film." This microscopic layer of lubricant is deposited from the bearing onto the mating shaft during initial motion, effectively substituting fluid lubrication with a solid-state boundary. Zhejiang Shuangnuo Bearing Technology Co., Ltd. has spent nearly a decade perfecting this technology. By utilizing centrifugal and continuous casting for our copper alloys—including brass, aluminum bronze, and tin bronze—we ensure a superior metallurgical base for solid lubricant embedded bushings. Our integrated production, from raw material casting to CNC precision machining, allows us to monitor material composition via spectrometer testing, ensuring that the transfer film mechanism functions flawlessly in heavy-duty environments.

1. The Physics of the Transfer Film Formation

The transfer film is a sacrificial layer of solid lubricant (typically graphite or PTFE) that fills the microscopic asperities of the mating steel shaft. As the self lubrication bearing begins its rotational or oscillating movement, frictional heat and shear forces release the embedded lubricant. This process creates a smooth, low-friction interface where the primary contact is lubricant-on-lubricant rather than metal-on-metal. According to the 2024-2025 tribology research published by the Society of Tribologists and Lubrication Engineers (STLE), the efficiency of this film formation is the single most important factor in determining the wear rate of maintenance free bronze sleeve bearings. Without a stable transfer film, the system reverts to dry sliding, leading to rapid adhesive wear and galling.

Source: STLE: Advances in Solid Lubrication and Transfer Film Dynamics 2024

Comparison: Boundary Lubrication vs. Solid Transfer Film

Traditional boundary lubrication requires a constant fluid film to prevent contact, while the solid transfer film mechanism provides a persistent dry barrier that remains effective even after long periods of inactivity.

| Feature | Traditional Grease Lubrication | Solid Inlaid Self-Lubricating Bearing |

| Maintenance Requirement | High; requires periodic re-greasing. | Zero; maintenance-free for its lifecycle. |

| Load Capacity | Limited by the film strength of the oil. | Very High; supported by copper alloy matrix. |

| Environmental Impact | Risk of leakages and contamination. | Clean; no fluid lubricants used. |

2. Material Composition and Film Stability

The quality of the transfer film is directly tied to the mechanical properties of the backing material. At Zhejiang Shuangnuo, our high load oilless bearing for construction machinery utilizes high-strength brass or aluminum bronze cast in-house. A robust metal matrix is necessary to support the solid lubricant embedded bushings under extreme pressure. If the metal is too soft, the lubricant pockets may deform; if too hard, the shaft may suffer abrasive wear before the film is established. Industry standards like ISO 4379:2024 emphasize that the coefficient of friction in self-lubricating systems is heavily dependent on the uniformity of the solid lubricant distribution within the metal mold casting.

Source: ISO 4379:2024 - Plain Bearings: Copper Alloy Bushes Technical Specifications

3. Mitigating Wear in Harsh Environments

In "maintenance-free" scenarios, the bearing must withstand dust, moisture, and high temperatures. A self lubrication bearing engineered with sintered bimetallic technology or solid inlays is designed to "self-heal." If the transfer film is scratched by debris, the ongoing movement of the shaft against the bearing automatically replenishes the lubricant layer from the internal reservoirs. This makes corrosion resistant self lubricating flange bearings ideal for maritime or offshore applications where traditional lubricants would be washed away or degraded by salt spray.

Comparison: Performance in Contaminated Environments

While grease-lubricated bearings trap abrasive particles in the lubricant, self-lubricating bearings with transfer films tend to push particles into the lubricant pockets or maintain a surface that is less prone to particle adhesion.

| Condition | Grease Lubricated Bearing | Self-Lubricating Copper Alloy Bearing |

| Dust/Grit Resistance | Poor; creates a "grinding paste." | Better; solid surface is less tacky. |

| High Temp Performance | Degrades; oil thins and leaks. | Excellent; solid lubricants remain stable. |

| Start-Stop Friction | High (Stick-slip effect). | Low (Persistent transfer film). |

4. Specialized Solutions by Zhejiang Shuangnuo

Our commitment to quality at Zhejiang Shuangnuo starts at the furnace. We perform spectral analysis three times during the casting process to confirm the chemical signature of every batch. For B2B clients requiring specialized applications, we provide customized self lubricating bearings for industrial valves and other high-precision equipment. Our facility, equipped with over 80 sets of CNC machine tools and machining centers, ensures that the tolerances required for optimal transfer film development—typically within microns—are met consistently. This integrated approach from material production to finished product significantly shortens the production cycle for our global customers.

Conclusion: The Foundation of Reliability

The transfer film mechanism is the technological "heart" of the self lubrication bearing. It enables a transition from labor-intensive manual maintenance to automated, reliable, and clean industrial operations. By carefully selecting the base alloy and optimizing the solid lubricant inlay, Zhejiang Shuangnuo Bearing Technology Co., Ltd. provides the professional product application solutions necessary to thrive in today's demanding high-tech markets. As a rising star in the domestic industry, we continue to bridge the gap between material science and maintenance-free mechanical performance.

Frequently Asked Questions (FAQ)

- How long does the transfer film take to form? The transfer film usually forms during the first few dozen cycles of the self lubrication bearing, known as the "running-in" period.

- Are solid lubricant embedded bushings suitable for underwater use? Yes, the solid lubricants like graphite or specialized PTFE are highly resistant to water and can maintain a film even in submerged conditions.

- Can I use a self lubrication bearing with a stainless steel shaft? Absolutely. In fact, stainless steel shafts are often preferred for their corrosion resistance, and the transfer film will adhere well to a properly finished surface.

- What happens if the transfer film is damaged? The bearing is designed to be self-replenishing. As long as there is lubricant remaining in the pockets, the film will be restored during operation.

- Why does Zhejiang Shuangnuo use centrifugal casting? Centrifugal casting ensures a denser material structure and removes impurities, which is critical for the mechanical strength of maintenance free bronze sleeve bearings.