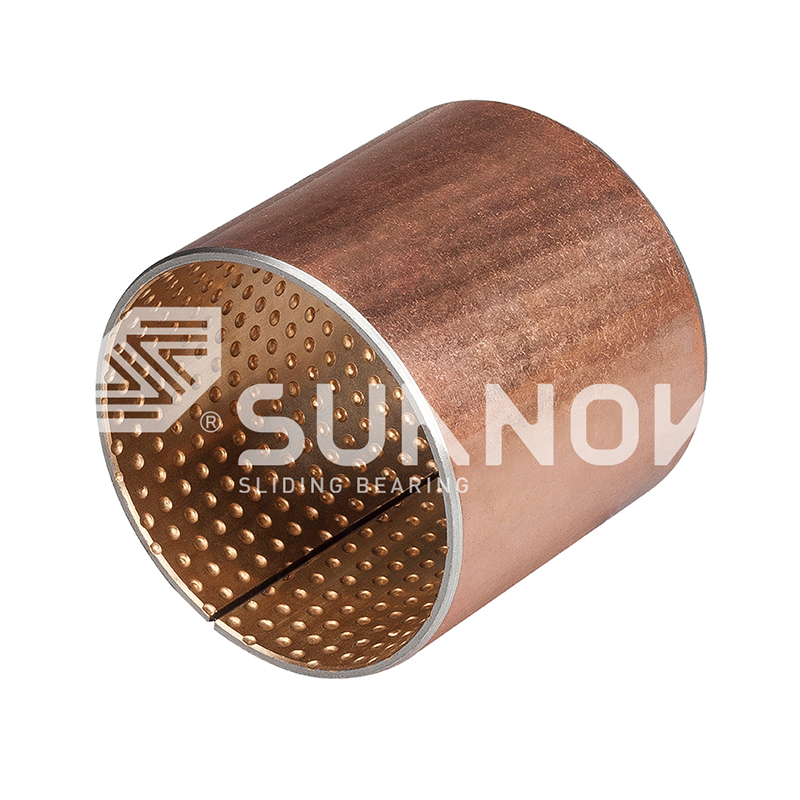

The JPBW/JPBF series is a maintenance-free, oil-free self-lubricating bearing that uses solid lubrication technology and is suitable for high-load, low-speed or swing motion scenarios. Its core advantages are that it does not require external lubrication, is wear-resistant and corrosion-resistant, and can work stably in extreme temperatures (-200°C to +300°C) and harsh environments (such as dust, vacuum, and moisture).

Typical application areas

Industrial machinery: spherical bearings for injection molding machines, stamping machines, and agricultural machinery.

Automotive industry: chassis components, suspension systems, and steering mechanisms.

Aerospace: wear-resistant parts of aircraft flaps and landing gear.

Energy equipment: wind turbine pitch bearings, turbine sealing rings.

Food and medical: conveyor belt bearings with no pollution requirements, sliding parts of medical equipment.

FAQ

Q1: What are the advantages of JPBW/JPBF bearings compared to traditional oil-lubricated bearings?

A1: Conventional bearings require regular oiling and maintenance, while JPBW/JPBF uses solid lubricants (such as graphite, PTFE) embedded in the metal substrate, which is lubricant-free for life. It avoids the risk of oil leakage, adapts to dust, high temperature or vacuum environment, has a longer life, and is particularly suitable for working conditions that are not easy to maintain, such as high-altitude equipment or clean workshops.

Q2: Can this bearing replace rolling bearings (such as ball bearings)?

A2: It depends on the scenario. JPBW/JPBF is more suitable for low-speed high-load or swinging motion (such as joint connection), while rolling bearings are suitable for high-speed rotation. For example, the bucket hinge of an excavator is more wear-resistant with solid lubricated bearings, but the motor spindle still needs rolling bearings. Speed, load and lubrication conditions must be considered comprehensively during design.

Q3: When used in the food industry, does it meet hygiene standards?

A3: Yes. JPBW/JPBF bearings have no oil pollution risk, and the material can pass FDA or EU 10/2011 certified lubricants (such as food-grade PTFE), suitable for food processing equipment, packaging machinery, etc. Its self-lubricating properties also reduce the frequency of cleaning and reduce the chance of contamination.