-

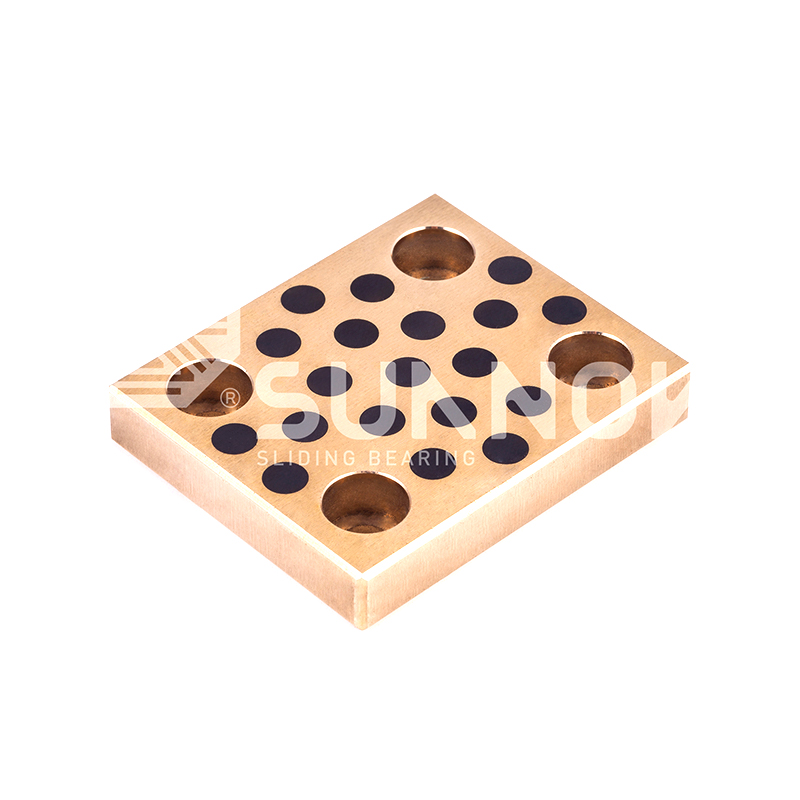

JDB Solid-lubricating Bearing GB61 Copper NAAMS Standard Flanged Solid-lubricating Bearing

JDB Solid-lubricating Bearing GB61 Copper NAAMS Standard Flanged Solid-lubricating Bearing -

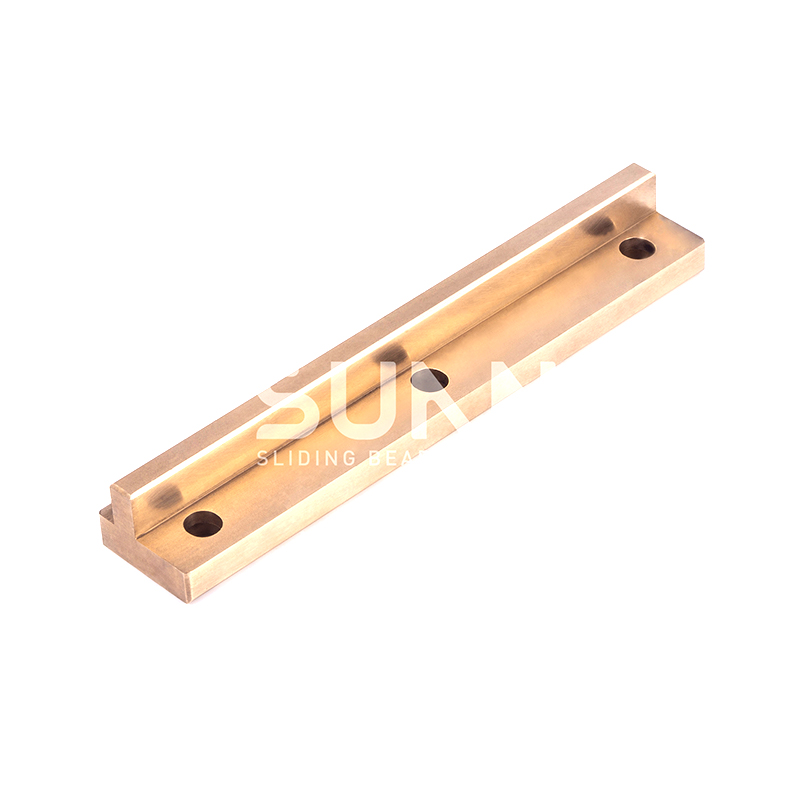

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate -

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components -

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing -

-

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications -

JF-800 Bi-metal Bearing JF-700 Bi-Metal Bearing Heavy Duty Self-Lubricating Sleeve Bushings

JF-800 Bi-metal Bearing JF-700 Bi-Metal Bearing Heavy Duty Self-Lubricating Sleeve Bushings -

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery

Solid-Lubricating Bronze Bearing: A Greaseless Solution for Modern Industry

Industry News-- 1 Introduction: Solid-Lubricating Bronze Bearing: A Greaseless Solution for Modern Industry

- 2 What is a Solid-Lubricating Bronze Bearing?

- 3

- 4 Applications and Advantages of Solid-Lubricating Bronze Bearings

- 5 How to Choose the Right Solid-Lubricating Bronze Bearing

- 6 Conclusion

- 7

- 8 Frequently Asked Questions (FAQ)

Introduction: Solid-Lubricating Bronze Bearing: A Greaseless Solution for Modern Industry

Traditional bearing systems rely on constant external lubrication, which often means regular oiling or greasing. This maintenance is not only time-consuming and labor-intensive but can also lead to problems in dusty, humid, or contaminated environments. The leakage or contamination of lubricants is a significant challenge, especially for industries with strict cleanliness requirements like food processing, medical equipment, and textiles.

To solve these problems, the Solid-Lubricating Bronze Bearing was developed. This is an innovative bearing technology that achieves self-sufficient operation without external lubrication by embedding solid lubricants (such as graphite, PTFE) evenly into a porous bronze matrix. This unique design allows the bearing to automatically release lubricating components onto the friction surface during operation, forming a stable lubricating film that effectively reduces friction and wear.

Comparison of Traditional Bearings and Solid-Lubricating Bronze Bearings

| Feature | Traditional Slide Bearings (Requires External Lubrication) | Solid-Lubricating Bronze Bearings |

| Lubrication Method | Requires regular addition of oil or grease | Internal solid lubricant is automatically released; no external lubrication needed |

| Maintenance Frequency | High (requires regular inspection and lubricant replenishment) | Low (virtually maintenance-free) |

| Contamination Risk | High (lubricant leakage can contaminate the environment or products) | Extremely low (no oil leakage, environmentally friendly) |

| Applicable Environments | Prone to failure in dusty or harsh environments; requires additional sealing | Works stably in dusty, humid, and other harsh environments |

| Starting Friction Coefficient | Relatively high (dry start) | Relatively low (solid lubricant is already present at startup) |

| Service Life | Highly dependent on lubrication maintenance; can be shortened by poor lubrication | Stable lubrication, minimal wear, longer service life |

| Total Cost of Ownership | High costs for maintenance, labor, and lubricants | Slightly higher initial investment, but very low long-term maintenance costs |

Through this comparison, it's clear that the Solid-Lubricating Bronze Bearing is not just a replacement but an advanced solution that significantly improves equipment reliability, lowers operating costs, and enhances environmental safety.

What is a Solid-Lubricating Bronze Bearing?

A Solid-Lubricating Bronze Bearing is a high-performance slide bearing that combines the strength of a metal matrix with the oil-free properties of a solid lubricant. It is a precision composite structure, not just a simple coating of lubricant on the surface. These bearings typically use sintered or cast bronze as a base, with solid lubricants like graphite, molybdenum disulfide (MoS2), or polytetrafluoroethylene (PTFE) embedded uniformly within or on their surface.

The core principle of its operation is that as the bearing runs, the heat generated by friction causes the solid lubricant embedded in the bronze matrix to be slowly and steadily released onto the bearing's surface. These solid lubricating particles form a thin, durable transfer film between the bearing and the shaft. This lubricating film is key to the bearing's Oil-less bearings capability. It effectively separates the friction surfaces, significantly reduces the friction coefficient, thereby minimizing wear and ensuring the bearing runs smoothly without external lubrication.

This design makes it an ideal Grease-free bronze bearing because it completely eliminates the need for lubricating oils and greases.

Comparison of Common Solid-Lubricating Bronze Bearing Types and Their Characteristics

| Type | Manufacturing Process | Lubricant Type | Main Advantages | Typical Applications |

| Cast Bronze Matrix with Embedded Plugs | Solid lubricant plugs (e.g., graphite) are cast or pressed into pre-machined holes | Graphite, Molybdenum Disulfide | High load capacity, wear resistance, suitable for heavy-duty, low-speed conditions | Heavy machinery, hydraulic engineering, construction equipment |

| Sintered Bronze Matrix with Impregnated Oil | Copper and tin powders are sintered at high temperatures to create a porous structure, then impregnated with oil | Lubricating oil (as initial lubrication) | Porous structure can absorb a large amount of lubricant, suitable for medium-speed, light-duty conditions | Household appliances, office equipment, automotive components |

| Composite Material (Multi-Layer Structure) | Steel backing with a sintered spherical bronze powder middle layer and a surface layer of PTFE and lead mixture | PTFE, Lead | Extremely low friction coefficient, excellent self-lubricating performance, suitable for high-speed, medium-duty conditions | Pumps, valves, automotive suspension systems |

Understanding these types and their characteristics helps in selecting the most suitable Solid-Lubricating Bronze Bearing solution for specific application needs.

GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing

Applications and Advantages of Solid-Lubricating Bronze Bearings

The unique performance of the Solid-Lubricating Bronze Bearing makes it an ideal choice for a wide range of demanding environments that require high reliability, low maintenance, and no contamination. It is not just a bearing but a versatile Self-lubricating bushing and Oilless slide plate, widely used in various sliding and rotational motion applications.

Core Application Areas

- Construction and Heavy Machinery: In the joints of excavators, cranes, and bulldozers, traditional lubricants are easily contaminated by dirt, dust, and water, leading to increased wear. Solid-Lubricating Bronze Bearings can work stably in these harsh environments, reducing maintenance and downtime.

- Hydraulic and Marine Engineering: On the pivots of water pumps, sluice gates, and underwater equipment, bearings are in contact with water or humid environments for long periods. The Oil-less bearings feature prevents lubricant contamination of the water, while their corrosion resistance is also fully utilized.

- Food and Medical Equipment: These industries have extremely high cleanliness requirements, where any lubricant leakage can contaminate products. Grease-free bronze bearings ensure equipment can operate safely without oil, meeting strict hygiene standards.

- Industrial Automation and Robotics: In automated production lines that require precise, contamination-free motion, Composite bearings provide stable friction performance, ensuring smooth movement of robot arms and conveyor belts.

Main Advantages

| Advantage Category | Specific Description | Value Gained |

| Reduced Maintenance | The inherent solid lubricant makes it a maintenance-free or low-maintenance solution, eliminating the need for regular oiling or greasing. | Lower Total Cost of Ownership (TCO). Reduces labor costs, lubricant consumption, and equipment downtime. |

| Increased Reliability | Traditional lubrication systems are prone to failure in harsh conditions (e.g., high temperatures, low temperatures, dust, humidity). The performance of the Solid-Lubricating Bronze Bearing is stable and unaffected by the environment, effectively reducing the failure rate. | Extends equipment lifespan and ensures the continuity and stability of the production line. |

| Environmentally Friendly | The oil-less and grease-free design completely eliminates the risk of lubricant leakage, which could contaminate the environment and products, especially in industries like hydraulic, food, and textile. | Enhances environmental compliance, creating a cleaner, safer work environment for the company. |

| High Load Capacity | The bronze matrix provides excellent mechanical strength, allowing it to withstand high loads and impact forces. At the same time, the use of solid lubricants ensures low friction and long life under heavy loads. | Meets demanding engineering requirements, performing excellently in heavy machinery applications. |

In summary, the advantage of the Solid-Lubricating Bronze Bearing is that through technological innovation, it transforms the maintenance burden and environmental risks of traditional lubricated bearings into its core competitiveness, providing modern industry with efficient, reliable, and environmentally friendly sliding solutions.

How to Choose the Right Solid-Lubricating Bronze Bearing

Choosing the right Solid-Lubricating Bronze Bearing is crucial to ensuring its optimal performance in an application. This requires a comprehensive consideration of multiple technical parameters and operating conditions to match the bearing's characteristics with specific needs.

Key Factors to Consider

- Load Type and Magnitude:

- Static Load: The force the bearing withstands when the equipment is stationary.

- Dynamic Load: The force the bearing withstands during equipment operation.

- Impact Load: A brief but powerful instantaneous force.

Selection Basis: Solid-Lubricating Bronze Bearings with a cast bronze matrix generally have higher strength and hardness, capable of withstanding greater static and dynamic loads, making them suitable for heavy machinery and construction equipment. For lighter loads, other types of composite Self-lubricating bushings might be more cost-effective.

- Operating Speed and PV Value:

- Operating Speed (V): The linear speed of the bearing surface.

- PV Value (Pressure x Velocity): The product of load (P) and speed (V), an important indicator of the bearing's working stress. A high PV value means the bearing needs to handle more heat and friction, requiring better lubrication performance.

Selection Basis: Different solid lubricant and matrix combinations can adapt to different PV value ranges. For example, PTFE-based composite Solid-Lubricating Bronze Bearings are generally suitable for high PV values and high-speed conditions, while graphite-embedded bearings are more suited for medium-to-low speed, heavy-duty conditions.

- Temperature and Environment:

- Temperature: The ambient temperature and the heat generated by the bearing itself. High temperatures can affect the performance of some solid lubricants, leading to failure.

- Environment: The presence of dust, moisture, corrosive chemicals, etc.

Selection Basis: In high-temperature environments, choose a Solid-Lubricating Bronze Bearing with heat-resistant graphite or a special alloy matrix. In humid or dusty environments, its oil-less and grease-free properties give it a natural advantage, but it is necessary to ensure the solid lubricant does not react chemically with substances in the environment.

Bearing Selection Parameter Comparison Table

| Feature | Graphite-Embedded Solid-Lubricating Bronze Bearing | PTFE Composite Solid-Lubricating Bronze Bearing | Molybdenum Disulfide-Embedded Solid-Lubricating Bronze Bearing |

| Base Material | Cast or sintered bronze | Sintered porous bronze | Cast or sintered bronze |

| Solid Lubricant | Graphite | Polytetrafluoroethylene (PTFE) and additives | Molybdenum Disulfide ($MoS_2$) |

| Load Capacity | High (suitable for heavy-duty, low-speed) | Medium (suitable for medium loads, high speed) | Medium (suitable for medium loads, high speed) |

| Friction Coefficient | Medium to Low | Extremely Low | Low |

| Temperature Range | Wide, can withstand high temperatures | Narrower, limited by PTFE's temperature resistance | Wide, suitable for high temperatures and vacuum environments |

| Typical Applications | Construction machinery, hydraulic engineering, heavy industry | Automotive components, office equipment, textile machinery | Aerospace, vacuum equipment, precision instruments |

By comparing these key parameters, engineers and designers can accurately select the most suitable Solid-Lubricating Bronze Bearing for specific applications, ensuring long-lasting reliability while achieving maintenance-free and oil-less operation.

Conclusion

The Solid-Lubricating Bronze Bearing represents a major advancement in modern slide bearing technology. It is not just a simple replacement but a high-efficiency, reliable, and environmentally friendly sliding solution provided by its unique composite material and self-sufficient lubrication mechanism.

Fundamentally, the core value of this bearing lies in its oil-less and grease-free characteristics. It completely changes the reliance of traditional bearings on external lubrication systems, simplifying complex maintenance tasks to require almost no intervention. This not only significantly reduces operating costs and labor input but also greatly enhances equipment reliability in dusty, humid, or extreme environments.

Comparison of Overall Value: Traditional Bearings vs. Solid-Lubricating Bronze Bearings

| Value Dimension | Traditional Lubricated Bearings | Solid-Lubricating Bronze Bearings |

| Economic Benefits | Requires long-term investment in lubricant costs and maintenance fees | Initial investment may be slightly higher, but long-term maintenance costs are very low, leading to a better total cost of ownership |

| Operational Efficiency | Prone to increased friction and reduced efficiency due to improper lubrication | Stable friction coefficient ensures smooth and efficient equipment operation |

| Environmental Impact | Risk of lubricant leakage, which can contaminate the environment and products | No oil leakage, completely environmentally friendly, suitable for industries with high cleanliness requirements |

| Reliability | Reliability is reduced by susceptibility to external environments (dust, water) | Can operate stably in harsh conditions, with significantly improved reliability |

| Design Flexibility | Requires space and channels to be reserved for the lubrication system | Compact structure simplifies mechanical design and saves space |

In conclusion, with its excellent performance, low maintenance needs, and environmental friendliness, the Solid-Lubricating Bronze Bearing is increasingly becoming an indispensable component in modern industrial design. It provides a solid foundation for automation, sustainable development, and high-reliability applications, and is an important driver for continued innovation in the future industrial sector.

Frequently Asked Questions (FAQ)

1. What are the main advantages of Solid-Lubricating Bronze Bearings?

The main advantages of Solid-Lubricating Bronze Bearings are their oil-less, maintenance-free, high reliability, and environmentally friendly characteristics. Compared to traditional bearings that require regular lubrication, they significantly reduce maintenance costs and downtime, and perform exceptionally well in dusty, humid, or contamination-prone environments. At the same time, their robust bronze matrix and internal solid lubricants ensure stable operation under heavy loads and complex conditions.

2. What key factors should be considered when choosing a Solid-Lubricating Bronze Bearing?

When selecting the right Solid-Lubricating Bronze Bearing, you need to consider a combination of the following key factors:

- Load Type and Magnitude: Determine the static, dynamic, or impact loads the bearing will bear.

- Operating Speed: The linear speed of the bearing surface affects friction and heat generation.

- Working Environment: Consider factors such as temperature, humidity, dust, and chemical corrosion.

- Material Combination: Based on the specific application, select the appropriate bronze alloy and solid lubricant type (e.g., graphite, PTFE) to achieve optimal performance.

3. What is unique about Zhejiang Shuangnuo Bearing Technology Co., Ltd.'s production of Solid-Lubricating Bronze Bearings?

Zhejiang Shuangnuo Bearing Technology Co., Ltd. is a manufacturer specializing in the production of various self-lubricating copper alloy products using centrifugal casting, continuous casting, metal mold casting, and other processes. Its main products include brass, aluminum bronze, tin bronze, and other products produced according to national standard grades. On this basis, it processes and produces various solid inlaid self-lubricating bearing products. At the same time, it uses sintering technology to produce bimetallic products and many other types of products. Since its establishment nearly 10 years ago, the company has focused on the research development, and production of various new self-lubricating bearings.

In the process of product production, our company has always insisted on independent casting production of raw materials to ensure the quality of products from the source; during the casting process, the whole process is monitored, and the finished product is tested by spectrometer three times before, in and after the furnace to confirm the material composition of the product. The national testing agency is regularly commissioned to test the material composition and mechanical properties of the product, and authoritative test reports can be provided to customers in need; the company implements integrated production from material to finished product processing and has more than 80 sets of advanced CNC machine tools, CNC lathes, machining centers, and other major equipment. The strong production capacity ensures that the material production is organized for customers for the first time, shortening the production cycle.