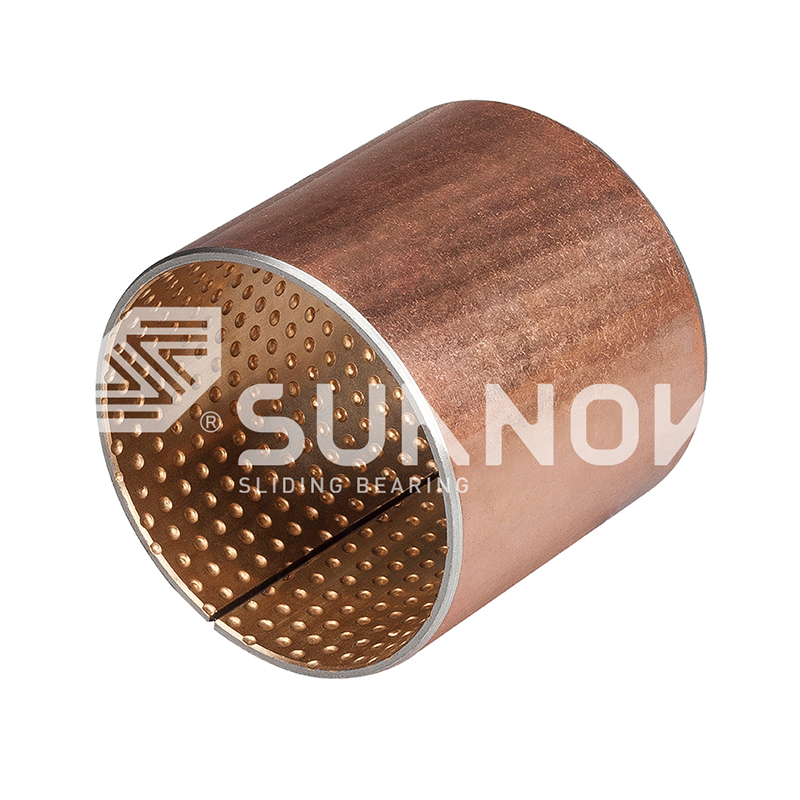

The SF-1B bronze bearing is engineered for high-load, low-friction applications, featuring a durable bronze matrix embedded with solid lubricants for maintenance-free, long-lasting performance. Ideal for industrial machinery, agricultural equipment, and heavy-duty transmission systems in high-temperature, high-pressure environments, it significantly reduces wear and energy consumption.

Key Advantages

1. Exceptional Load Capacity

The bronze alloy + steel-backed structure withstands over 30MPa dynamic load, offering 3x longer lifespan than standard bearings—perfect for heavy-duty machinery bearings.

2. Ultra-Low Friction Design

Pre-embedded graphite/PTFE lubricants achieve a friction coefficient of 0.04–0.08, minimizing startup torque for low-speed high-load bearing applications.

3. Self-Lubricating, Zero Maintenance

Patented solid-lubricant technology eliminates grease contamination, ideal for food-grade lubricant bearings or dusty environments.

4. High-Temperature & Corrosion Resistant

Operates in -200°C to +300°C ranges with anti-corrosion properties, meeting high-temperature high-pressure bearing demands.

5. Custom Solutions

Tailored sizes available, including wear-resistant bronze bushings for specialized equipment.

| Parameter |

Value/Feature |

| Base Material |

High-Strength Tin Bronze (CuSn8P) |

| Max Load |

30MPa (dynamic) / 60MPa (static) |

| Friction Coefficient |

0.04–0.08 |

| Temperature Range |

-200°C ~ +300°C |

| Lubrication |

Self-lubricating (graphite/PTFE) |

Applications

- Heavy-duty slow-speed bearings: Mining conveyors, port crane shafts

- High-temperature self-lubricating bearings: Steel mill rollers, heat treatment systems

- Corrosion-resistant bearing sleeves: Chemical pumps, marine equipment

- Food-grade oil-free bearings: Pharmaceutical machinery, packaging lines

- Long-life wear-resistant bushings: Agricultural harvesters, wind turbine gearboxes