-

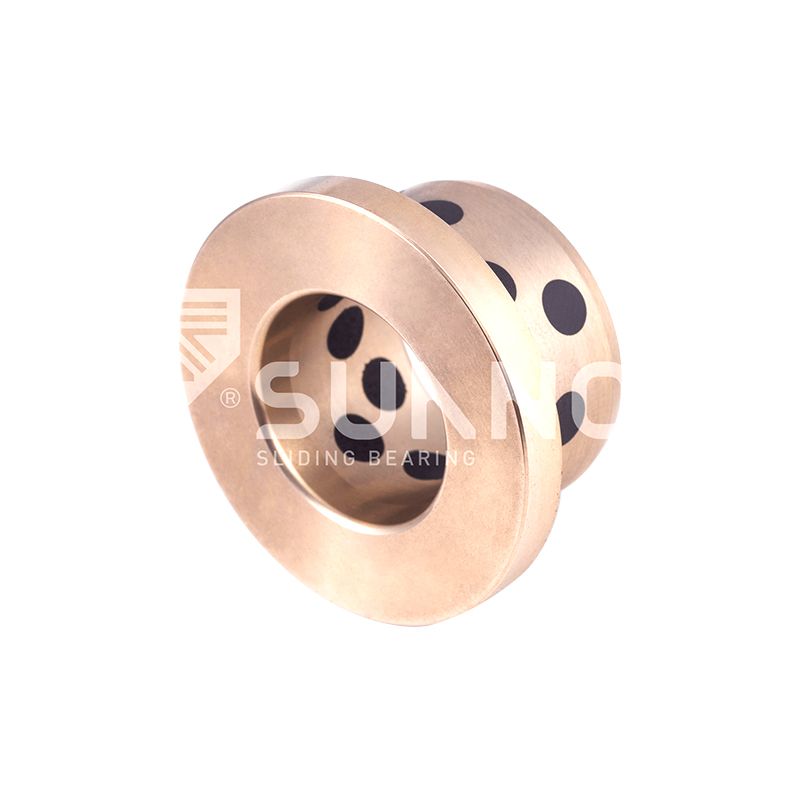

JDB Solid-lubricating Bearing JFBB Metric Self-lubricating Oilless Graphite Flanged Bearings Bushings

JDB Solid-lubricating Bearing JFBB Metric Self-lubricating Oilless Graphite Flanged Bearings Bushings -

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing -

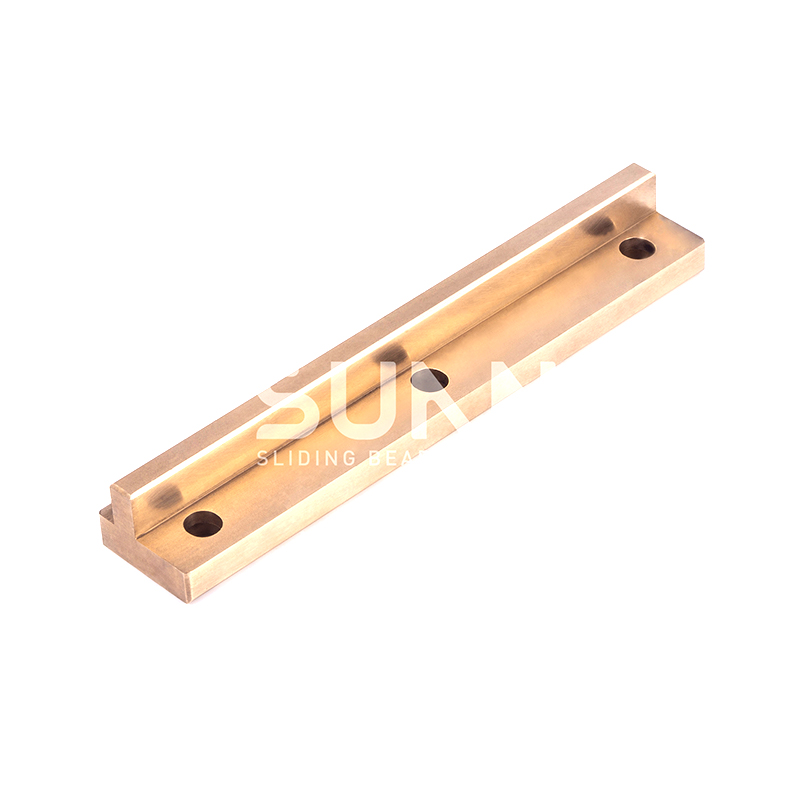

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate -

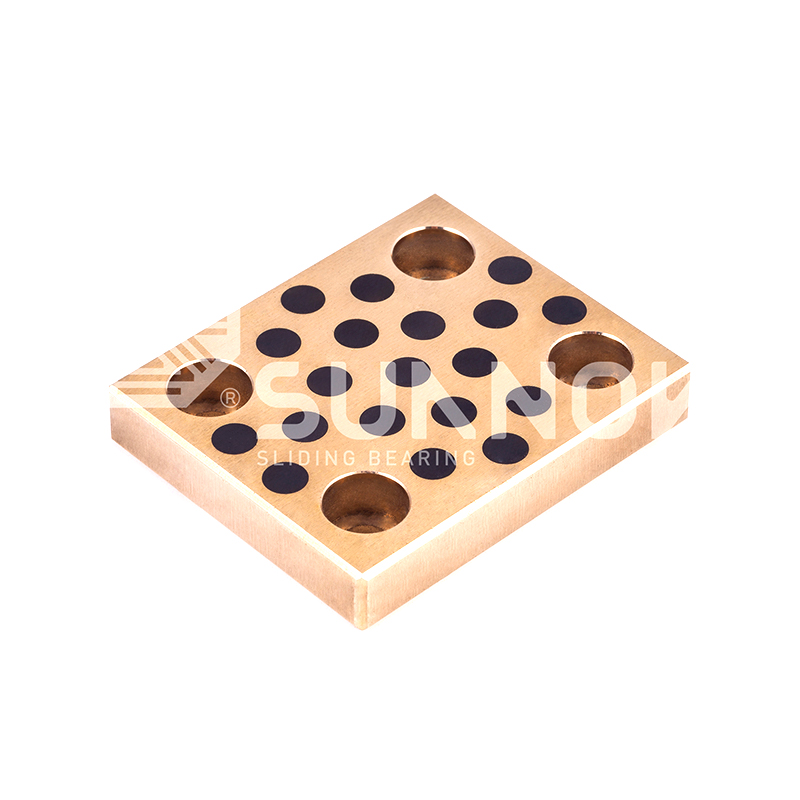

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components -

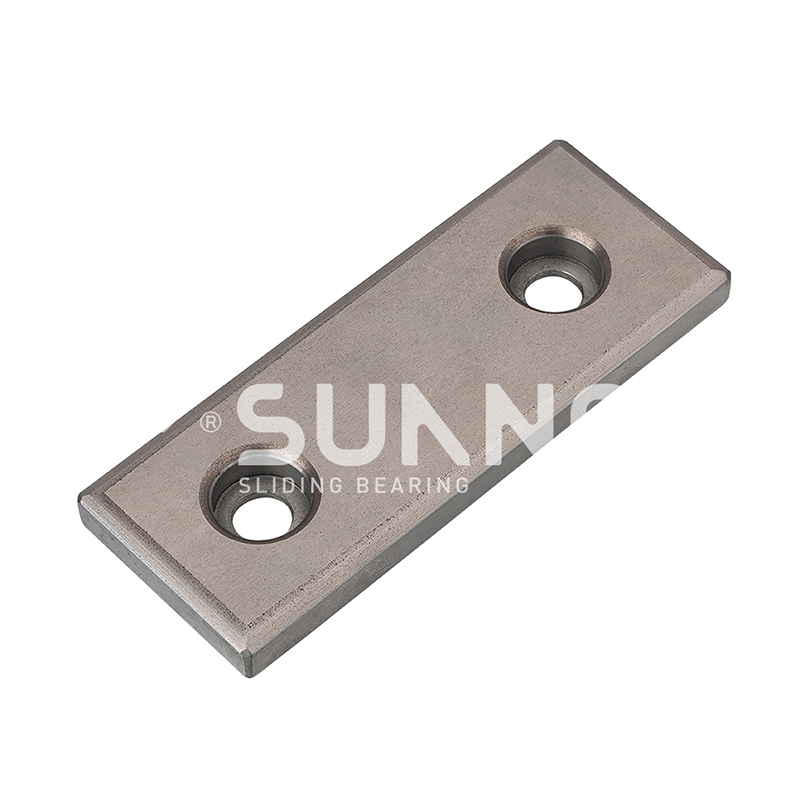

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications -

-

-

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing

How Self-Lubricating Copper Alloy Bearings Improve Performance and Durability

Industry News-Introduction to Self-Lubricating Copper Alloy Bearings

What are Self-Lubricating Copper Alloy Bearings?

Self-lubricating copper alloy bearings are designed to reduce friction and wear without the need for external lubrication. These bearings combine the inherent properties of copper alloys with self-lubricating materials, providing efficient solutions for various industrial applications. Unlike traditional bearings, which require regular lubrication maintenance, these self-lubricating bearings operate smoothly with minimal maintenance. The copper alloy composition ensures superior wear resistance and the ability to function in demanding conditions such as high temperatures and heavy loads.

The Importance of Bearings in Industrial Applications

Bearings are crucial components in various machinery, from motors to industrial machines. Their primary role is to minimize friction between moving parts, ensuring smooth operation and prolonging the lifespan of the equipment. Self-lubricating copper alloy bearings take this a step further by offering enhanced durability and performance, especially in environments where traditional bearings might fail. They are an ideal solution for industries that rely on high-performance machinery.

JFBB Metric Self-lubricating Oilless Graphite Flanged Bearings Bushings

Advantages of Self-Lubricating Copper Alloy Bearings

High Durability and Reduced Wear

One of the standout benefits of self-lubricating copper alloy bearings is their durability. These bearings can withstand high levels of wear and tear, even in harsh conditions, reducing the need for frequent replacements. The copper alloy material naturally resists corrosion, making it perfect for use in environments where moisture or chemicals might cause traditional bearings to degrade quickly.

- Resistant to corrosion and wear

- Longer lifespan, reducing downtime and replacement costs

- Better performance under high-load conditions

Maintenance-Free Operation

Another significant advantage is the maintenance-free operation of these bearings. Unlike traditional bearings that require periodic lubrication to function optimally, self-lubricating copper alloy bearings provide continuous lubrication through their embedded self-lubricating properties. This not only saves time and labor costs but also ensures the bearing remains efficient over long periods without any additional maintenance.

- Continuous lubrication, even in high-load situations

- Reduced maintenance costs and labor

- Increased uptime due to the absence of frequent maintenance schedules

Energy Efficiency and Cost-Effectiveness

Self-lubricating copper alloy bearings contribute to energy efficiency by reducing friction. This leads to smoother operation of the machinery, less energy consumption, and improved overall performance. Additionally, their durability means fewer replacements and maintenance, resulting in long-term cost savings for industries.

- Lower energy consumption due to reduced friction

- Cost savings from fewer replacements and maintenance efforts

- Improved operational efficiency

Applications of Self-Lubricating Copper Alloy Bearings

High-Temperature Environments

Self-lubricating copper alloy bearings are especially useful in high-temperature applications. Copper alloys have excellent thermal conductivity, and when combined with self-lubricating materials, they perform efficiently in extreme heat conditions. These bearings can operate in environments where traditional bearings might fail due to lubrication breakdown or material degradation.

- High-performance in industrial furnaces

- Used in engines and high-temperature motors

- Optimal for metalworking and foundries

Heavy-Duty and High-Load Applications

In applications involving heavy machinery or high-load scenarios, such as construction equipment or mining operations, self-lubricating copper alloy bearings provide excellent performance. Their ability to bear heavy loads while maintaining low friction makes them ideal for demanding environments.

- Ideal for heavy-duty industrial machinery

- Used in automotive and aerospace applications

- Can handle high loads without premature failure

How Self-Lubricating Copper Alloy Bearings Perform in Real-World Scenarios

Case Study: Improved Performance in Harsh Conditions

In real-world applications, self-lubricating copper alloy bearings have demonstrated superior performance in challenging environments. For instance, in the automotive industry, they have been used in high-performance engines to withstand the extreme conditions of temperature and load without requiring frequent maintenance.

Comparison with Traditional Bearings

When comparing self-lubricating copper alloy bearings to traditional bearings, the difference in performance is clear. Traditional bearings often require regular lubrication and maintenance, while copper alloy bearings provide continuous lubrication. The table below summarizes the key differences:

| Feature | Self-Lubricating Copper Alloy Bearings | Traditional Bearings |

| Lubrication | Self-lubricating | Requires regular lubrication |

| Maintenance | Minimal maintenance | Frequent maintenance |

| Durability | High durability | Lower durability |

FAQ

What are the main benefits of using self-lubricating copper alloy bearings?

The key benefits of self-lubricating copper alloy bearings include reduced friction, lower maintenance costs, longer lifespan, and excellent performance in high-temperature and heavy-load applications. These bearings also help improve energy efficiency by reducing energy consumption during operation.

Can self-lubricating copper alloy bearings be used in high-temperature environments?

Yes, self-lubricating copper alloy bearings are ideal for high-temperature environments. The copper alloy material provides excellent thermal conductivity, and the self-lubricating properties ensure that the bearing operates smoothly even in extreme heat conditions.

How do self-lubricating copper alloy bearings compare to traditional bearings in terms of cost-effectiveness?

Self-lubricating copper alloy bearings are highly cost-effective in the long term. Although they may have a higher initial cost, they significantly reduce maintenance and replacement costs. Their longer lifespan and energy-efficient operation make them a smart investment for industries with heavy machinery.