-

JDB Solid-lubricating Bearing JDB650 Self-Lubricating Brass Bushing Oilless Bearings

JDB Solid-lubricating Bearing JDB650 Self-Lubricating Brass Bushing Oilless Bearings -

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing -

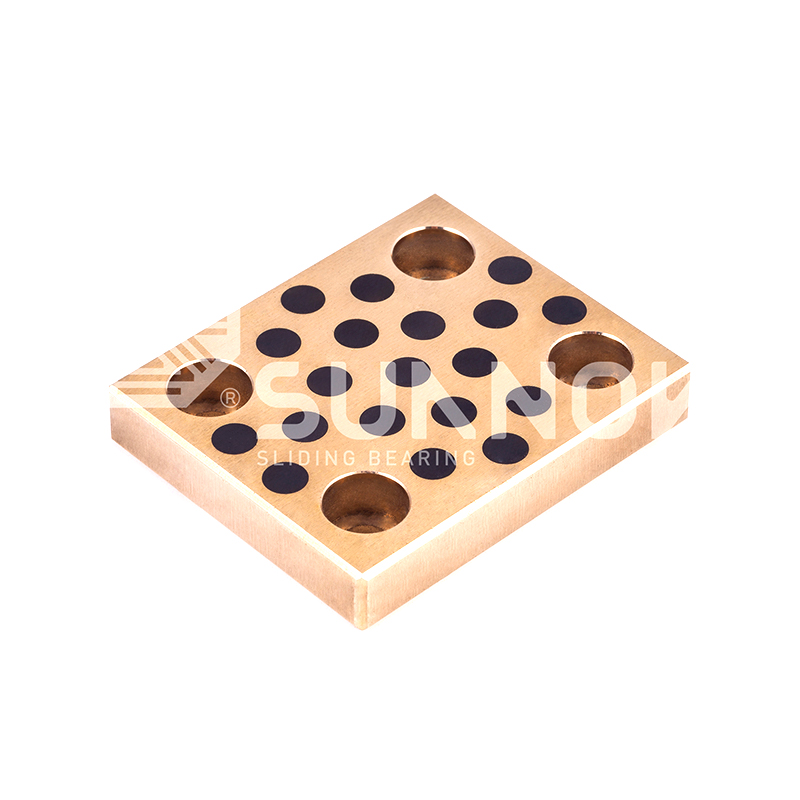

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate -

Oil-retaining Bimetallic Bearing Self-Lubricating 200# P20 Oil-Retaining Steel Bearing Plate - Low Friction Wear-Resistant

Oil-retaining Bimetallic Bearing Self-Lubricating 200# P20 Oil-Retaining Steel Bearing Plate - Low Friction Wear-Resistant -

-

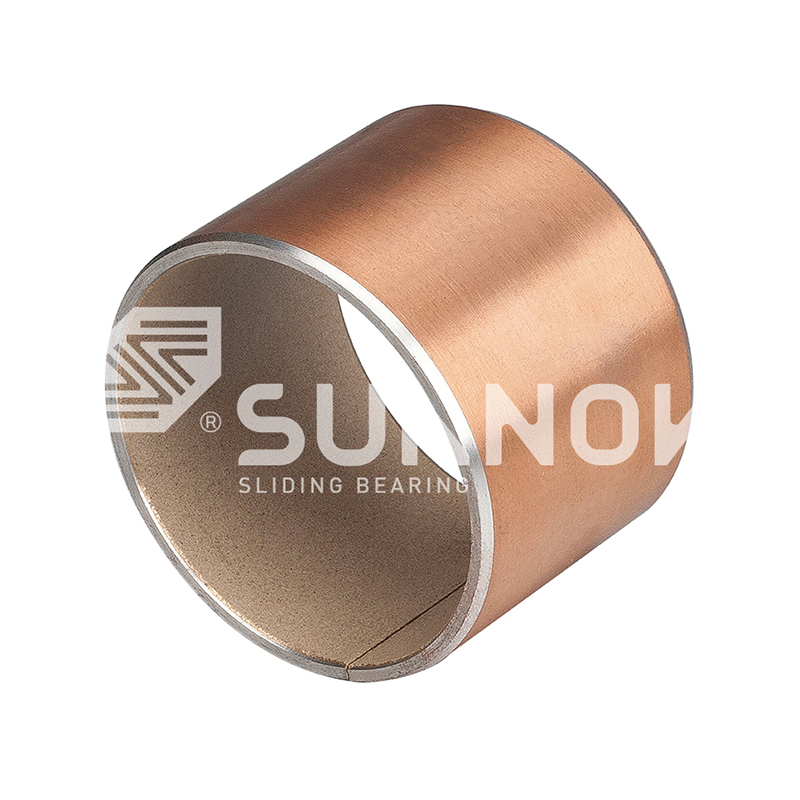

SF-1 Oilless Bearing Maintenance-Free SF-1W Wall Wrapped Lead-Free Bronze Bearing Oilless Bearing Bush

SF-1 Oilless Bearing Maintenance-Free SF-1W Wall Wrapped Lead-Free Bronze Bearing Oilless Bearing Bush -

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery

How to Optimize the Performance of Solid-Lubricating Bronze Bearings

Industry News-- 1 I. Introduction

- 2 II. Understanding Solid Lubricant Embedded Bronze Bearings

- 3 III. Self-Lubricating Bronze Bushings for High-Temperature Applications

- 4 IV. Maintenance-Free Bronze Bearings for Heavy Machinery

- 5 V. Graphite-Embedded Bronze Bearings for Marine Environments

- 6 VI. High Load Capacity Solid Lubricating Bronze Bearings

- 7 VII. Parameter Comparison of Different Bearing Types

- 8 VIII. Performance Optimization Strategies

- 9 IX. Summary

I. Introduction

Solid-lubricating bronze bearings are designed to provide reliable performance without the need for external lubrication. By embedding solid lubricants such as graphite or PTFE into a bronze matrix, these bearings achieve self-lubrication during operation. This not only reduces friction but also significantly lowers wear and maintenance requirements, making them highly suitable for demanding industrial applications. Optimizing the performance of these bearings ensures longer service life, improved efficiency, and fewer unscheduled downtimes.

Industries ranging from heavy machinery to marine environments increasingly rely on solid-lubricating bronze bearings because of their resilience under extreme temperatures, high loads, and corrosive conditions. By understanding their material properties, design features, and operational best practices, engineers can select the most suitable bearing type for their applications. Performance optimization requires a holistic approach that considers materials, design, and application-specific requirements.

II. Understanding Solid Lubricant Embedded Bronze Bearings

Solid lubricant embedded bronze bearings combine a strong bronze alloy with integrated solid lubricants to create a self-lubricating surface. The embedded lubricant gradually releases during operation, forming a low-friction layer between the bearing and the shaft, which reduces wear and extends service life. This design eliminates the need for continuous external lubrication, which is particularly advantageous in environments where conventional lubrication is impractical or impossible.

Benefits Over Traditional Bearings

- Reduced maintenance requirements, eliminating frequent lubrication schedules

- Enhanced durability in harsh environments including high temperatures and heavy loads

- Consistent performance over long periods due to continuous self-lubrication

- Lower operational costs by minimizing downtime associated with manual lubrication

Compared to traditional bronze or steel bearings, solid lubricant embedded bronze bearings offer superior reliability in environments where oil or grease maintenance is difficult. They are particularly beneficial in closed systems, vacuum applications, or heavy-duty industrial machinery where conventional lubrication can fail or contaminate the system.

III. Self-Lubricating Bronze Bushings for High-Temperature Applications

High-temperature applications, such as in furnaces, engines, or industrial heating systems, challenge traditional bearings because conventional lubricants degrade at elevated temperatures. Self-lubricating bronze bushings for high-temperature applications use solid lubricants that maintain their properties even at extreme heat, allowing bearings to function reliably without external lubrication. This enhances equipment uptime and prevents premature bearing failure due to lubricant breakdown.

Advantages

- Stable performance at elevated temperatures where oil or grease would evaporate or oxidize

- Prevention of bearing seizure due to lubricant degradation

- Extended service life and reduced replacement frequency

- Improved operational efficiency under continuous high-temperature stress

For example, in comparison to conventional bronze bearings with oil lubrication, self-lubricating bronze bushings for high-temperature applications maintain consistent friction levels at temperatures above 300°C. This makes them ideal for furnace rollers, high-speed industrial motors, and other thermal-intensive machinery.

IV. Maintenance-Free Bronze Bearings for Heavy Machinery

Heavy machinery such as excavators, presses, and industrial conveyors often operate under high loads and continuous use, making lubrication maintenance a challenge. Maintenance-free bronze bearings for heavy machinery are engineered to eliminate regular lubrication while providing reliable wear resistance. This is crucial for reducing downtime and minimizing maintenance costs in industrial operations.

Role in Reducing Downtime

- Elimination of lubrication-related failures, which are common in conventional bearings

- Increased reliability and operational uptime due to self-lubricating design

- Reduced labor and operational costs associated with manual maintenance

- Improved safety, as workers are less exposed to hazardous environments during maintenance

When compared with standard bronze bushings that require periodic oiling or greasing, maintenance-free bronze bearings for heavy machinery offer superior lifecycle performance. Their embedded solid lubricants provide continuous friction reduction even under fluctuating load conditions, making them ideal for equipment that cannot tolerate frequent downtime.

V. Graphite-Embedded Bronze Bearings for Marine Environments

Marine environments expose bearings to saltwater corrosion, high humidity, and continuous motion, which can drastically reduce the life of conventional bearings. Graphite-embedded bronze bearings for marine environments integrate corrosion-resistant bronze with solid graphite lubricants. This combination ensures self-lubrication while resisting the aggressive effects of saltwater and reducing maintenance needs.

Benefits

- Enhanced resistance to corrosion from saltwater and moisture

- Ability to operate efficiently in submerged or high-humidity conditions

- Longer service life compared to traditional lubricated marine bearings

- Reduced need for periodic inspections and re-lubrication

For comparison, traditional oil-lubricated bronze bearings in marine settings may corrode within months, whereas graphite-embedded bronze bearings for marine environments can operate for years without external lubrication, maintaining smooth operation and reducing operational costs.

VI. High Load Capacity Solid Lubricating Bronze Bearings

Applications that involve heavy loads require bearings with sufficient strength to handle extreme pressures without deformation or failure. High load capacity solid lubricating bronze bearings are specifically designed to meet these demands, combining robust bronze alloys with embedded lubricants to reduce friction and wear under high-pressure conditions. This makes them suitable for presses, mining equipment, and industrial machinery with continuous high-load operations.

Features

- High load-bearing capacity suitable for industrial and heavy machinery

- Enhanced wear resistance under repeated stress

- Compatibility with self-lubricating materials for minimal maintenance

- Improved operational efficiency even under dynamic load variations

In comparison to standard bronze bearings, high load capacity solid lubricating bronze bearings can tolerate up to 30% more pressure before exhibiting signs of wear, making them a reliable choice for heavy-duty industrial applications where downtime and repair costs are critical concerns.

VII. Parameter Comparison of Different Bearing Types

To further optimize performance, it is helpful to compare key parameters of different solid-lubricating bronze bearings types. The table below summarizes operating temperature range, load capacity, maintenance requirement, and environmental suitability for each bearing type:

| Bearing Type | Operating Temperature (°C) | Max Load (MPa) | Maintenance Requirement | Ideal Environment |

|---|---|---|---|---|

| Solid lubricant embedded bronze bearings | -50 to 250 | 50 | Minimal | General industrial |

| Self-lubricating bronze bushings for high-temperature applications | -50 to 350 | 45 | Low | High-temperature machinery |

| Maintenance-free bronze bearings for heavy machinery | -40 to 200 | 70 | None | Heavy-load equipment |

| Graphite-embedded bronze bearings for marine environments | -30 to 180 | 40 | None | Marine, high-humidity |

| High load capacity solid lubricating bronze bearings | -50 to 220 | 90 | Minimal | Heavy-duty industrial |

VIII. Performance Optimization Strategies

Material Selection

Choosing the appropriate bronze alloy and compatible solid lubricant is fundamental. Alloys like C93200 or C83600 provide excellent wear resistance, while graphite, PTFE, or molybdenum disulfide ensure smooth self-lubrication. Material selection should consider operating temperature, load, and environmental exposure to maximize bearing life.

Design Considerations

Design features such as lubrication grooves, optimized clearance, and surface finishing play a crucial role in enhancing performance. Grooves distribute the lubricant evenly, while proper clearance minimizes friction without compromising load capacity. Engineers must tailor these parameters to the specific operational conditions of the machinery.

Lubrication Techniques

While solid-lubricating bronze bearings are self-lubricating, initial lubrication during installation can reduce startup friction. This is particularly important for high-load or high-speed applications. Proper installation ensures the embedded lubricant functions effectively and extends the bearing's operational life.

IX. Summary

Optimizing solid-lubricating bronze bearings requires a combination of careful material selection, intelligent design, and understanding of the operating environment. By using solid lubricant embedded bronze bearings, self-lubricating bronze bushings for high-temperature applications, maintenance-free bronze bearings for heavy machinery, graphite-embedded bronze bearings for marine environments, and high load capacity solid lubricating bronze bearings, industries can enhance reliability, reduce downtime, and lower maintenance costs across diverse applications.