-

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing

JDB Solid-lubricating Bearing GB71 NAAMS Flange Bushing Shoulder Type Standard Solid-lubricating Bearing -

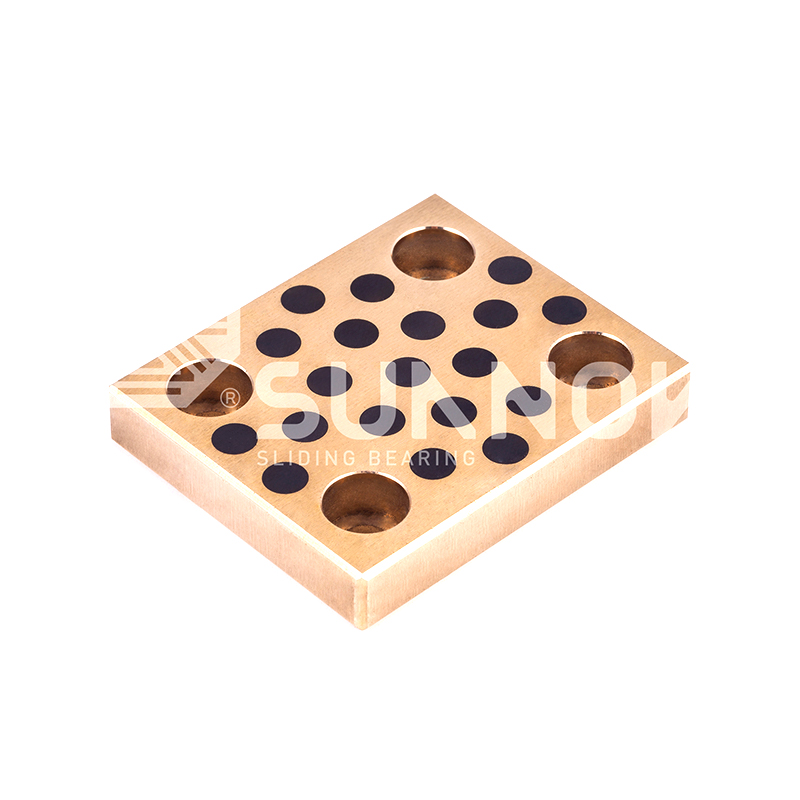

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate -

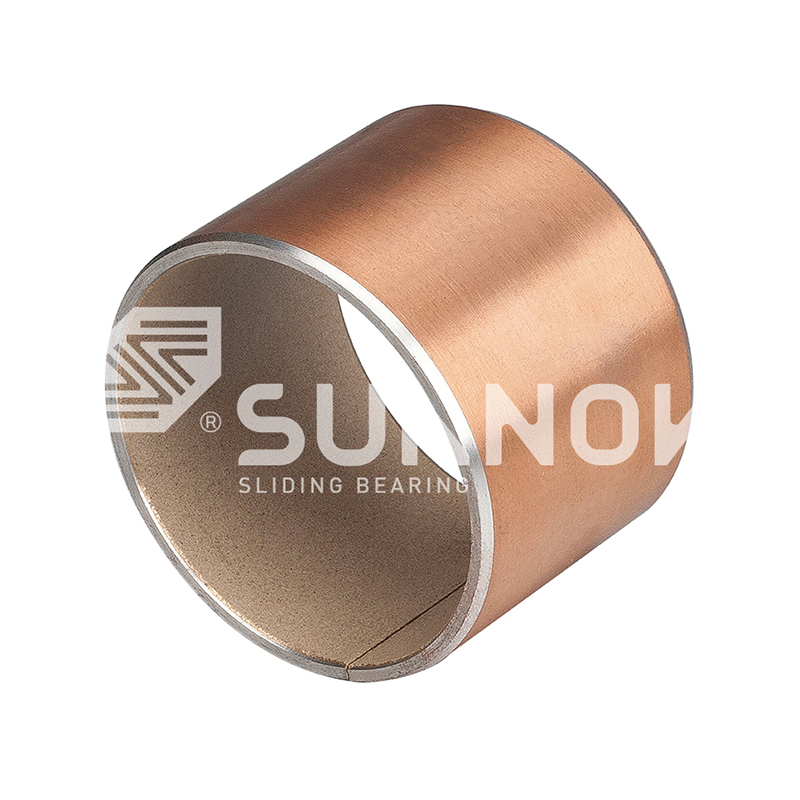

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed)

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed) -

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing -

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery -

FB090 Bronze Wrapped Bearing FB091 High-Performance Copper Wrapped Bearing & Bushing | Bronze Bush

FB090 Bronze Wrapped Bearing FB091 High-Performance Copper Wrapped Bearing & Bushing | Bronze Bush -

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

The Benefits of Maintenance-Free Solid Lubricant Bearings for Industrial Applications

Industry News-Maintenance-free solid lubricant bearings are revolutionizing industrial machinery by reducing downtime and operational costs. Unlike traditional oil or grease-lubricated bearings, these bearings use embedded solid lubricants, such as graphite, PTFE, or molybdenum disulfide, to provide long-lasting performance without the need for frequent maintenance.

JFBB Metric Self-lubricating Oilless Graphite Flanged Bearings Bushings

How Maintenance-Free Solid Lubricant Bearings Work

Solid lubricant bearings incorporate dry lubricants within their structure, which gradually release during operation to reduce friction. Common materials include:

PTFE (Teflon): Low friction, chemical resistance

Graphite: High-temperature stability, electrical conductivity

Molybdenum Disulfide (MoS2): Extreme pressure resistance

These materials eliminate the need for external lubrication systems, making them ideal for harsh environments where oil or grease may fail.

Key Advantages Over Traditional Bearings

Zero Maintenance Required

No relubrication needed, reducing labor costs and machine downtime.

Ideal for hard-to-reach or sealed applications.

Extended Service Life

Solid lubricants degrade slower than oils, leading to longer bearing life.

Example: In a steel mill, solid lubricant bearings lasted 3x longer than grease-lubricated ones.

Better Performance in Extreme Conditions

Operate reliably in high temperatures (up to 350°C for some graphite-based bearings).

Resistant to dust, water, and corrosive chemicals.

Lower Total Cost of Ownership

Reduced maintenance and longer lifespan offset higher initial costs.

Case study: A mining company cut bearing-related costs by 40% after switching.

Common Applications

Food & Beverage: No oil contamination risk, meeting hygiene standards.

Aerospace: Lightweight, reliable in vacuum and extreme temperatures.

Automotive: Used in suspension and transmission systems.

Heavy Industry: Ideal for crushers, conveyors, and high-load machinery.

Solid Lubricant vs. Traditional Bearings: A Quick Comparison

| Feature | Solid Lubricant Bearings | Oil/Grease Bearings |

|---|---|---|

| Maintenance Frequency | None | Regular relubrication required |

| Temperature Range | -200°C to +350°C | Limited by oil breakdown |

| Contamination Risk | None | Potential leaks and dust ingress |

| Lifespan | 2-3x longer | Shorter, wear-dependent |

| Initial Cost | Higher | Lower |

| Extreme Environment Performance | Excellent (vacuum, radiation, etc.) | Poor |