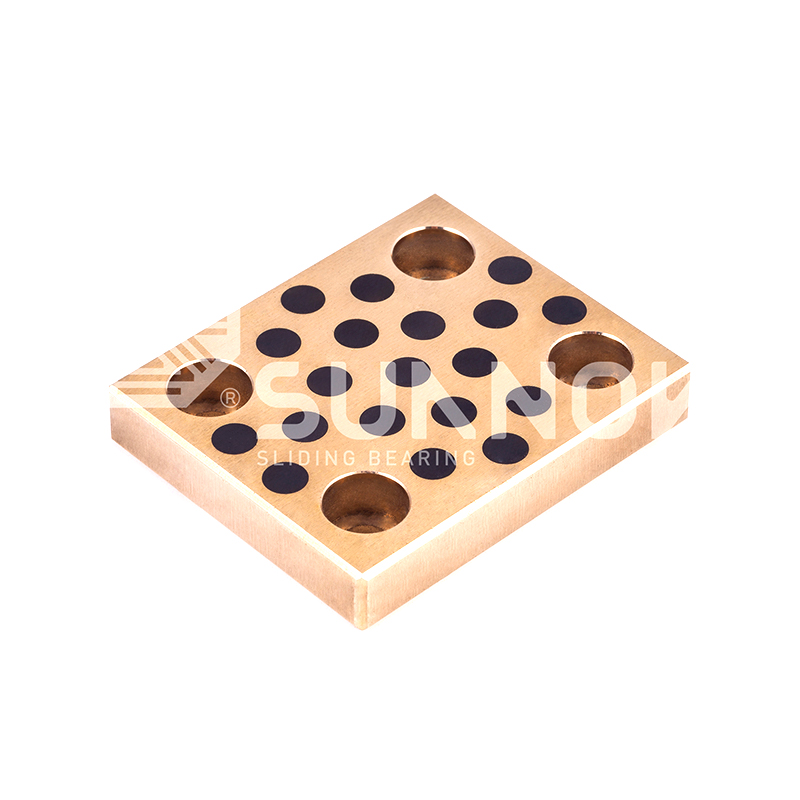

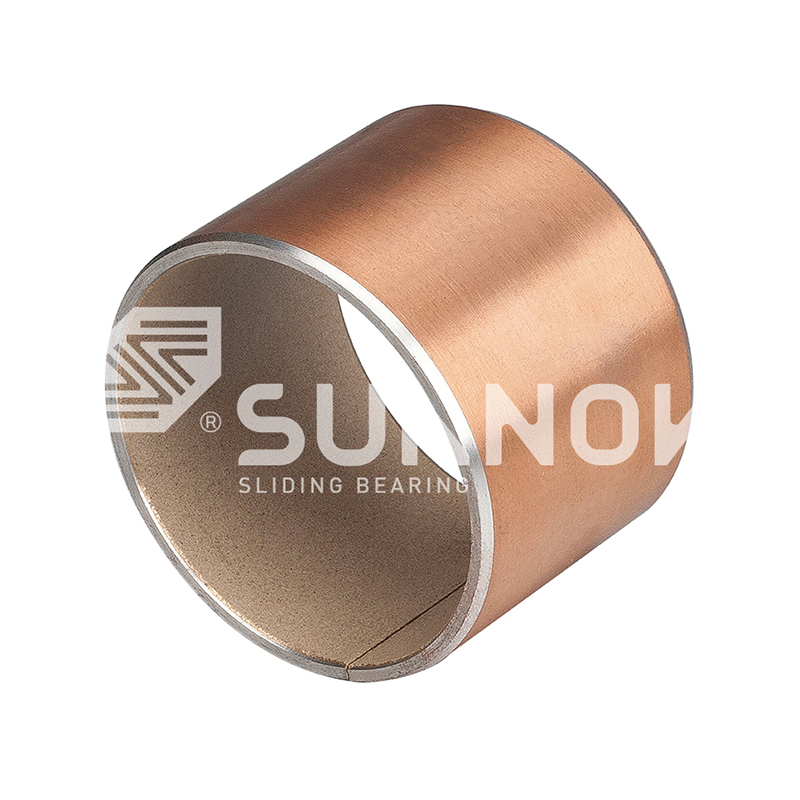

FB09G Bronze Wrapped Bearing Bushing is a high-performance, cost-effective solution for various industrial applications requiring robust lubrication and wear resistance. This type of industrial bronze bearing is engineered from a single bronze strip, cold-formed to a precise cylindrical shape. The body is wrapped and a butt joint is created, ensuring a seamless fit and superior structural integrity. The inner surface features strategically placed through holes or indentations, serving as reservoirs for grease or oil lubrication. This design principle ensures a constant and reliable lubricant supply, significantly extending service life and reducing maintenance costs. These bearings are particularly well-suited for medium to high-load applications where shock resistance and durability are critical.

Product Features and Advantages

- Self-Lubricating Design: The embedded lubrication reservoirs on the inner surface ensure a continuous supply of lubricant, reducing friction and wear even under heavy loads. This feature makes it a reliable lubrication bronze bushing for demanding operational environments.

- High Load Capacity: Manufactured from a strong, wear-resistant bronze alloy, the FB09G bearing offers excellent load-bearing capabilities and resistance to impact. It is a preferred choice for heavy machinery and equipment.

- Extended Service Life: The combination of robust material and effective lubrication channels significantly prolongs the bearing's operational life, reducing the frequency of replacement and associated downtime. This is a key benefit for any industrial operation seeking a durable wrapped bronze bearing.

- Reduced Maintenance: The self-lubricating feature minimizes the need for frequent manual lubrication, simplifying maintenance procedures and lowering long-term operational costs.

Application Fields

The FB09G industrial bronze wrapped bearing is widely used across various sectors due to its robust performance and durability. This versatile bronze bearing bushing is suitable for applications that require reliable motion and load support, including:

- Agricultural Machinery: Used in tractors, combines, and plows where bearings are subjected to heavy loads and contaminated environments.

- Construction Equipment: Essential for excavators, cranes, and bulldozers, where shock loads and durability are critical factors.

- Automotive Industry: Applied in vehicle chassis, steering systems, and hydraulic cylinders.

- General Industrial Machinery: Ideal for conveyor systems, gearboxes, and pumps.

Frequently Asked Procurement Questions

1. How does the FB09G Bronze Wrapped Bearing compare to a Sintered Bronze Bearing for my hydraulic cylinder application?

The FB09G bronze wrapped bearing is engineered from a solid, cold-formed bronze strip (CuSn8P), providing superior strength and load-bearing capacity (up to 250 N/mm²) compared to a porous sintered bronze bearing. Sintered bearings rely on an oil-impregnated structure, which can be insufficient for high-load or high-impact conditions, leading to premature wear. The FB09G's robust construction and ability to be re-lubricated with grease make it a more reliable choice for demanding applications like hydraulic cylinders, where durability and resistance to shock loads are paramount. For specific recommendations, our technical team can analyze your operational requirements and provide a tailored solution.

2. We are experiencing premature bearing failure due to dust and abrasive particles. Will your bronze bearing solve this issue?

The FB09G bronze bearing, with its solid structure and designed lubrication holes, can better withstand environments with contaminants than many other bearing types. The grease or oil reservoirs can act as a barrier against small particles, while the hardened bronze alloy provides strong resistance to abrasive wear. However, for severe environments, a comprehensive solution typically involves a combination of the correct bearing material and an effective sealing system to prevent ingress of contaminants. We recommend a free consultation with our application engineers to determine the best sealing and lubrication strategy to extend the service life of your industrial bronze bushing in such a challenging environment.