-

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings -

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing -

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing -

-

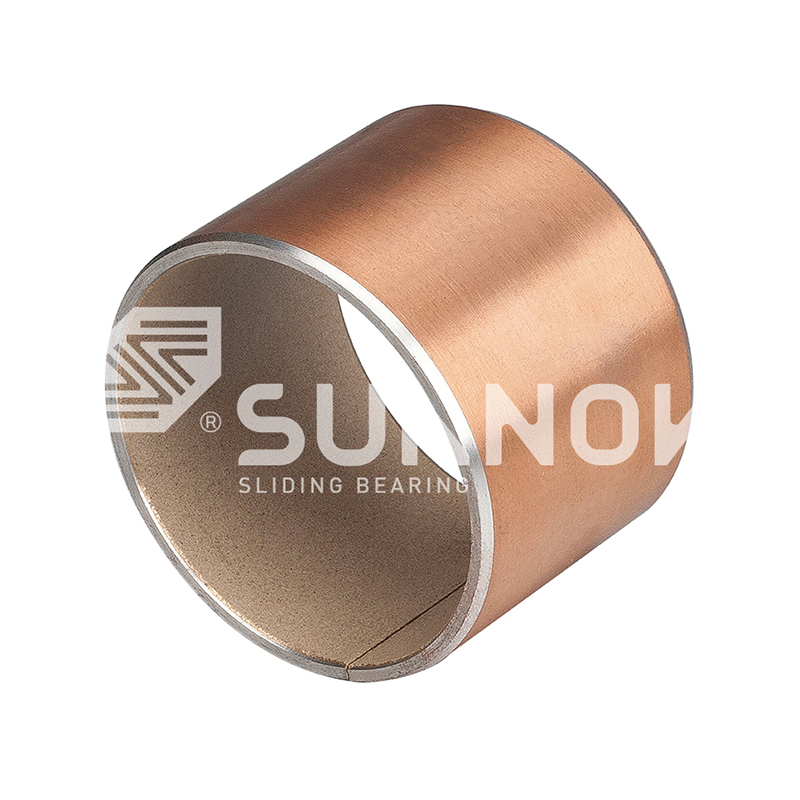

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

-

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications -

FB090 Bronze Wrapped Bearing FB090 Bronze Wrapped Bearing | Self-Lubricating Bushing & Sleeve

FB090 Bronze Wrapped Bearing FB090 Bronze Wrapped Bearing | Self-Lubricating Bushing & Sleeve

Understanding Self‑Lubricating Bronze Bushings: A Comprehensive Guide

Industry News-- 1 What Are Self‑Lubricating Bronze Bushings?

- 2 Key Types & Mechanisms of Self‑Lubrication

- 3 Advantages of Self‑Lubricating Bronze Bushings in Industrial Applications

- 4 Selecting the Right Self‑Lubricating Bronze Bushing – What to Consider

- 5 Comparison Table: Self‑Lubricating vs Standard Bronze Bushings

- 6 Practical Application Examples & Industry Use Cases

- 7 FAQs

In modern machinery design, selecting the right bearing solution is critical for performance, reliability and maintenance cost control. Among these options, self lubricating bronze bushings offer a compelling combination of durability, low maintenance and high load‑capacity service. This guide explores the working principles, advantages, and selection criteria for these components, with insights from experience at Zhejiang Shuangnuo Bearing Technology Co., Ltd., a manufacturer specialising in self‑lubricating copper‑alloy bearing products.

Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing

What Are Self‑Lubricating Bronze Bushings?

Definition and core concept

- A self lubricating bronze bushing is a bearing component made from a bronze or copper‑alloy matrix that incorporates its own lubrication mechanism — eliminating or significantly reducing the need for external grease or oil.

- Unlike standard bushings that rely on scheduled lubrication, self‑lubricating types embed lubrication capability in the material structure or via inserted solid lubricants.

How they differ from standard bronze bushings

- Standard bronze bushings typically require regular greasing or oil lubrication during operation.

- The difference mainly lies in internal lubrication structure: porous & oil‑impregnated bronze or bronze with graphite plugs vs plain bronze alloy.

Key Types & Mechanisms of Self‑Lubrication

Oil‑impregnated bronze bushings (linked to "self lubricating bronze bushings oil‑impregnated bronze bushings advantages")

- This type uses porous bronze material produced by powdered metallurgy, then impregnated with lubricating oil.

- Under operation, heat or pressure causes the oil to migrate to the sliding interface, providing continuous lubrication.

- Best suited for moderate‑load, medium‑speed applications where automatic lubrication is beneficial.

Graphite‑plugged or embedded solid lubricant bronze bushings (linked to "self lubricating bronze bushings embedded graphite plugs")

- In this design, a strong bronze alloy (often cast) is machined with small holes which are then filled with solid lubricants such as graphite or other dry films.

- As the bearing operates, the solid lubricant builds a friction‑reducing film on the shaft or mating surface — ideal for heavy‑load, low‑speed or high‑temperature environments.

Advantages of Self‑Lubricating Bronze Bushings in Industrial Applications

Maintenance‑free operation ("self lubricating bronze bushings maintenance‑free bearings")

- With lubrication built in, these bushings reduce or eliminate the need for scheduled greasing.

- Reduced maintenance means lower labour costs and less downtime.

Heavy‑equipment suitability ("self lubricating bronze bushings for heavy equipment")

- Many heavy‑equipment applications involve difficult access for lubrication or long periods of continuous operation. Self‑lubricating bronze bushings are well suited for those scenarios.

- Because of good load‑carrying capacity and wear resistance of bronze alloys, they are reliable in heavy‑duty environments.

Long service life, load capacity, and corrosion resistance

- Bronze alloys are known for high strength, good wear resistance and ability to operate in corrosive environments.

- Combined with self‑lubricating design, the service life is extended compared to standard plain bearings that suffer lubricant starvation or frequent relubrication.

Selecting the Right Self‑Lubricating Bronze Bushing – What to Consider

Material and alloy choice (casting, copper‑alloy, manufacturer selection) ("self lubricating bronze bushings manufacturer cast copper alloy bushings")

- The base alloy (e.g., tin bronze, aluminum bronze, brass) must match performance requirements: load, speed, temperature, corrosion.

- Manufacturing route matters: casting, continuous casting, centrifugal casting, or sintering. For example, our company, Zhejiang Shuangnuo Bearing Technology Co., Ltd., uses independent casting production of raw materials to ensure product quality from the source.

- Embedded lubrication techniques or impregnation processes must be verified for consistency and long‑term performance.

Operating conditions: load, speed, temperature, environment

- Ensure the bushing's PV (pressure × velocity) rating aligns with your application.

- Consider temperature extremes, exposure to contaminants (dust, corrosion), and access for maintenance.

- Where external lubrication is hard or impossible (e.g., food processing, mining), self‑lubricating options shine.

Quality assurance: raw material control, testing, manufacturing process

- Reliable manufacturers will monitor the casting and machining process and provide material composition and mechanical‑property test reports.

- At Zhejiang Shuangnuo Bearing Technology Co., Ltd., the entire process—from raw material to finished product—is monitored: spectrometer tests are performed three times (before, in and after furnace) to confirm composition; national testing agencies are engaged regularly for mechanical testing; over 80 sets of advanced CNC machines are used to process components, shortening production cycle and improving precision.

- Such rigorous control ensures durability, performance and repeatability—critical for industrial‑grade self‑lubricating bushings.

Comparison Table: Self‑Lubricating vs Standard Bronze Bushings

| Feature | Standard Bronze Bushing | Self‑Lubricating Bronze Bushing |

| Lubrication source | External grease or oil | Internal lubrication built in (oil‑impregnated or solid plugs) |

| Maintenance frequency | High – regular relubrication required | Low – minimal to no external lubrication |

| Suitability for inaccessible areas | Limited – hard to service areas problematic | High – ideal for hard‑to‑reach or continuous operation |

| Load/temperature range | Good for many applications | Better for heavy‑load, high‑temperature or contaminated environments |

| Total lifecycle cost | Higher due to maintenance downtime | Lower due to reduced maintenance and longer service intervals |

Practical Application Examples & Industry Use Cases

Construction & mining equipment

- Large machines operating in dusty or abrasive environments benefit from self‑lubricating bushings because external lubrication may be difficult and contamination high.

- The heavy load and intermittent movement of such equipment align well with the robust load capacity of bronze alloys plus self‑lubricating functionality.

Marine, chemical, food‑processing and hard‑to‑reach maintenance environments

- In marine or chemical plants, corrosion and fluid contamination present challenges; bronze alloys plus embedded lubrication help mitigate these risks.

- In food‑processing or clean‑room environments, external grease may be prohibited; self‑lubricating bronze bushings offer a clean, maintenance‑reduced alternative.

FAQs

- How long do self‑lubricating bronze bushings last compared to standard bushings?

The lifespan depends on load and conditions, but because self‑lubricating bushings maintain a consistent lubrication film without external intervention, they typically last significantly longer than standard bushings that suffer from lubricant depletion or contamination. - Can I retrofit standard bronze bushings with self‑lubricating versions?

Yes — in many cases, you can replace standard bronze bushings with self‑lubricating types, provided the dimensions, shaft material, load, speed, and environment match. It's important to verify compatibility and load ratings with the manufacturer. - Are oil‑impregnated and graphite‑plugged self‑lubricating bushings interchangeable?

They are not directly interchangeable for all applications because each uses a different lubrication mechanism and suits different service conditions (speed, load, temperature, environment). Selection must be made based on the specific demands of the application.

What maintenance is still required for self‑lubricating bronze bushings?

- While these bushings reduce or eliminate external lubrication, you should still monitor bearing condition, check for misalignment or abnormal wear, and ensure the environment is not excessively abrasive or contaminated.

- How does your company ensure quality in self‑lubricating bronze bushings?

At Zhejiang Shuangnuo Bearing Technology Co., Ltd., we conduct independent casting of raw materials, monitor the casting and machining process thoroughly, test material composition before, during and after furnace using spectrometers, engage national testing agencies for mechanical properties, and operate over 80 advanced CNC machine tools to ensure precision and consistent production quality.