-

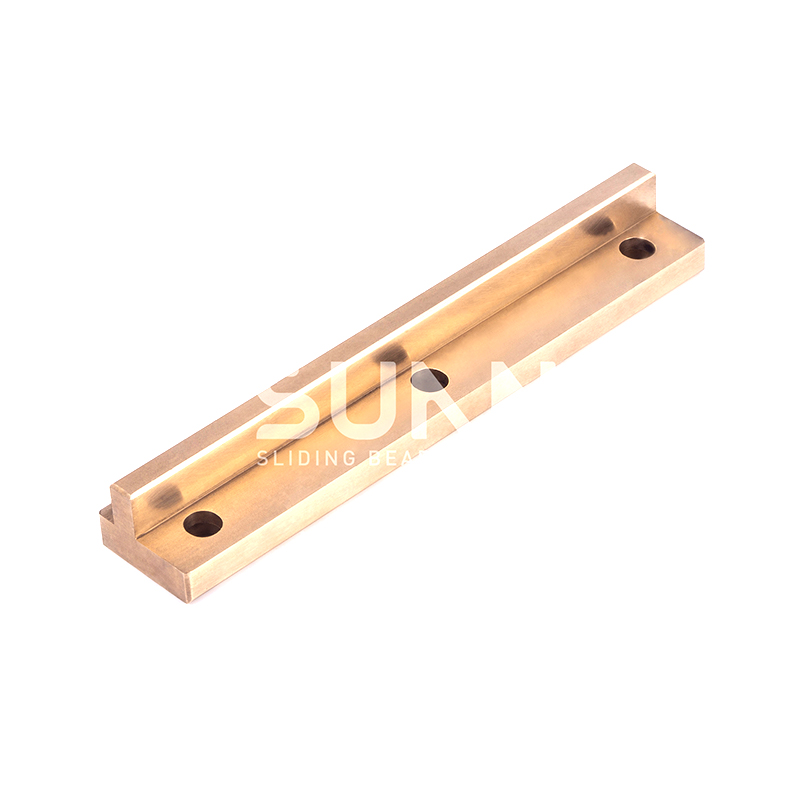

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing -

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate -

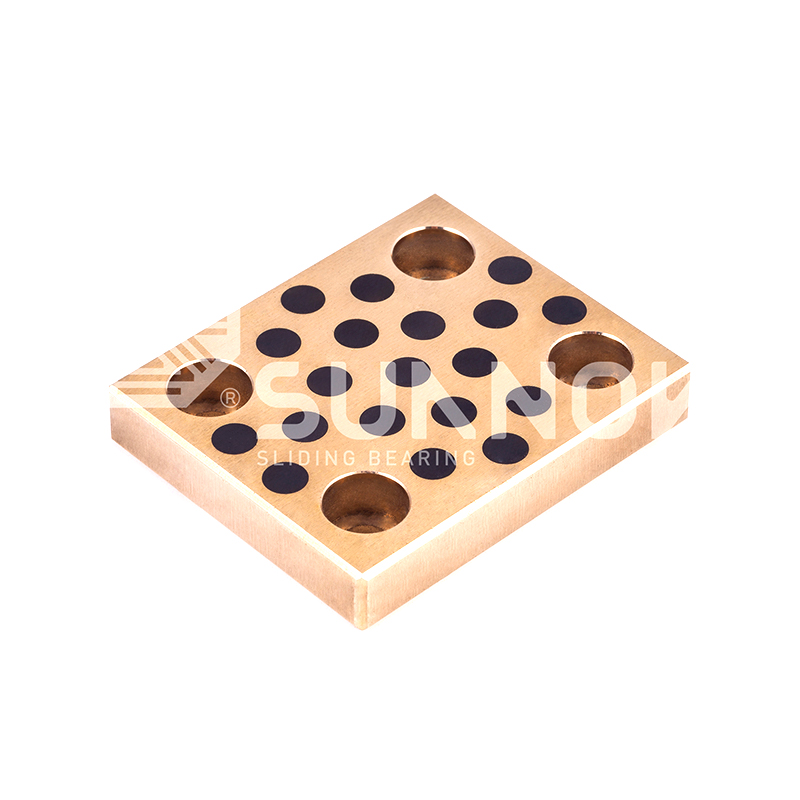

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components -

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed)

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed) -

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush -

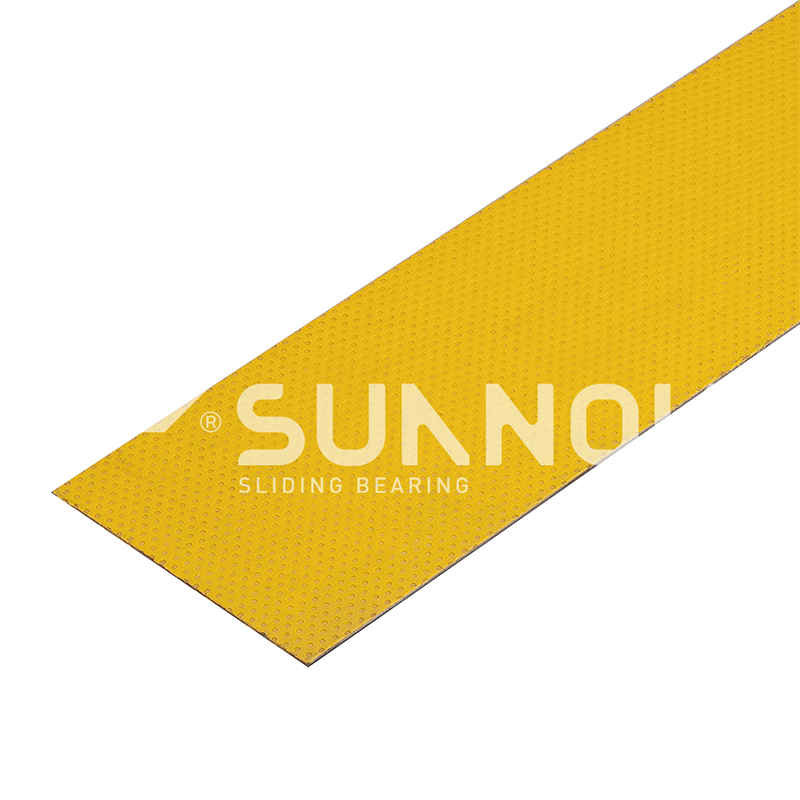

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE -

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications -

Why Solid-Lubricating Bronze Bearings Are the Future of Low-Maintenance Machinery

Industry News-Understanding Solid-Lubricating Bronze Bearings

Solid-lubricating bronze bearings have become a game-changer in industrial applications where traditional lubrication fails. These bearings incorporate solid lubricants like graphite or PTFE within the bronze matrix, providing continuous lubrication without external oil or grease. The best solid-lubricating bronze bearing materials combine high load capacity with excellent wear resistance, making them ideal for harsh environments.

JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings

1.1 How Solid Lubrication Works in Bronze Bearings

Unlike conventional bearings requiring fluid lubrication, solid-lubricated versions work through embedded lubricants that gradually release during operation. This mechanism offers several advantages:

- No lubrication starvation during startup

- Consistent performance across temperature extremes

- Reduced contamination risk in clean environments

Key Applications of Self-Lubricating Bronze Bushings

The applications of self-lubricating bronze bushings span multiple industries, particularly where maintenance access is challenging. Common use cases include:

2.1 Heavy Machinery and Construction Equipment

These bearings excel in excavators, cranes, and mining equipment where dust and debris would compromise traditional bearings. Their ability to function without external lubrication makes them perfect for:

| Application | Benefit |

|---|---|

| Hydraulic cylinder pivots | Eliminates grease fittings in hard-to-reach areas |

| Track rollers | Withstands impact loads and contamination |

Comparing Bronze Bearings With Other Materials

When evaluating solid-lubricated bronze vs oil-impregnated bearings, several factors come into play:

3.1 Performance Under Extreme Conditions

Bronze bearings with solid lubricants maintain functionality where oil-lubricated types would fail:

| Condition | Bronze with Solid Lubricant | Oil-Impregnated |

|---|---|---|

| High temperatures (200°C+) | Stable performance | Oil breakdown |

| Vacuum environments | No outgassing | Lubricant loss |

Maintenance Tips for Long-Lasting Performance

While maintenance-free bronze bearings require minimal attention, proper installation ensures maximum service life:

4.1 Proper Installation Techniques

Correct handling prevents premature wear:

- Always use arbor presses instead of hammers

- Ensure proper clearance for thermal expansion

- Clean housing surfaces before installation

Selecting the Right Bearing for High-Load Applications

For high-load solid-lubricating bronze bushings, consider these critical factors:

5.1 Load Capacity Calculations

Understanding PV (Pressure-Velocity) limits prevents premature failure:

| Bearing Type | Max PV (psi x fpm) |

|---|---|

| Standard Bronze | 50,000 |

| Graphite-Embedded | 75,000 |

5.2 Temperature Considerations

Different lubricants perform optimally at specific ranges:

- Graphite: -200°C to 500°C

- PTFE: -100°C to 260°C