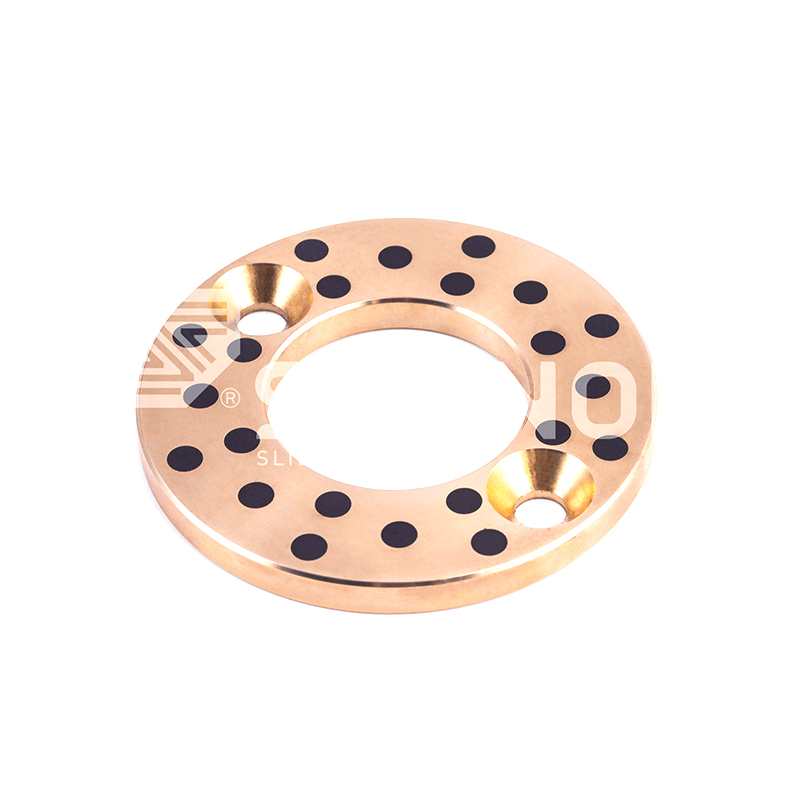

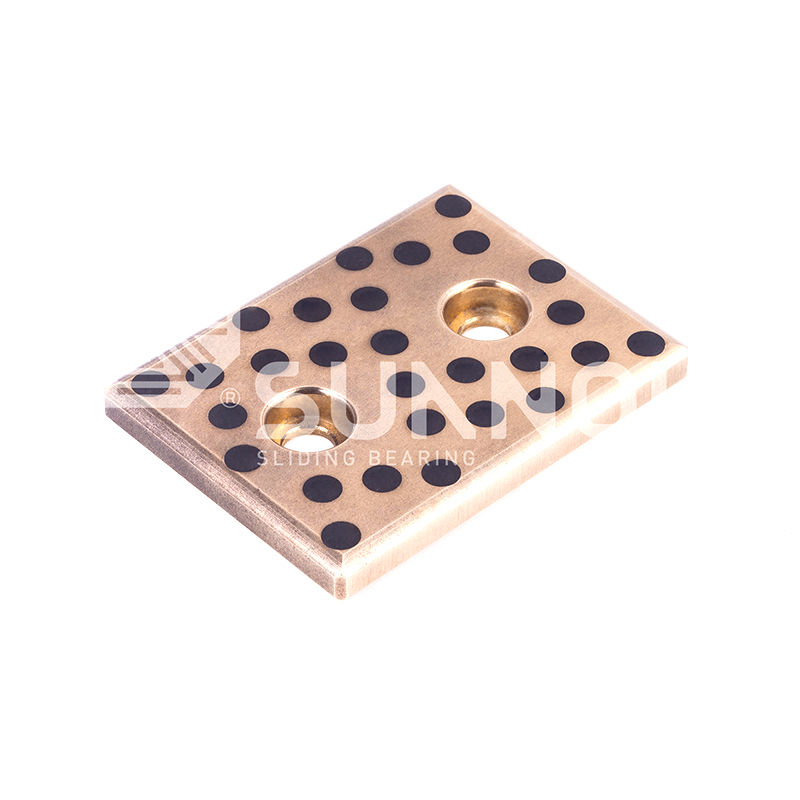

Self-Lubricating SF-1T Metal Gear Pump Bearing Bronze Bushings

High-Performance, Maintenance-Free Solution for Gear Pumps

The SF-1T Bronze Bushings are engineered for heavy-duty gear pumps, offering superior self-lubrication, wear resistance, and extended service life. Ideal for hydraulic systems, industrial machinery, and high-load applications where reliability is critical.

Product Features

Self-lubricating performance

SF-1T self-lubricating material is used, no additional lubricating oil or grease is required, which greatly reduces maintenance costs and reduces friction and wear during equipment operation.

High-strength design

Made of high-quality bronze matrix, it has excellent load-bearing capacity and is suitable for gear pump operation under high-load conditions.

Wear resistance and corrosion resistance

The use of high-quality materials and precision technology ensures long-term stable operation of the product under high temperature, high pressure and chemical environment.

Environmental protection and energy saving

The self-lubricating characteristics reduce the use of lubricants, are environmentally friendly, and optimize the energy consumption performance of the equipment.

Customized service

Provide a variety of specifications and sizes to meet the needs of different industries and equipment, and can be customized according to customer drawings.

Why choose us?

20+ Years of expertise in bronze bushing manufacturing.

ISO 9001-certified production with strict QC checks.

24/7 Technical Support – Our engineers help you select the right bushing.

Fast Global Shipping – Please confirm the specific time with us