-

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing -

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing -

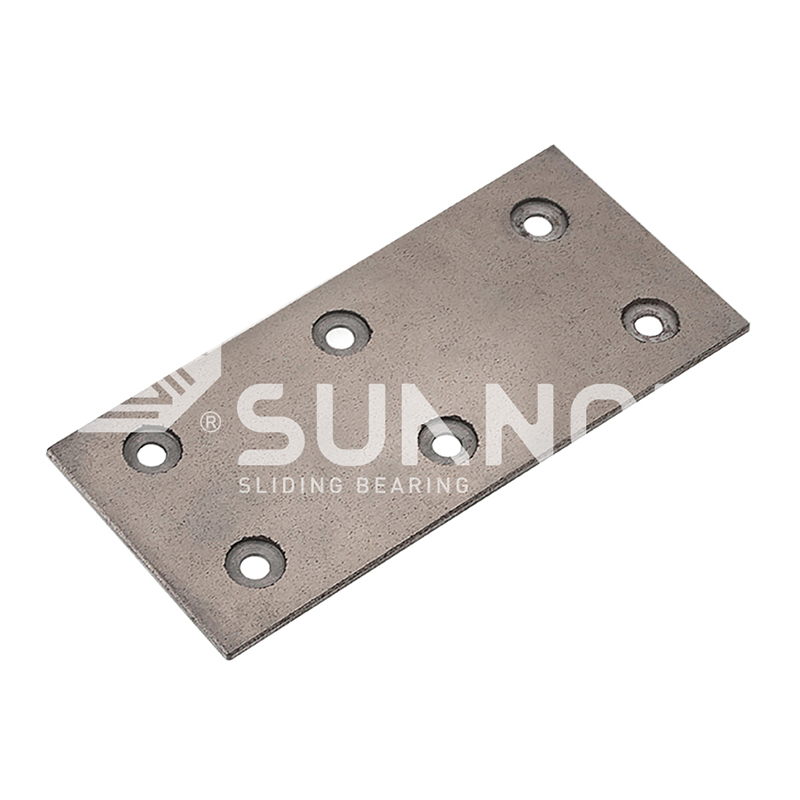

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface -

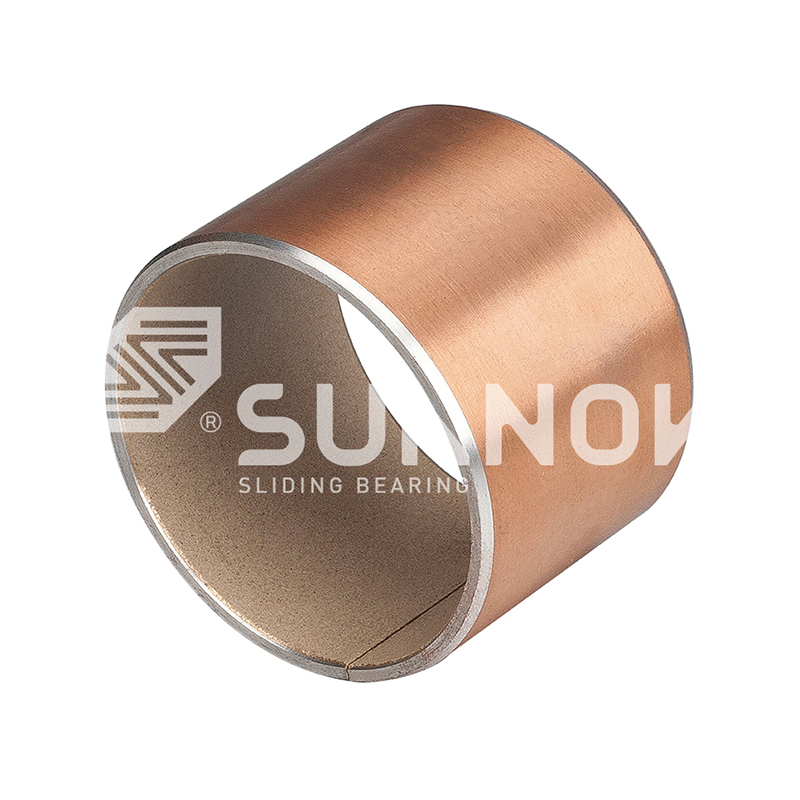

SF-1 Oilless Bearing Maintenance-Free SF-1W Wall Wrapped Lead-Free Bronze Bearing Oilless Bearing Bush

SF-1 Oilless Bearing Maintenance-Free SF-1W Wall Wrapped Lead-Free Bronze Bearing Oilless Bearing Bush -

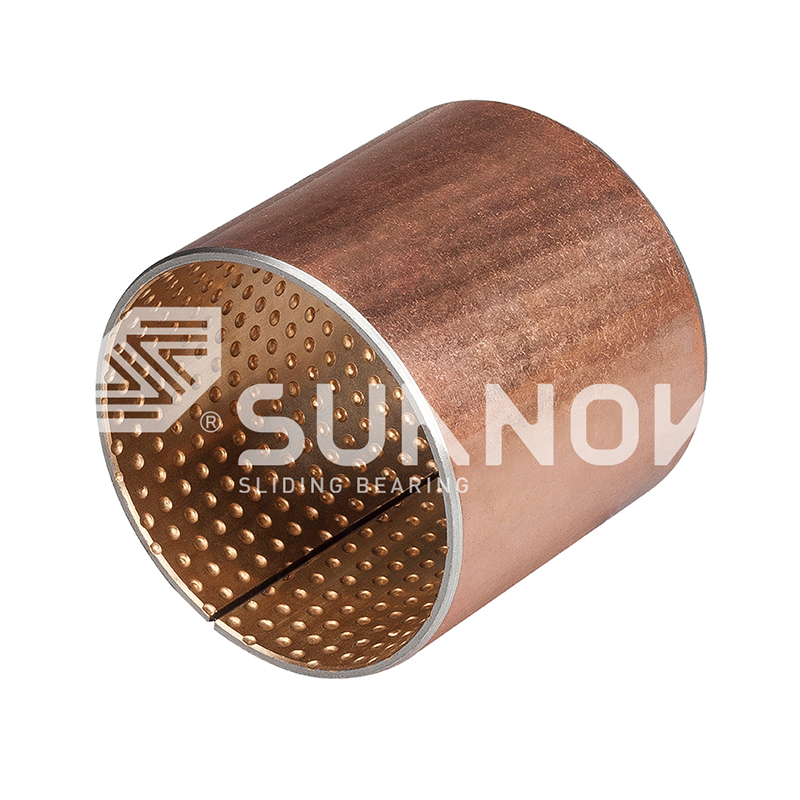

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

-

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip -

FB090 Bronze Wrapped Bushing Bearing: A Comprehensive Technical Guide

Industry News-- 1 1. Key Dimensions of the FB090 Bronze Wrapped Bushing Bearing

- 2 2. Advantages and Applications of the FB090 Self-Lubricating Bronze Bushing Bearing

- 3 3. How to Replace FB090 Bronze Bushing Bearings: Step-by-Step Process

- 4 4. FB090 Heavy Duty Bronze Wrapped Bushing for Industrial Applications

- 5 5. Understanding FB090 Bronze Bushing Bearing Pricing Factors

1. Key Dimensions of the FB090 Bronze Wrapped Bushing Bearing

When selecting a FB090 bronze wrapped bushing bearing, understanding its precise dimensions is critical for ensuring compatibility with your machinery. The standard measurements typically include an inner diameter (ID), outer diameter (OD), and length, which must align with the housing and shaft specifications. Deviations in these dimensions can lead to improper fitment, accelerated wear, or even mechanical failure.

The inner diameter is particularly important because it determines the shaft size the bushing can accommodate. A mismatch here could cause excessive friction or looseness, both of which compromise performance. Meanwhile, the outer diameter must fit snugly within the bearing housing without requiring excessive force during installation. The length of the bushing affects load distribution—shorter bushings may concentrate stress, while longer ones provide better stability but require precise alignment.

In some industrial applications, modifications to standard dimensions may be necessary. For instance, heavy-duty equipment might require a slightly thicker wall for increased durability, while high-speed applications could benefit from tighter tolerances to minimize vibration. Engineers should always consult technical datasheets and, if possible, physically verify dimensions before finalizing a purchase.

Another consideration is thermal expansion. Bronze, like other metals, expands under heat, which can alter clearances during operation. In high-temperature environments, selecting a bushing with slightly adjusted dimensions—factoring in thermal growth—can prevent seizing or excessive play. Proper lubrication also plays a role in maintaining dimensional stability, as it reduces friction-induced heat buildup.

For those replacing an existing bushing, accurate measurement techniques are essential. Using calipers or micrometers, technicians should check both worn and unworn sections to account for any deformation. If the original bushing is no longer available, cross-referencing FB090 bronze wrapped bushing bearing dimensions with manufacturer catalogs or industry standards can help identify suitable alternatives.

2. Advantages and Applications of the FB090 Self-Lubricating Bronze Bushing Bearing

The FB090 self-lubricating bronze bushing bearing is engineered to minimize maintenance while maximizing service life in demanding environments. Unlike traditional bushings that require frequent grease replenishment, self-lubricating variants embed solid lubricants within the bronze matrix, which are gradually released during operation. This design significantly reduces downtime and operational costs.

One of the primary benefits of this technology is its ability to perform in extreme conditions. High-temperature settings, such as those found in steel mills or power generation plants, can degrade conventional lubricants, leading to premature failure. The FB090's solid lubricants remain effective even at elevated temperatures, ensuring consistent performance. Similarly, in dusty or wet environments where liquid lubricants might wash away or attract contaminants, the self-lubricating feature maintains smooth operation without external intervention.

Another key advantage is load distribution. The bronze alloy provides excellent compressive strength, allowing the bushing to handle heavy radial and axial loads without deforming. When combined with the self-lubricating properties, this makes the FB090 ideal for oscillating or slow-rotation applications where boundary lubrication is common. Examples include hydraulic cylinder joints, construction equipment pivots, and agricultural machinery linkages.

Compared to polymer-based or plain bronze bushings, the FB090 offers superior wear resistance. The embedded lubricants create a protective film between the bushing and shaft, reducing metal-to-metal contact. This not only extends component life but also minimizes shaft wear, which can be a costly issue in high-precision machinery. Additionally, the absence of external grease reduces the risk of contamination in clean industries like food processing or pharmaceuticals.

When selecting a self-lubricating bushing, engineers should evaluate factors such as PV (pressure-velocity) limits, environmental exposure, and expected lifespan. The FB090 bronze bushing bearing replacement cycle can be significantly longer than traditional options, but proper installation and alignment remain crucial to achieving optimal performance.

3. How to Replace FB090 Bronze Bushing Bearings: Step-by-Step Process

Replacing a FB090 bronze bushing bearing replacement requires careful attention to detail to ensure proper function and longevity. The process begins with thorough preparation, including gathering the right tools and ensuring the work area is clean. Essential tools typically include bearing pullers, hydraulic presses, alignment tools, and appropriate lubrication.

The first step is the safe removal of the old bushing. This often requires specialized extraction tools to avoid damaging the housing. For stubborn bushings, applying heat to the outer housing can help with removal by causing slight expansion. However, temperature must be carefully controlled to prevent damage to surrounding components. Once removed, the housing should be thoroughly cleaned and inspected for wear or damage that might affect the new bushing's performance.

Installation of the new FB090 bushing demands precision. The bushing should be properly aligned before pressing it into place. Using a press with controlled force is crucial to avoid deformation. Some technicians recommend freezing the bushing before installation to slightly reduce its size, making insertion easier while ensuring a tight fit when it returns to ambient temperature. Proper alignment must be verified throughout the installation process.

Post-installation checks are equally important. The shaft should rotate smoothly without binding, and there should be no visible gaps between the bushing and housing. Initial lubrication may be required even for self-lubricating models during the break-in period. Finally, documenting the replacement with details such as date, installation torque, and any observations creates valuable maintenance records for future reference.

4. FB090 Heavy Duty Bronze Wrapped Bushing for Industrial Applications

The FB090 heavy duty bronze wrapped bushing is specifically designed to withstand the rigorous demands of industrial environments. Its construction features high-grade bronze alloys reinforced to handle extreme pressures and loads that would quickly degrade standard bushings. These components are essential in industries where equipment operates continuously under substantial stress.

Mining equipment represents one of the most demanding applications for these bushings. The constant vibration, abrasive dust, and heavy loads in mining machinery require bushings that can maintain integrity under punishing conditions. The FB090's material composition and design provide the necessary durability, with the added benefit of reduced maintenance needs compared to conventional alternatives.

Construction machinery similarly benefits from these heavy-duty bushings. Excavators, cranes, and bulldozers subject their components to variable loads and frequent movement changes. The FB090's ability to handle both radial and axial forces makes it ideal for pivot points and joint applications in such equipment. Its wear resistance translates to longer service intervals, reducing downtime and maintenance costs.

Marine applications present another challenging environment where the FB090 excels. Saltwater exposure can rapidly corrode standard components, but the bronze alloy's natural corrosion resistance combined with specialized coatings available on some models provides exceptional protection. Whether in propulsion systems or deck machinery, these bushings deliver reliable performance in conditions that would quickly degrade lesser components.

5. Understanding FB090 Bronze Bushing Bearing Pricing Factors

When evaluating the FB090 bronze bushing bearing price list, several factors influence cost variations. Material composition represents a primary determinant, with higher-grade bronze alloys commanding premium prices but offering superior performance characteristics. The manufacturing process also affects pricing - precision-machined bushings typically cost more than cast versions but provide better dimensional accuracy and surface finish.

Quantity discounts play a significant role in procurement costs. Bulk purchases often reduce per-unit prices substantially, making them attractive for operations requiring multiple replacements or maintaining inventory. However, buyers must balance this against storage costs and the risk of obsolescence if specifications change.

Market conditions and raw material prices cause fluctuations in bushing costs. Bronze prices tied to copper markets can vary, affecting the final product price. Additionally, specialized features like custom coatings or non-standard dimensions increase costs but may be necessary for specific applications. Buyers should consider total cost of ownership rather than just purchase price, factoring in expected lifespan and maintenance requirements.

Quality verification is essential when comparing prices. Lower-cost alternatives may seem attractive initially but could lead to premature failure and higher long-term costs. Reputable suppliers typically provide material certifications and performance data to validate their products' quality. For critical applications, investing in higher-quality bushings often proves more economical over the equipment's lifecycle despite higher upfront costs.