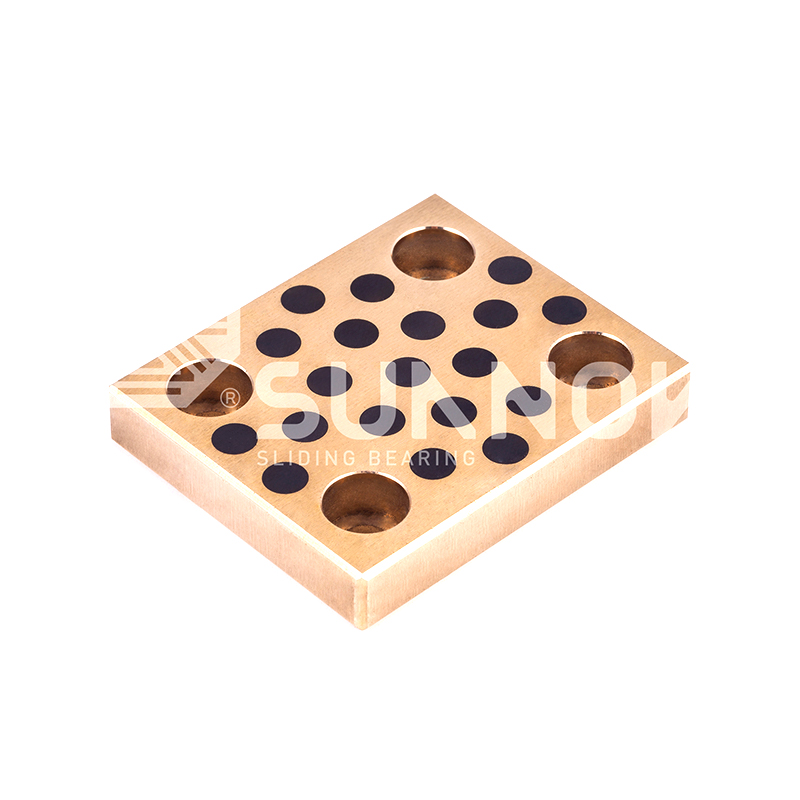

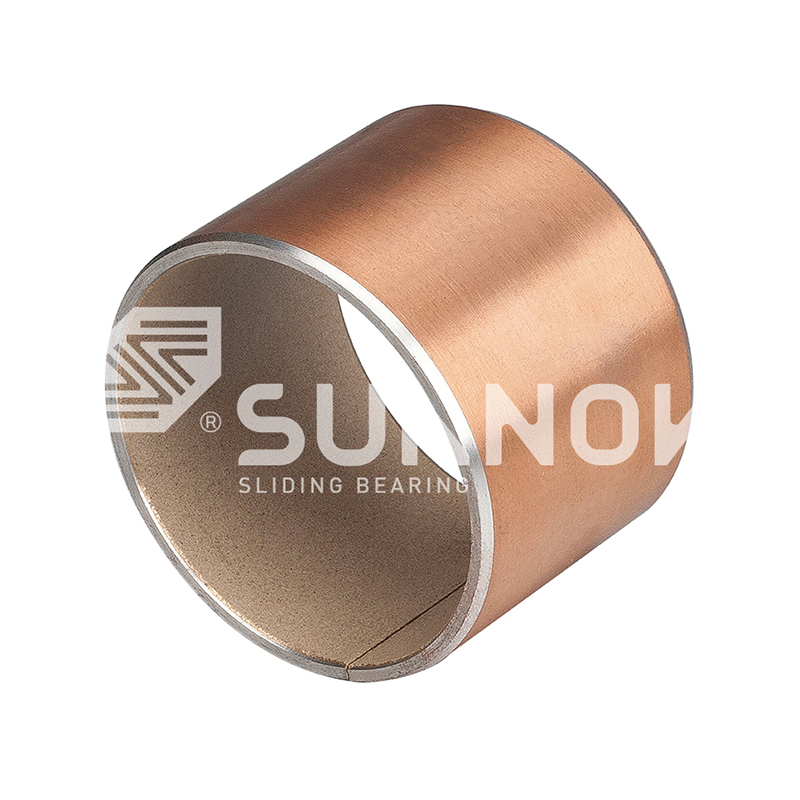

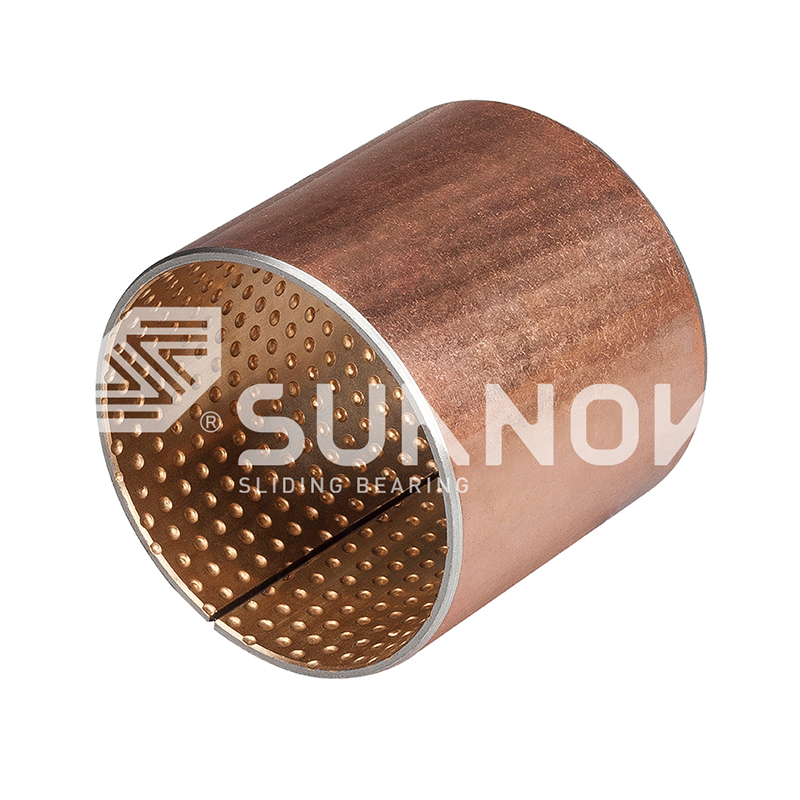

The JF-700 Bi-Metal Bearing is a premium-grade self-lubricating sleeve bushing designed for heavy-duty industrial applications where reliability and longevity are critical. These durable industrial bushings combine high load capacity with maintenance-free operation, making them ideal for harsh operating conditions.

- Maintenance-free operation: Embedded solid lubricants provide continuous lubrication

- Exceptional wear resistance: Bi-metal construction extends service life

- High load capacity: Withstands heavy radial and axial loads

- Corrosion resistant: Performs well in wet or corrosive environments

- Temperature resistant: Stable performance from -40°F to 300°F (-40°C to 150°C)

- Cost-effective solution: Reduces downtime and maintenance costs

The JF-700 bi-metal bushings are widely used in demanding applications across various industries:

- Construction equipment: Excavators, loaders, cranes

- Agricultural machinery: Tractors, combines, harvesters

- Material handling: Conveyor systems, forklifts

- Heavy trucks: Suspension systems, fifth wheels

- Industrial machinery: Pumps, compressors, hydraulic cylinders

- Marine applications: Deck machinery, steering systems

Why Choose Our Bi-Metal Sleeve Bearings?

Our JF-700 heavy duty bushings stand out from competitors through:

- Superior material quality: Precision-engineered alloy composition for optimal performance

- Advanced manufacturing: Consistent quality through automated production processes

- Customization options: Available in standard and custom sizes to fit your exact requirements

- Proven durability: Extensive testing ensures reliable performance in extreme conditions

- Technical support: Our engineering team can help with bearing selection and application advice

Installation and Maintenance Guidelines

For optimal performance of your self-lubricating sleeve bearings:

- Ensure proper alignment during installation

- Clean housing surfaces before assembly

- Use appropriate installation tools to prevent damage

- Check for proper clearance after installation

- Regularly inspect for abnormal wear (though no lubrication is required)

Frequently Asked Questions

Q: What makes bi-metal bushings different from regular bronze bushings?

A: Bi-metal bushings combine the strength of a steel backing with the wear resistance of a bronze layer, offering higher load capacity and longer service life.

Q: How long do these self-lubricating bushings typically last?

A: Service life varies by application, but typically lasts 3-5 times longer than conventional lubricated bushings in similar conditions.

Q: Can these bearings be used in food processing equipment?

A: Standard JF-700 bushings are not food-grade. Ask about our NSF-certified options for food industry applications.

Q: Do you offer custom sizes or special configurations?

A: Yes, we can manufacture bushings to your exact specifications including special materials, flanges, or unique dimensions.