-

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing -

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing -

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing -

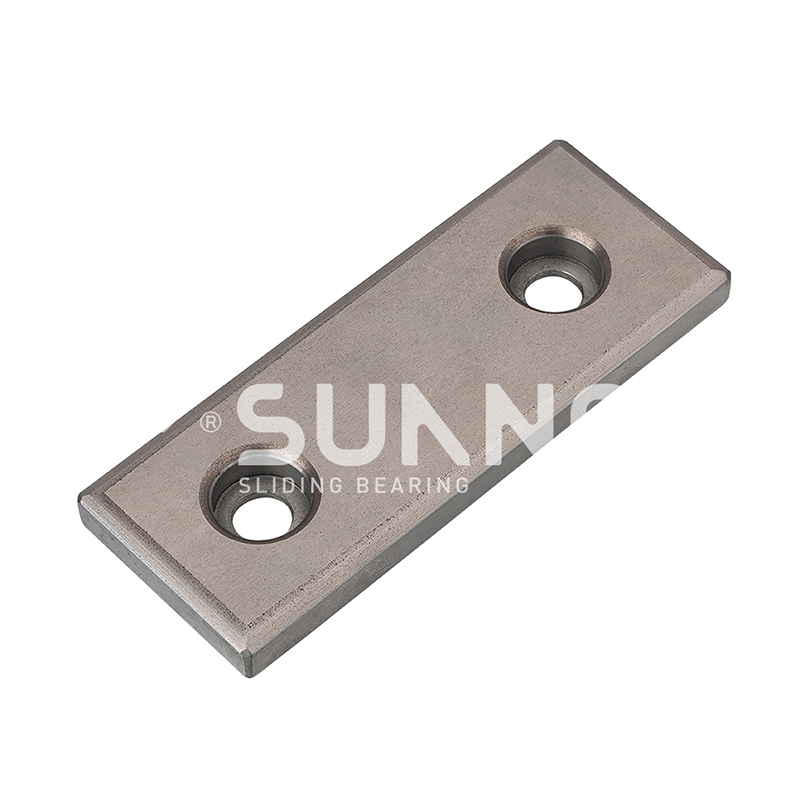

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications

Oil-retaining Bimetallic Bearing Oil-Retaining 200#P10 Wear Plate - High Load Bearing, Low Friction Steel Plate for Industrial Applications -

SF-1 Oilless Bearing Self Lubricating SF-1T Metal Gear Pump Bearing Bronze Bushings

SF-1 Oilless Bearing Self Lubricating SF-1T Metal Gear Pump Bearing Bronze Bushings -

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush -

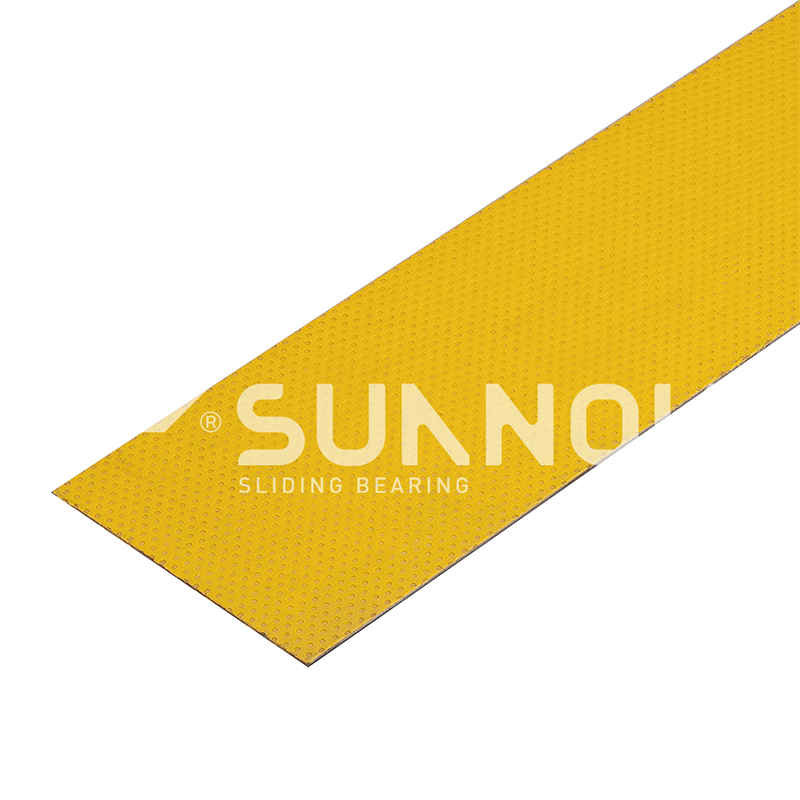

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE -

Self-Lubricating Copper Alloy Bearings: A Comparative Analysis with JDB-600 Casting Bronze and Oil-Retaining Bimetallic Bearings

Industry News-Self-lubricating copper alloy bearings are widely used in industrial applications due to their excellent wear resistance, low friction, and maintenance-free operation. This article explores their properties, advantages, and compares them with two other popular bearing materials: JDB-600 Casting Bronze Bearings and Oil-Retaining Bimetallic Bearings.

Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing

1. Self-Lubricating Copper Alloy Bearings

Key Features:

Material Composition: Copper alloy matrix embedded with solid lubricants (graphite, PTFE, or MoS₂).

Self-Lubrication: Reduces friction without external oil supply.

Applications: High-load, low-speed environments (e.g., construction machinery, automotive components).

Advantages:

Maintenance-free operation.

High wear resistance.

Suitable for dusty or high-temperature conditions.

2. JDB-600 Casting Bronze Bearing

Key Features:

Material Composition: High-strength bronze alloy with embedded solid lubricants.

Load Capacity: Higher than standard copper alloys.

Applications: Heavy machinery, mining equipment.

Advantages:

Excellent impact resistance.

Long service life under extreme pressure.

3. Oil-Retaining Bimetallic Bearing

Key Features:

Material Composition: Steel backing with porous bronze layer (oil-impregnated).

Lubrication Mechanism: Releases oil during operation.

Applications: High-speed rotating machinery (e.g., motors, pumps).

Advantages:

Self-lubricating but requires occasional oil replenishment.

Good heat dissipation.

Parameter Comparison

| Property | Self-Lubricating Copper Alloy | JDB-600 Casting Bronze | Oil-Retaining Bimetallic |

|---|---|---|---|

| Max Load (MPa) | 60-100 | 70-120 | 50-80 |

| Max Speed (m/s) | 0.5-2 | 0.3-1.5 | 2-6 |

| Operating Temp. (°C) | -200 to +280 | -100 to +300 | -50 to +150 |

| Lubrication Requirement | None | None | Oil replenishment needed |

| Main Applications | Heavy load, low speed | Extreme pressure | High-speed rotation |

Self-lubricating copper alloy bearings offer a maintenance-free solution for heavy-load applications, while JDB-600 Casting Bronze Bearings excel in extreme pressure conditions. Oil-Retaining Bimetallic Bearings are better suited for high-speed operations but require periodic lubrication. The choice depends on load, speed, and environmental conditions.