-

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings -

JDB Solid-lubricating Bearing GB61 Copper NAAMS Standard Flanged Solid-lubricating Bearing

JDB Solid-lubricating Bearing GB61 Copper NAAMS Standard Flanged Solid-lubricating Bearing -

JDB Solid-lubricating Bearing JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing

JDB Solid-lubricating Bearing JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing -

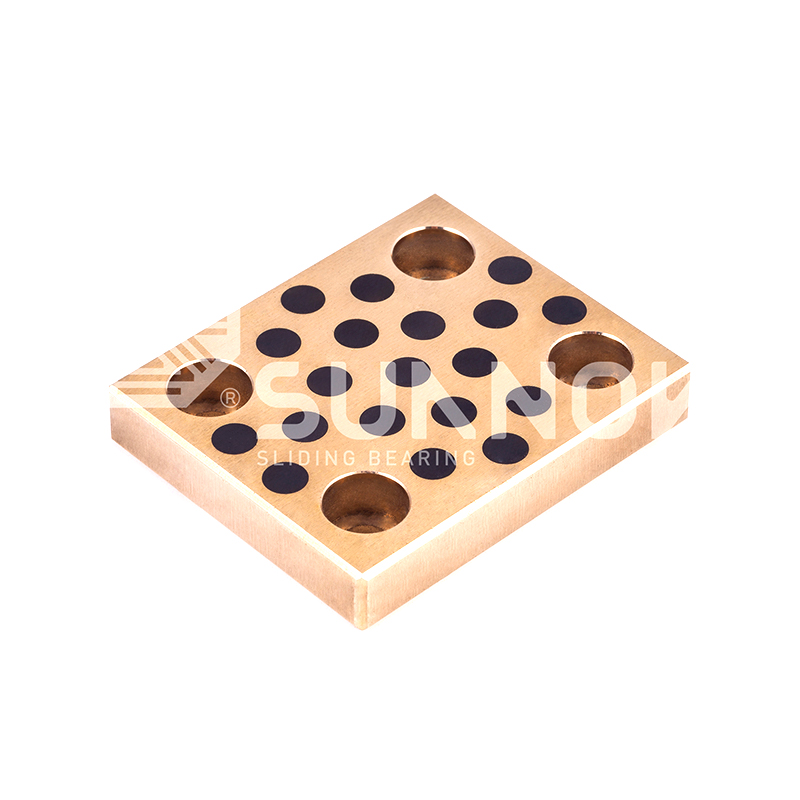

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate -

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing -

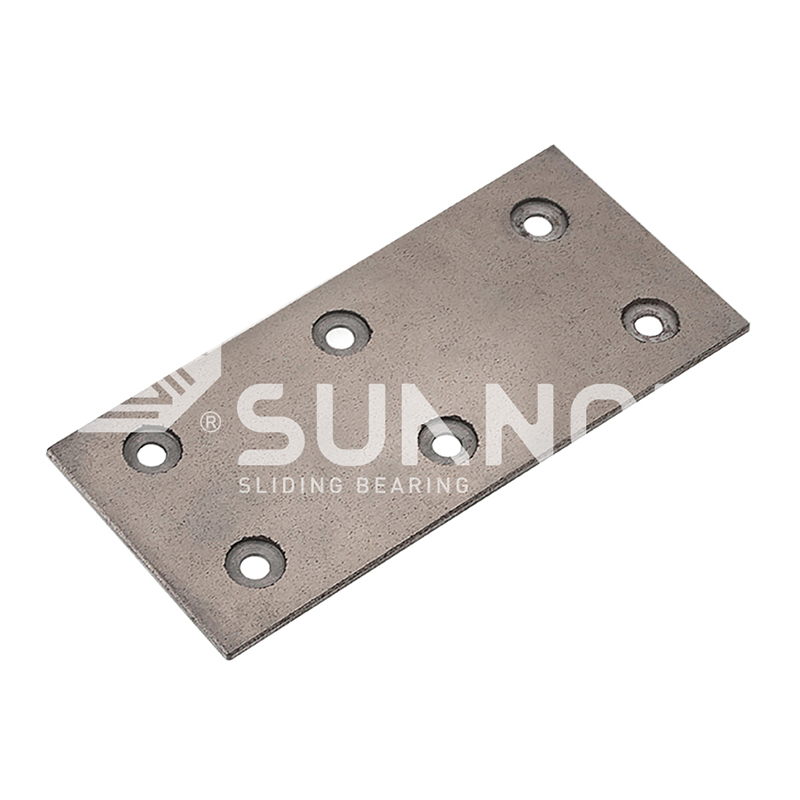

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface -

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers -

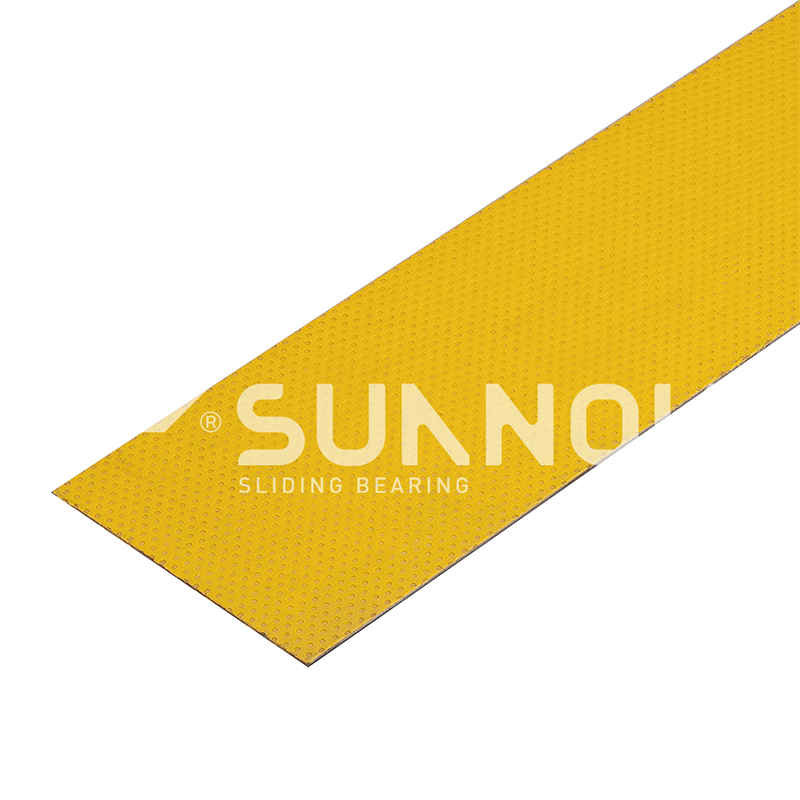

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

SF-2 Boundary Lubricating Bearing SF-2SP Standard Metric Size Self Lubricating Wear Strip With PTFE

Solid-Lubricating Bearing: The Future of Low-Maintenance Machinery

Industry News-In industrial applications, bearings play a crucial role in reducing friction and ensuring smooth operation. Among various bearing types, Solid-Lubricating Bearings have gained popularity due to their self-lubricating properties, reducing maintenance needs.

JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing

Solid-Lubricating Bearings: Key Features

Solid-lubricating bearings are designed with embedded lubricants (such as graphite, PTFE, or molybdenum disulfide) within their structure, eliminating the need for external lubrication. Key benefits include:

Maintenance-free operation – No need for frequent oil or grease replenishment.

High load capacity – Suitable for heavy-duty applications.

Corrosion and dust resistance – Ideal for harsh environments.

Extended lifespan – Reduced wear due to embedded lubrication.

Common Applications:

Aerospace components

Food processing machinery

Automotive suspensions

High-temperature industrial equipment

Comparison with FB090 Bronze Wrapped Bushing Bearings & Ball Bearing Cages

| Parameter | Solid-Lubricating Bearing | FB090 Bronze Wrapped Bushing Bearing | Ball Bearing Cage |

|---|---|---|---|

| Lubrication Type | Self-lubricating (embedded) | Requires external lubrication | Requires grease/oil |

| Maintenance Needs | Low | Moderate to high | High |

| Load Capacity | High (static & dynamic) | Moderate | High (dynamic) |

| Speed Performance | Moderate | Low to moderate | High |

| Corrosion Resistance | Excellent | Good (bronze resists corrosion) | Varies (depends on material) |

| Best For | Harsh, high-load environments | Moderate-load, low-speed applications | High-speed, precision applications |

While Ball Bearing Cages excel in high-speed applications and FB090 Bronze Wrapped Bushings offer reliable performance in moderate conditions, Solid-Lubricating Bearings stand out in environments requiring minimal maintenance and high durability. Choosing the right bearing depends on factors like load, speed, and environmental conditions—making solid-lubricating bearings an excellent choice for industries prioritizing efficiency and longevity.