-

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing -

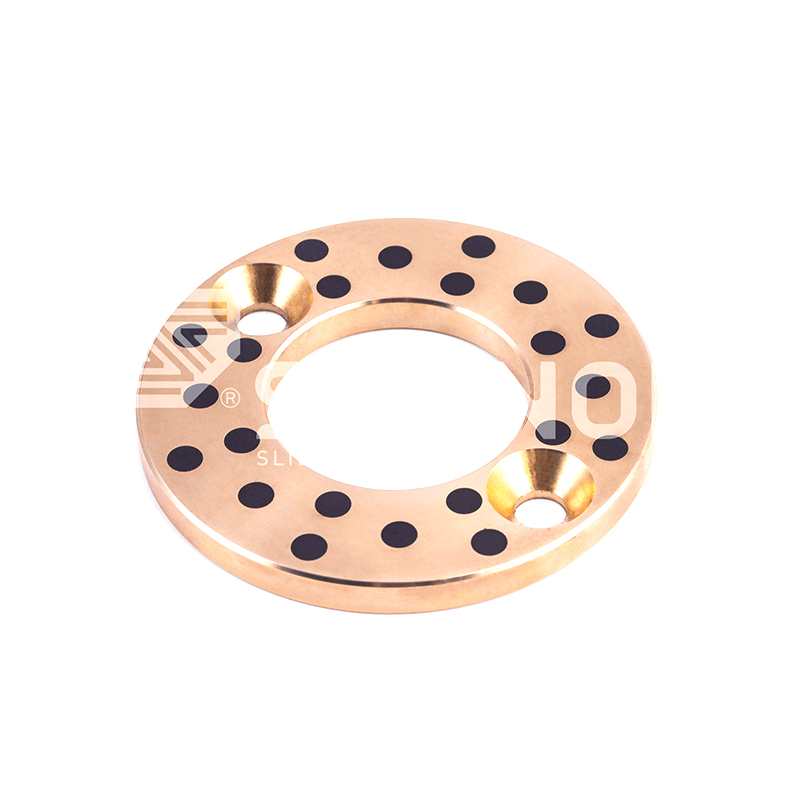

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing -

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings

JDB Solid-lubricating Bearing JGBF Brass Oilless Ejector Flanged Guide Bearings Bushings -

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing -

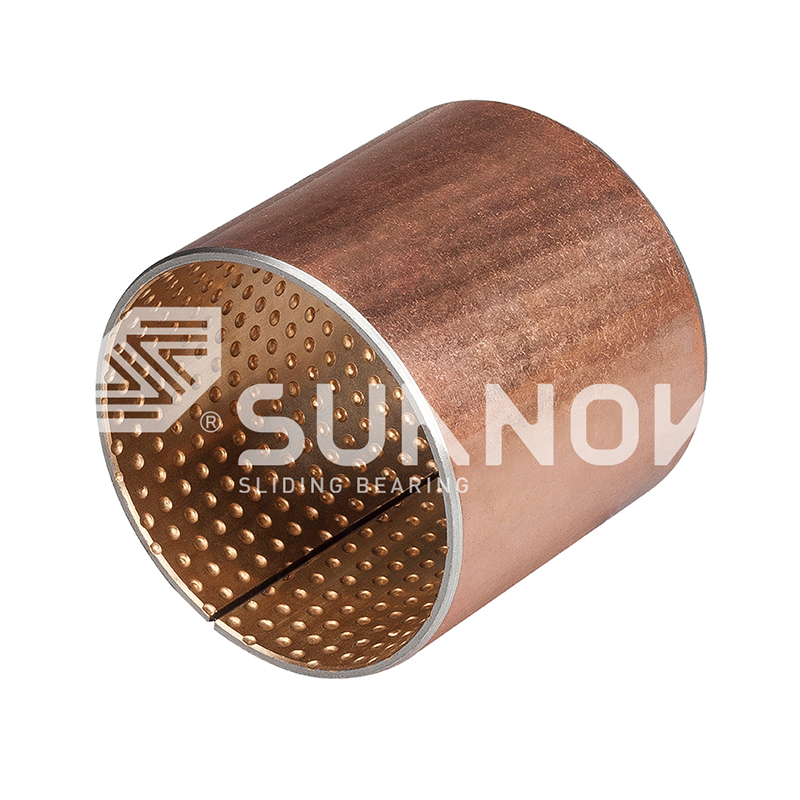

JDB Solid-lubricating Bearing JEGB/JEGBK Oiless Ejector Guide Bushing Oilless Ejector Bearing

JDB Solid-lubricating Bearing JEGB/JEGBK Oiless Ejector Guide Bushing Oilless Ejector Bearing -

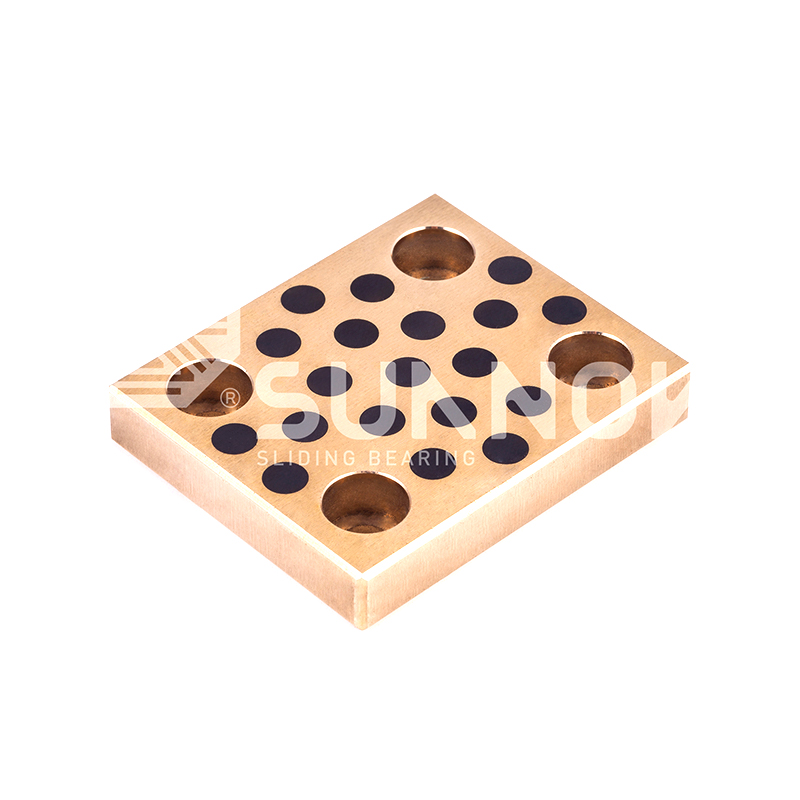

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate -

-

The Benefits of Self-Lubricating Copper Alloy Bearings in Reducing Maintenance Costs

Industry News-Introduction to Self-Lubricating Copper Alloy Bearings

What Are Self-Lubricating Copper Alloy Bearings?

Self-lubricating copper alloy bearings are advanced bearing solutions that combine the strength and durability of copper alloys with self-lubricating materials. These bearings are designed to reduce friction and wear without the need for external lubrication. The embedded lubrication materials ensure smooth operation, minimizing the need for regular maintenance and extending the lifespan of the bearings.

How They Differ from Traditional Bearings

Unlike traditional bearings that rely on external lubricants such as oil or grease, self-lubricating copper alloy bearings have internal lubricants embedded in the material. This unique design eliminates the need for regular lubrication maintenance and provides several advantages, including reduced operational downtime, lower maintenance costs, and improved overall efficiency in machinery operation.

JEGB/JEGBK Oiless Ejector Guide Bushing Oilless Ejector Bearing

Key Benefits of Self-Lubricating Copper Alloy Bearings in Reducing Maintenance Costs

Lower Maintenance Requirements

One of the main benefits of self-lubricating copper alloy bearings is their ability to reduce maintenance requirements. Because these bearings do not require regular lubrication, maintenance teams can focus on other critical tasks. This significantly reduces downtime and prevents production delays caused by lubrication failures.

- No need for regular lubrication, reducing labor costs

- Lower risk of bearing failure due to lack of lubrication

- Fewer components to maintain, leading to reduced maintenance efforts

Increased Longevity and Reduced Downtime

Self-lubricating copper alloy bearings are designed to withstand prolonged use in high-load and high-temperature environments. The inherent properties of copper alloys, combined with the self-lubricating features, lead to a significant increase in bearing lifespan. This increased longevity helps reduce the frequency of replacements and the associated costs.

- Extended operational lifespan reduces the frequency of bearing replacements

- Fewer interruptions in operations due to less bearing failure

- Improved reliability in harsh industrial conditions

Reduced Lubrication Costs

Traditional bearings often require periodic lubrication to function properly, which can lead to ongoing expenses related to lubricant purchase, storage, and application. Self-lubricating bearings eliminate these costs by providing continuous lubrication from within the bearing material. This results in significant savings over time, especially in industries with large-scale machinery fleets.

- No recurring costs for purchasing lubricants

- Reduced waste from lubricant disposal

- Minimized downtime for lubrication application

Applications of Self-Lubricating Copper Alloy Bearings

Heavy Machinery and Industrial Equipment

Self-lubricating copper alloy bearings are particularly beneficial in industries where heavy machinery is used. For example, construction equipment, mining machinery, and industrial manufacturing processes require bearings that can withstand high loads and continuous operation. The self-lubricating feature ensures that these bearings continue to perform reliably without requiring constant maintenance.

- Ideal for mining, construction, and material handling machinery

- Enhance the performance of heavy-duty industrial equipment

- Minimize the risk of bearing failure in high-load applications

Automotive and Aerospace Industries

In the automotive and aerospace industries, where precision and reliability are crucial, self-lubricating copper alloy bearings offer significant advantages. These industries rely on bearings that can perform in extreme temperatures and under high stress without the need for constant lubrication.

- Used in high-performance engines and aerospace components

- Reduce maintenance costs in automotive and aircraft systems

- Ensure reliability in high-precision applications

How to Maximize the Benefits of Self-Lubricating Copper Alloy Bearings

Proper Selection for Specific Applications

To fully maximize the benefits of self-lubricating copper alloy bearings, it is crucial to choose the right bearing for the application. Factors like load capacity, temperature range, and environmental conditions must be considered to ensure optimal performance. Selecting the correct bearing will ensure the system operates efficiently and lasts longer without additional costs.

Regular Monitoring and Maintenance for Longevity

Although these bearings are maintenance-free, regular monitoring is still essential. This ensures that the bearings continue to operate as intended and allows for early detection of any issues before they cause significant damage. Monitoring bearing performance can help maintain the efficiency of the machinery and extend the bearing's life even further.

FAQ

What are the key benefits of self-lubricating copper alloy bearings?

The key benefits include reduced maintenance costs, increased bearing lifespan, no need for regular lubrication, and enhanced operational efficiency in demanding environments. These bearings also help reduce downtime by eliminating the need for frequent lubrication checks.

How do self-lubricating copper alloy bearings reduce maintenance costs?

By eliminating the need for external lubrication, self-lubricating copper alloy bearings save on lubricant costs, reduce maintenance labor, and extend bearing life. These factors combine to lower overall maintenance expenses in the long run.

Can self-lubricating copper alloy bearings be used in heavy machinery?

Yes, self-lubricating copper alloy bearings are ideal for heavy machinery applications. Their ability to withstand high loads and harsh conditions without requiring constant lubrication makes them a perfect choice for industries like construction, mining, and industrial manufacturing.