-

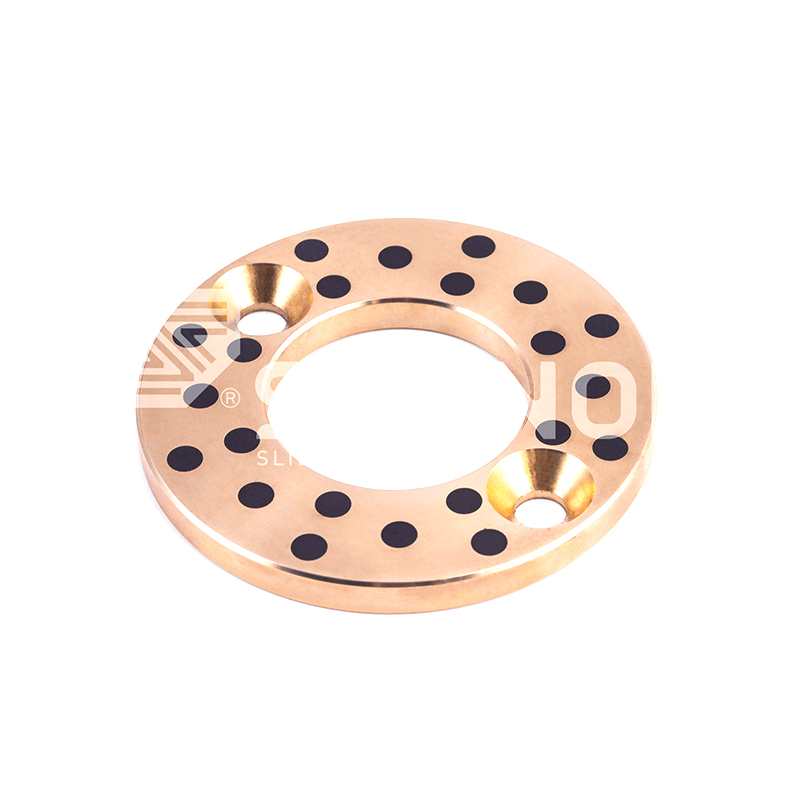

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing

JDB Solid-lubricating Bearing JFB650 Metric Oil Free Self Lubricating Bronze Round Flanged Bearing -

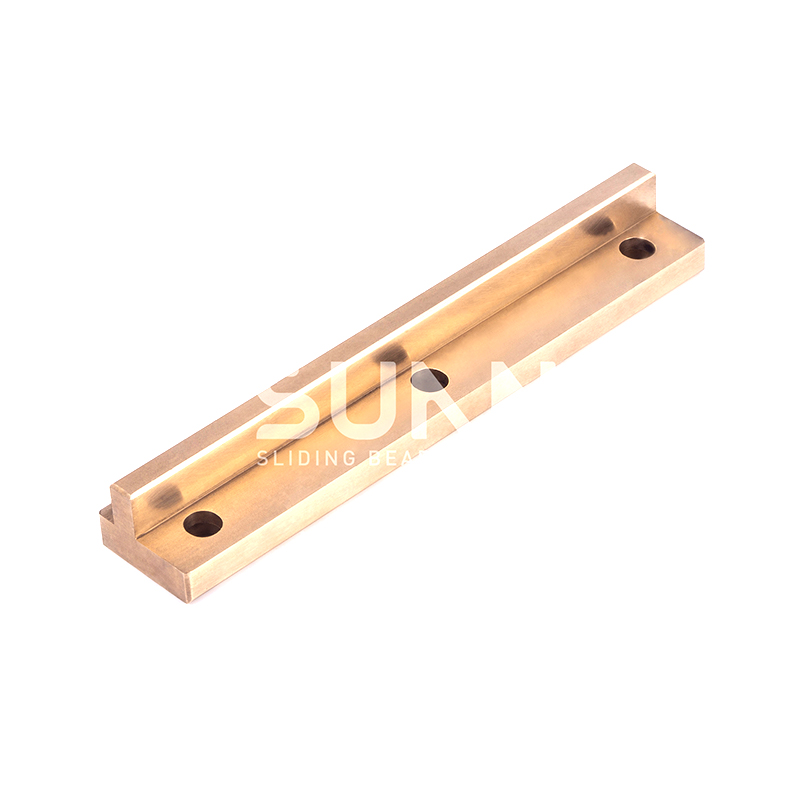

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing

JDB Solid-lubricating Bearing JOSG Ejector Guide Bushings Solid-Self-Lubricating Bearing -

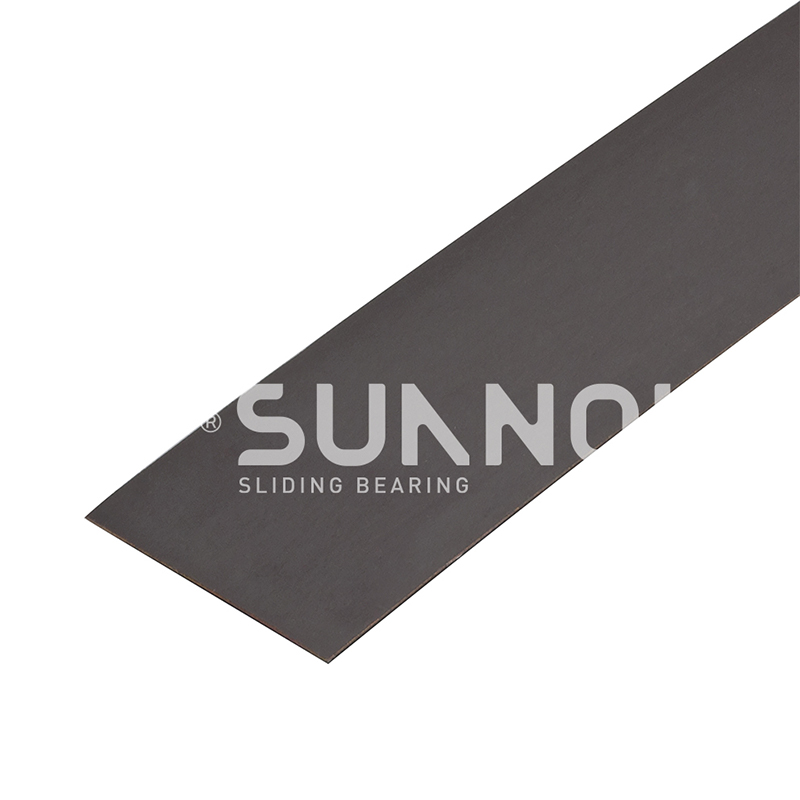

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components -

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing

JDB-600 Casting Bronze Bearing JDB-600 Cast Self-Lubricating Bronze Guide Bushing Bearing -

-

SF-1 Oilless Bearing Self Lubricating SF-1T Metal Gear Pump Bearing Bronze Bushings

SF-1 Oilless Bearing Self Lubricating SF-1T Metal Gear Pump Bearing Bronze Bushings -

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip -

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

Oilless Thrust Washers: The Ultimate Guide to Maintenance-Free Bearing Solutions

Industry News-- 1 Understanding the Basics of Oilless Thrust Washers

- 2 Exploring Self-Lubricating Thrust Washer Materials

- 3 High Temperature Thrust Washer Options for Demanding Applications

- 4 Thrust Washer Wear Resistance and Longevity Factors

- 5 PTFE Thrust Washer Benefits in Specialized Applications

- 6 Installation and Maintenance Best Practices for Oilless Thrust Washers

Understanding the Basics of Oilless Thrust Washers

Thrust washers are essential components in various mechanical systems, designed to handle axial loads while allowing rotational movement between parts. The oilless thrust washer represents a significant advancement in bearing technology, eliminating the need for constant lubrication while maintaining excellent performance characteristics.

JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing

What Makes Oilless Thrust Washers Unique

Unlike traditional thrust washers that require regular oiling or greasing, oilless thrust washers incorporate special materials and designs that provide inherent lubrication properties. These self-lubricating components typically feature:

- Embedded solid lubricants within their matrix structure

- Special polymer composites with low friction coefficients

- Porous metal substrates impregnated with lubricants

- Advanced surface treatments that reduce wear

Key Advantages of Oilless Technology

The transition to oilless thrust washer solutions offers numerous benefits for mechanical systems:

- Elimination of maintenance requirements for lubrication

- Reduced contamination risks in clean environments

- Improved reliability in inaccessible or hard-to-service locations

- Consistent performance across temperature variations

- Longer service life compared to conventional lubricated washers

Exploring Self-Lubricating Thrust Washer Materials

The performance of oilless thrust washers largely depends on their material composition. Modern manufacturing has developed several advanced material options that provide excellent wear resistance and self-lubricating properties.

Common Material Choices for Oilless Washers

When selecting self-lubricating thrust washer materials, engineers typically consider these options:

| Material Type | Key Properties | Ideal Applications |

|---|---|---|

| PTFE-Based Composites | Excellent chemical resistance, low friction | Food processing, chemical handling |

| Bronze-Graphite | High load capacity, good thermal conductivity | Heavy machinery, industrial equipment |

| Polyimide Composites | High temperature resistance, dimensional stability | Aerospace, high-temperature environments |

| Metal-Polymer Hybrids | Combined strength and lubricity | Automotive, precision machinery |

Material Selection Considerations

Choosing the right self-lubricating thrust washer materials requires careful evaluation of several factors:

- Operating temperature range and thermal stability requirements

- Expected load conditions (static vs dynamic loads)

- Environmental exposure (chemicals, moisture, dust)

- Required service life and maintenance intervals

- Cost constraints and production volume considerations

High Temperature Thrust Washer Options for Demanding Applications

Many industrial applications require bearing components that can withstand elevated temperatures while maintaining performance. High temperature thrust washer options have been specifically developed to meet these challenging requirements.

Challenges in High-Temperature Environments

Standard oilless thrust washers may fail or degrade when exposed to excessive heat. High-temperature applications present several unique challenges:

- Thermal expansion affecting dimensional stability

- Accelerated wear at elevated temperatures

- Degradation of lubrication properties

- Material softening or structural changes

- Increased oxidation and chemical reactivity

Solutions for Thermal Management

Modern high temperature thrust washer options incorporate several design features to address thermal challenges:

- Special heat-resistant polymers with high melting points

- Thermal barrier coatings to protect underlying materials

- Enhanced heat dissipation through metal substrates

- Thermally stable solid lubricants that maintain effectiveness

- Compensatory designs accounting for thermal expansion

Thrust Washer Wear Resistance and Longevity Factors

The durability of oilless thrust washers is a critical consideration for any application. Understanding the factors that influence thrust washer wear resistance helps in selecting the optimal solution and predicting service life.

Key Wear Mechanisms in Thrust Washers

Several physical processes contribute to wear in thrust bearing applications:

- Abrasive wear from particulate contamination

- Adhesive wear from metal-to-metal contact

- Surface fatigue from repeated loading cycles

- Corrosive wear from chemical exposure

- Fretting wear from small oscillatory movements

Enhancing Wear Resistance

Manufacturers employ various techniques to improve thrust washer wear resistance in oilless designs:

| Technique | Benefit | Implementation |

|---|---|---|

| Surface Hardening | Increases surface durability | Case hardening, nitriding |

| Composite Materials | Combines multiple beneficial properties | Polymer-metal hybrids |

| Lubricant Impregnation | Provides continuous lubrication | Oil-filled porous metals |

| Precision Finishing | Reduces initial wear-in | Superfinishing, lapping |

PTFE Thrust Washer Benefits in Specialized Applications

Among the various material options available, PTFE-based oilless thrust washers offer unique advantages that make them particularly suitable for certain demanding applications.

Exceptional Properties of PTFE Washers

The PTFE thrust washer benefits stem from the remarkable characteristics of polytetrafluoroethylene and its composites:

- Extremely low coefficient of friction (as low as 0.05-0.10)

- Outstanding chemical resistance to most industrial chemicals

- Wide operating temperature range (-200°C to +260°C)

- Excellent dielectric properties for electrical applications

- Natural compliance that helps compensate for misalignment

Applications Highlighting PTFE Advantages

The unique combination of properties makes PTFE-based oilless thrust washers ideal for:

- Chemical processing equipment where corrosion resistance is critical

- Food and pharmaceutical applications requiring cleanliness

- Cryogenic systems operating at extremely low temperatures

- Electrical insulation applications in motors and generators

- Vacuum systems where outgassing must be minimized

Installation and Maintenance Best Practices for Oilless Thrust Washers

While oilless thrust washers eliminate the need for lubrication maintenance, proper installation and handling remain crucial for optimal performance and longevity.

Proper Installation Techniques

To ensure maximum performance from your oilless thrust washer, follow these installation guidelines:

- Clean all mating surfaces thoroughly before installation

- Verify proper alignment of components to avoid edge loading

- Follow recommended torque specifications for retaining hardware

- Check for proper clearance and preload conditions

- Use appropriate tools to avoid damaging the washer during installation

Monitoring and Replacement Considerations

Even with their maintenance-free design, oilless thrust washers should be periodically inspected:

- Establish regular inspection intervals based on operating conditions

- Monitor for signs of excessive wear or unusual noise

- Check for contamination that could accelerate wear

- Measure axial play to detect wear before failure occurs

- Keep records of service life to predict replacement timing