-

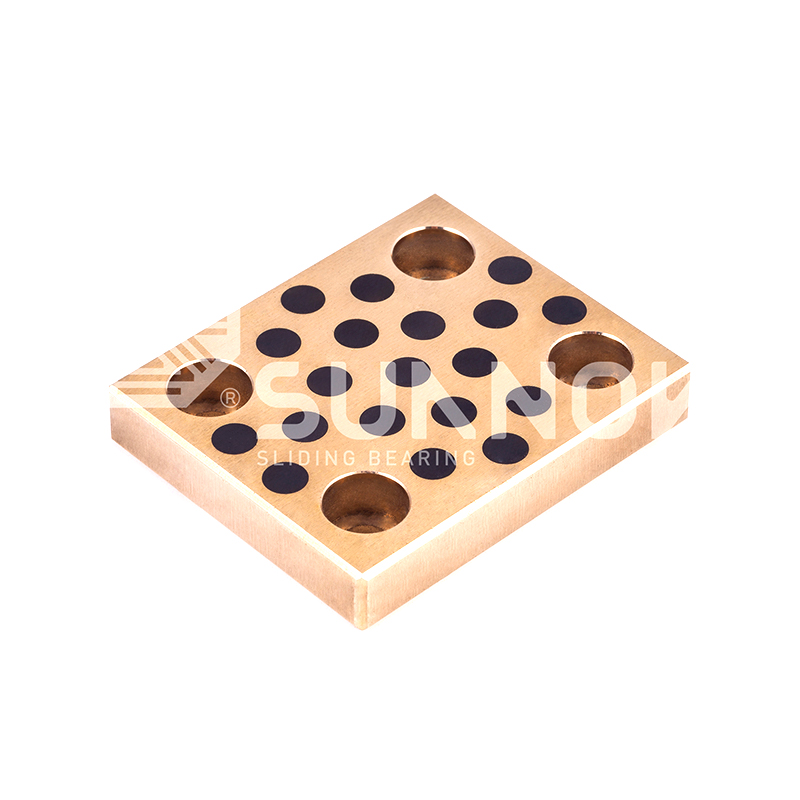

JDB Solid-lubricating Bearing High Temperature Brass JGB Oilless Ejector Guide Bearings

JDB Solid-lubricating Bearing High Temperature Brass JGB Oilless Ejector Guide Bearings -

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate

JDB Solid-lubricating Bearing JESW Oilless Wear Plate Lubrication-Free Sliding Plate -

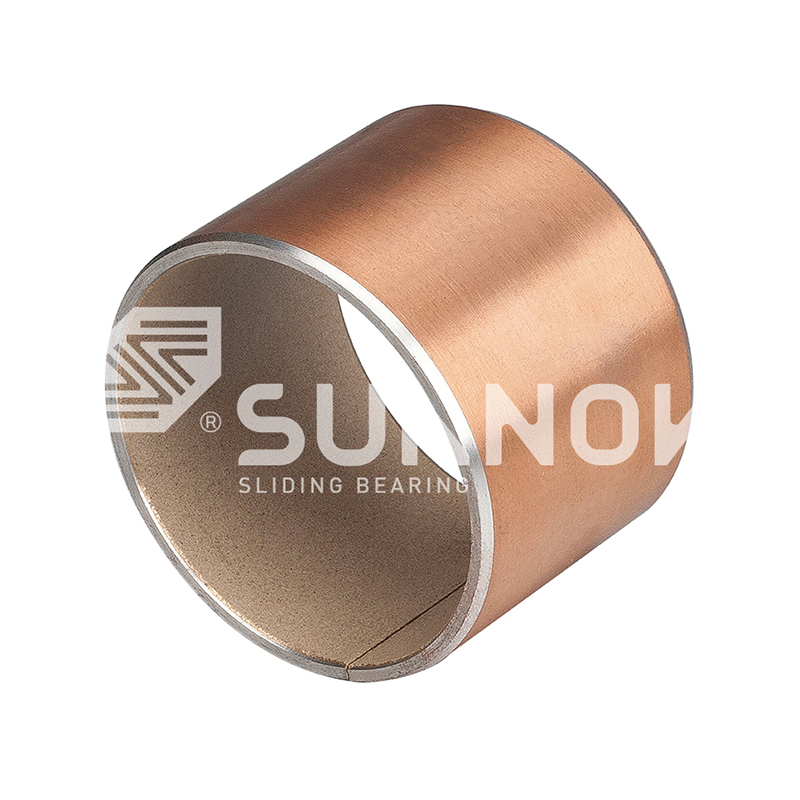

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed)

Oil-retaining Bimetallic Bearing 200#B Oil-Retaining Bimetallic Bearing (Steel Backing+Copper Sinter With Solid Lubricating Dispersed) -

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

-

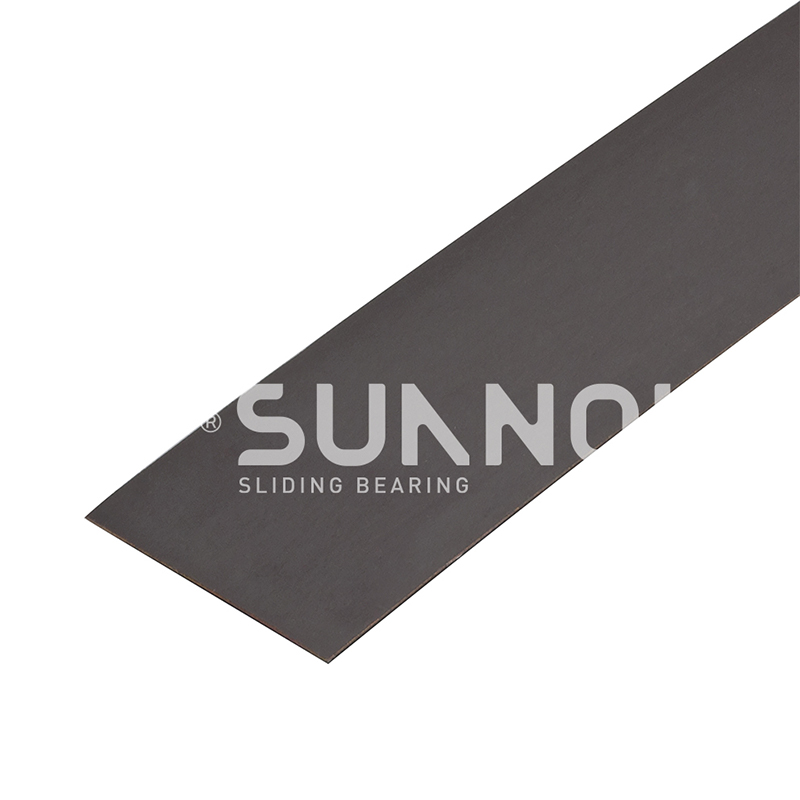

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip

SF-1 Oilless Bearing SF-1SP Strip Standard Metric Size Self-Lubricating Composite Slide Strip -

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers

SF-2 Boundary Lubricating Bearing SF-2WC Standard Metric Self-Lubricating Compound Thrust Washer Sliding Washers -

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

SF-1S Self-Lubricating Stainless Steel Bushings: Key Applications and Benefits

Industry News-- 1 1. SF-1S Self-Lubricating Bushings in High-Temperature Industrial Environments

- 2 2. Why Food & Beverage Machinery Needs Maintenance-Free Stainless Steel Bushings

- 3 3. Replacing Bronze Bushings with SF-1S Self-Lubricating Alternatives

- 4 4. High-Load Capacity of SF-1S Bushings: Where Standard Bearings Fail

- 5 5. Corrosion-Resistant SF-1S Bushings for Marine & Offshore Equipment

1. SF-1S Self-Lubricating Bushings in High-Temperature Industrial Environments

Industrial machinery operating in extreme heat demands components that can endure prolonged exposure to high temperatures without failure. Traditional lubricated bearings often degrade under such conditions, leading to frequent maintenance and unexpected downtime. SF-1S self-lubricating bushing for high temperature industrial applications provides a reliable solution, engineered to perform consistently even in environments exceeding 300°C.

SF-1S Self-Lubricating Stainless Steel Bushing Bearing - Maintenance Free, High Temperature Use

The unique composition of these bushings includes a stainless steel backing combined with a solid lubricant embedded within the material matrix. Unlike conventional bearings that rely on external grease or oil—which can evaporate or carbonize under extreme heat—the self-lubricating properties ensure continuous operation without the need for re-lubrication. This makes them particularly valuable in industries such as metal processing, where furnaces and kilns operate at sustained high temperatures.

A critical advantage of SF-1S bushings in high-heat scenarios is their resistance to thermal expansion-induced misalignment. Many standard bearings experience dimensional instability when subjected to fluctuating temperatures, leading to premature wear or seizure. However, the precision engineering of these bushings minimizes friction even under thermal stress, extending service life and reducing unplanned equipment stoppages.

Case studies from steel manufacturing plants highlight the efficiency gains achieved by switching to self-lubricating bushings. In rolling mills, where bearings are exposed to both high temperatures and heavy loads, traditional options required weekly lubrication checks and frequent replacements. After transitioning to maintenance-free stainless steel bearing bushings, facilities reported a 40% reduction in bearing-related downtime and a significant decrease in lubrication costs.

Additionally, these bushings are invaluable in applications involving dry or dusty environments where liquid lubricants attract contaminants. Cement plants, for example, benefit from their ability to operate smoothly without clogging from particulate matter. The elimination of external lubrication also reduces fire risks in high-temperature zones, making them a safer alternative in industries like glass production and chemical processing.

2. Why Food & Beverage Machinery Needs Maintenance-Free Stainless Steel Bushings

The food and beverage industry imposes strict hygiene and equipment reliability standards, making traditional lubricated bearings a potential liability. Maintenance-free stainless steel bearing bushings for food machinery address these challenges by combining corrosion resistance with self-lubrication, ensuring compliance with FDA and other regulatory requirements.

One of the primary concerns in food processing is contamination. Oil or grease-lubricated bearings can leak, introducing unwanted substances into production lines. Even food-grade lubricants require frequent reapplication, increasing maintenance labor and the risk of human error. SF-1S bushings eliminate this issue entirely, as their embedded lubricants do not migrate or degrade over time. This is particularly crucial in applications such as dough mixers, bottling lines, and meat processing conveyors, where bearing failure could lead to product recalls or sanitation violations.

Another critical factor is the corrosive nature of many food industry environments. Washdown procedures using acidic or chlorine-based cleaners can rapidly degrade standard bearings, leading to rust and premature failure. Stainless steel construction provides inherent resistance to these chemicals, ensuring longevity even in wet conditions. For example, in dairy processing plants, where equipment is routinely exposed to lactic acid and hot water, corrosion-resistant SF-1S bushings for marine equipment (though designed for saltwater) also prove highly effective due to their similar resistance properties.

Beyond contamination and corrosion, operational efficiency is a major consideration. Conveyor systems in packaging facilities run continuously, and unexpected bearing failures can halt entire production lines. The self-lubricating nature of these bushings reduces friction-related wear, allowing for smoother operation over extended periods. Real-world data from beverage canning plants shows that switching to maintenance-free bushings reduced bearing replacement intervals by over 60%, translating into substantial cost savings and improved throughput.

Finally, the ability of these bushings to operate without external lubrication makes them ideal for extreme-temperature food processing, such as industrial baking or freezing tunnels. Unlike traditional bearings, which may stiffen or fail in sub-zero conditions, SF-1S bushings maintain consistent performance, ensuring reliability across a wide operational range.

3. Replacing Bronze Bushings with SF-1S Self-Lubricating Alternatives

The industrial sector is increasingly recognizing the limitations of traditional bronze bushings, particularly in applications demanding higher performance and lower maintenance. SF-1S bronze-free self-lubricating bearings replacement offers a superior solution that addresses the shortcomings of conventional bronze components while delivering enhanced durability and operational efficiency.

Bronze bushings have long been the standard in many industrial applications due to their good wear characteristics and machinability. However, they suffer from several inherent drawbacks that become apparent in demanding environments. Most notably, bronze bushings require regular lubrication to prevent excessive wear and seizure, creating maintenance burdens and potential points of failure in automated systems. The SF-1S bushings overcome these limitations through their innovative self-lubricating design, which maintains optimal performance without external lubrication.

One of the most significant advantages of switching to SF-1S bushings is the dramatic reduction in maintenance requirements. Bronze bushings typically need frequent lubrication intervals, especially in high-load or high-speed applications. This not only increases labor costs but also creates opportunities for human error in lubrication procedures. The self-lubricating properties of SF-1S bushings eliminate these concerns, providing consistent performance throughout their service life with no need for manual intervention.

Performance under heavy loads represents another area where SF-1S bushings outperform their bronze counterparts. While bronze has good compressive strength, it can deform under sustained heavy loads, particularly in high-temperature environments. The stainless steel construction of SF-1S bushings provides superior load-bearing capacity, making them ideal for applications like hydraulic presses, construction equipment, and heavy machinery where high load capacity self-lubricating stainless steel bushings are essential for reliable operation.

The corrosion resistance of SF-1S bushings further extends their advantages over bronze components. Bronze can develop surface oxidation and corrosion in humid or chemically aggressive environments, leading to increased friction and premature failure. The stainless steel composition of SF-1S bushings provides excellent resistance to rust and chemical attack, ensuring longer service life in challenging conditions.

Retrofitting existing equipment with SF-1S bushings is typically straightforward, as they are available in standard sizes that match conventional bronze bushings. This makes the transition cost-effective, with many users reporting a rapid return on investment through reduced maintenance costs and extended service intervals. Industries ranging from agriculture to manufacturing are making the switch, recognizing the long-term benefits of this advanced bearing technology.

4. High-Load Capacity of SF-1S Bushings: Where Standard Bearings Fail

In demanding industrial applications where equipment must withstand substantial forces, bearing selection becomes critical to operational reliability. Standard bearings often prove inadequate when subjected to continuous heavy loads, leading to premature failure and costly downtime. The exceptional high load capacity self-lubricating stainless steel bushings of the SF-1S series provide a robust solution that maintains performance even under extreme mechanical stress.

The load-bearing capability of any bushing depends on multiple factors, including material composition, design geometry, and lubrication effectiveness. Traditional bearings typically rely on a combination of hard materials and external lubrication to handle heavy loads. However, this approach has inherent limitations - lubrication can break down under pressure, and hard materials may lack the necessary toughness for impact loads. SF-1S bushings address these challenges through their unique construction, combining high-strength stainless steel with embedded solid lubricants that maintain their properties under load.

Dynamic load capacity is particularly important in applications involving movement, such as oscillating machinery or rotating equipment. The self-lubricating properties of SF-1S bushings ensure consistent performance throughout the entire range of motion, preventing the stick-slip phenomenon that can occur with conventional bearings under heavy loads. This makes them ideal for use in hydraulic cylinders, where smooth movement under high pressure is essential for precise control and long service life.

Static load performance is equally impressive, with SF-1S bushings capable of supporting substantial weight without deformation. This characteristic proves invaluable in structural applications such as bridge bearings or support points in heavy machinery, where components must maintain dimensional stability under constant compression. Unlike polymer-based alternatives that can creep under sustained loads, the metal-backed design of SF-1S bushings provides reliable long-term performance.

Impact resistance represents another area where these bushings excel. In equipment subject to shock loads, such as mining machinery or construction equipment, standard bearings often fail due to brinelling or cracking. The combination of tough stainless steel and resilient lubricating layers in SF-1S bushings absorbs impact energy effectively, distributing forces across a wider area to prevent localized damage.

Real-world applications demonstrate the advantages of high-load SF-1S bushings in various industries. In press machinery, where components must withstand tremendous forces, these bushings have shown service lives three to five times longer than conventional alternatives. Similarly, in material handling equipment like crane sheaves, their ability to handle both radial and axial loads simultaneously reduces the need for complex bearing arrangements, simplifying design while improving reliability.

5. Corrosion-Resistant SF-1S Bushings for Marine & Offshore Equipment

The harsh marine environment presents unique challenges for mechanical components, with saltwater exposure accelerating corrosion and reducing service life. Traditional bearings often fail prematurely in these conditions, leading to increased maintenance costs and operational downtime. Corrosion-resistant SF-1S bushings for marine equipment provide an effective solution, combining stainless steel durability with self-lubricating properties to withstand the demanding conditions of offshore and coastal applications.

Saltwater corrosion affects marine equipment through multiple mechanisms, including galvanic reactions, pitting, and crevice corrosion. Standard bearing materials like carbon steel or bronze are particularly vulnerable to these degradation processes, often requiring protective coatings or frequent replacement. The stainless steel construction of SF-1S bushings provides inherent resistance to these corrosive effects, maintaining structural integrity even in continuous saltwater exposure.

Marine propulsion systems benefit significantly from these corrosion-resistant properties. Rudder bearings, for example, must operate reliably while constantly submerged in seawater. Traditional bearings in these applications typically require elaborate sealing systems to protect against water intrusion, adding complexity and potential failure points. SF-1S bushings eliminate this need, as their stainless steel construction resists corrosion while the self-lubricating feature prevents water washout of lubricants.

Offshore platform equipment faces even more extreme conditions, combining saltwater exposure with high loads and vibration. Mooring systems, crane sheaves, and other critical components demand bearings that can withstand these combined stresses without maintenance. The combination of corrosion resistance and self-lubrication in SF-1S bushings makes them ideal for these challenging applications, where reliability is paramount and maintenance opportunities may be limited.

Fishing vessel equipment presents another demanding application where corrosion resistance is essential. Winches, trawl blocks, and other deck machinery operate in wet conditions with constant salt spray exposure. The self-lubricating nature of SF-1S bushings prevents the binding that can occur when conventional bearings become contaminated with salt crystals, ensuring smooth operation throughout extended fishing expeditions.

Beyond marine vessels, coastal infrastructure such as bridges and harbor equipment also benefits from these corrosion-resistant bushings. Expansion joints, gate mechanisms, and other moving parts in these structures must endure decades of saltwater exposure without failure. The long service life and maintenance-free operation of SF-1S bushings make them a cost-effective solution for these critical applications, reducing lifecycle costs while improving reliability.

The advantages extend to specialized marine applications as well. Submersible equipment, desalination plants, and underwater research apparatus all require components that can resist corrosion while maintaining precise movement. In these environments, the combination of stainless steel durability and consistent self-lubrication provided by SF-1S bushings offers performance characteristics unmatched by conventional bearing solutions.