-

Industry News- Why is the Transfer Film Mechanism of a self lubricat...

Industry News- Why is the Transfer Film Mechanism of a self lubricat...In high-load and low-speed industrial applications, the transition toward maintenance-free components has prioritized the engineering of the...

-

Industry News- Can Switching to Self Lube Bearings Significantly Red...

Industry News- Can Switching to Self Lube Bearings Significantly Red...In the modern industrial landscape, the relentless pursuit of operational efficiency has led engineers to re-evaluate the most fundamental c...

-

Industry News- How Does a Bronze graphite bearing Maintain Consisten...

Industry News- How Does a Bronze graphite bearing Maintain Consisten...In heavy industrial applications where liquid lubricants vaporize or carbonize, the Bronze graphite bearing stands as a critical engineering...

-

Industry News- How to Accurately Calculate the Wear Life of a Self L...

Industry News- How to Accurately Calculate the Wear Life of a Self L...In the field of heavy-duty mechanical engineering, the reliability of a self lubrication bearing is critical for minimizing downtime and mai...

-

Industry News- How Do Self Lube Bearings Compare to Traditional Grea...

Industry News- How Do Self Lube Bearings Compare to Traditional Grea...In the demanding landscape of heavy industrial machinery, the choice between lubrication systems can dictate the entire lifecycle of a mecha...

-

0+Establishment

Founded in 2014, Shuangnuo has 10 years of experience in the industry.

-

0+Advanced Equipment

Strong production capacity ensures that we can organize material production for customers as soon as possible and shorten the production cycle.

-

0+Happy Clients

There are more than 5,000 cooperative customers around the world.

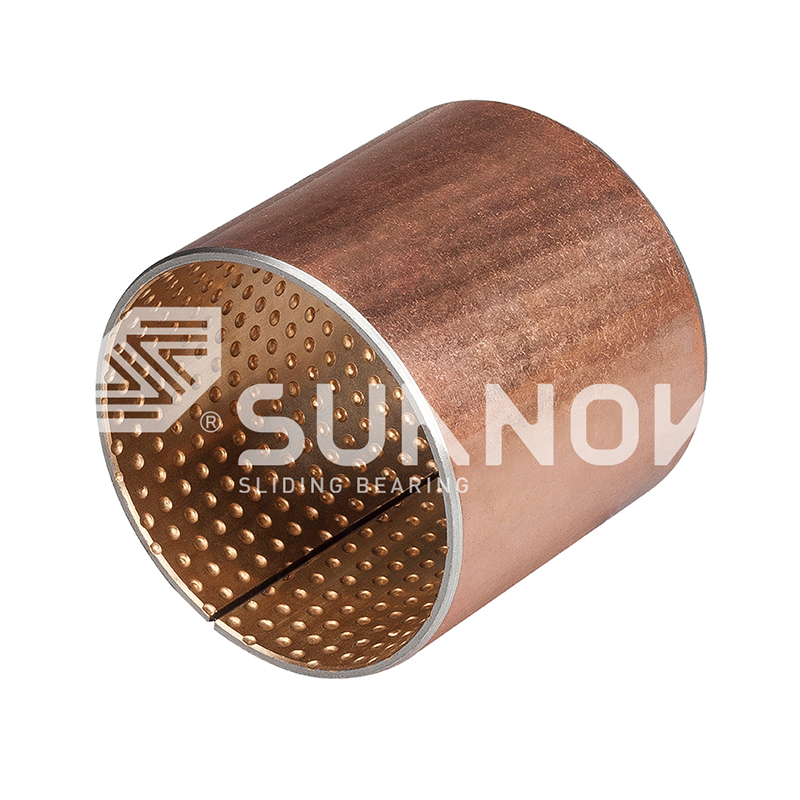

What are the precautions for the maintenance and care of JF-800 Bi-metal Bearing?

The maintenance and care of JF-800 Bi-metal Bearing is very important to extend its service life and ensure good working performance. Here are some key precautions:

1. Regular inspection

Check the wear condition: Check the wear degree of the bearing regularly, especially in high-load or high-speed applications.

Observe the oil film condition: Ensure that the oil film is intact, check the color and viscosity of the oil, and judge whether it needs to be replaced.

2. Lubrication

Choose the right lubricant: Use lubricating oil or grease suitable for JF-800 Bi-metal Bearing to ensure that it has good anti-wear and anti-oxidation properties.

Regular lubrication: According to the use environment and working conditions, formulate a lubrication plan and add lubricant regularly to avoid dry grinding and overheating.

3. Temperature control

Monitor the operating temperature: Ensure that the bearing is within the normal operating temperature range to avoid overheating and material performance degradation.

Heat dissipation design: If possible, design a good heat dissipation system to help keep the bearing running at an appropriate temperature.

4. Dust and dirt prevention

Protect the seal: Ensure that the seal of the bearing is intact to prevent dust and dirt from entering.

Clean the surrounding environment: Keep the working environment clean and avoid debris from entering the bearing area.

5. Load management

Avoid overloading: Strictly follow the manufacturer's load recommendations to avoid exceeding the rated load of the bearing.

Even load distribution: In a multi-bearing system, ensure that the load is evenly distributed to reduce local wear.

6. Regular maintenance

Develop a maintenance plan: Develop a regular maintenance plan, including lubrication, cleaning and inspection, to ensure that all work is carried out on time.

Record maintenance records: Keep maintenance and inspection records to track the use and maintenance history of the bearing.

7. Replacement timing

Identify replacement signals: If abnormal noise, vibration or overheating occurs, check and consider replacing the bearing in time.

Follow the replacement cycle: Reasonably arrange the replacement cycle of the bearing according to working conditions and wear.